Collaborative Innovation of Plain Weave Structure and Elastic Fiber

2025-07-10

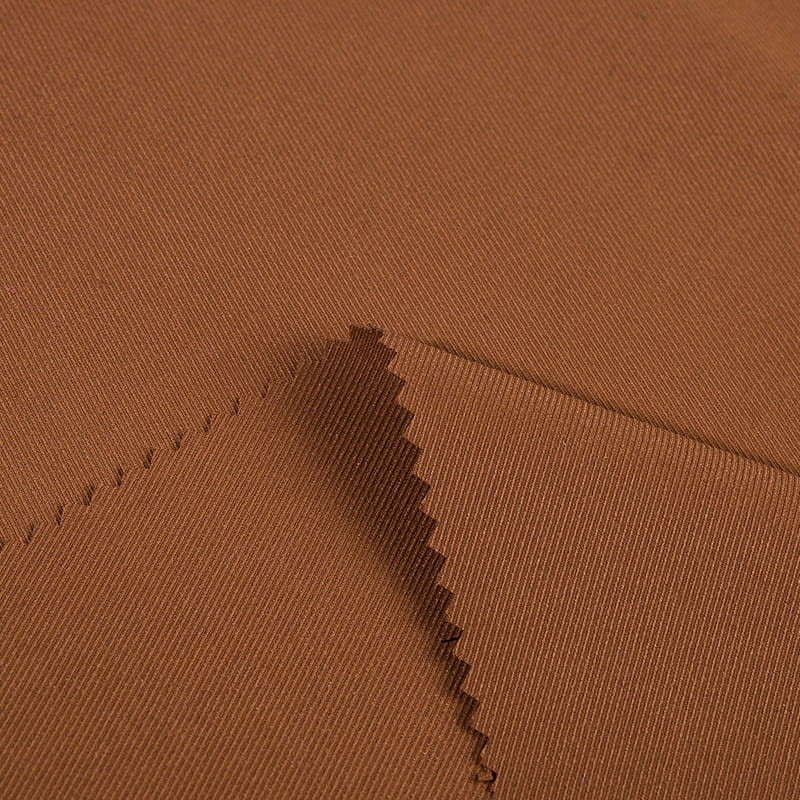

In the field of textile materials, machine pack plain stretch cloth has attracted much attention due to its unique performance advantages. To explore the secret of its performance, the regular arrangement of plain weave is undoubtedly the key to understanding its elastic performance.

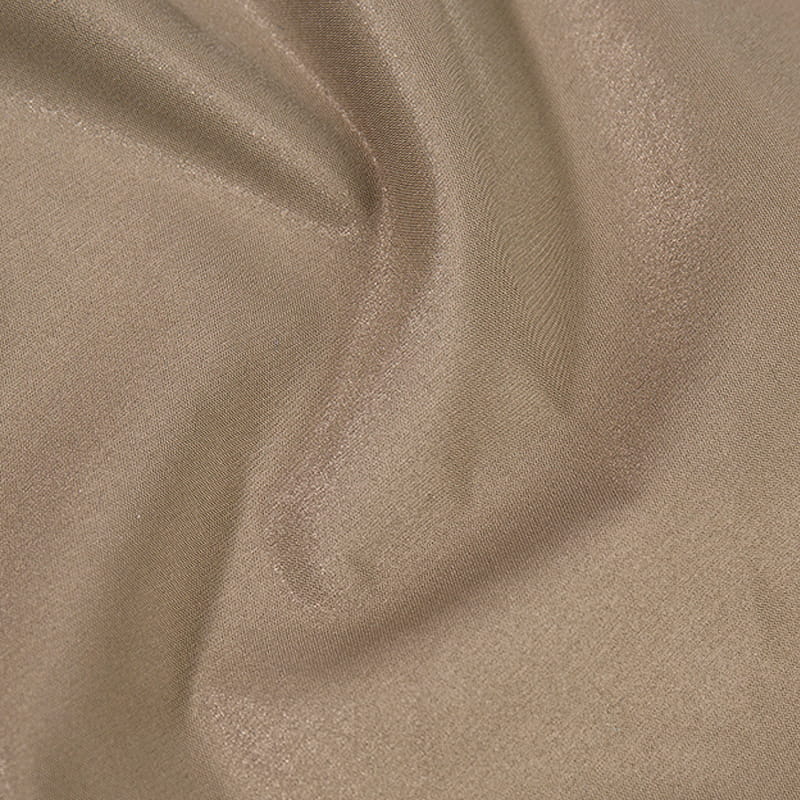

Basic structure and characteristics of plain weave

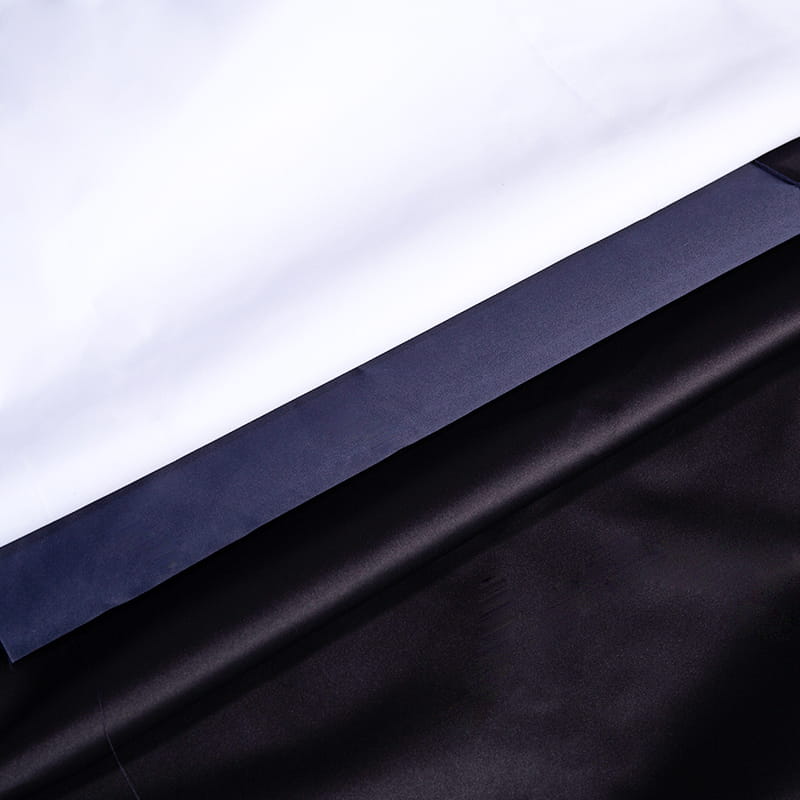

Machine pack plain stretch cloth is based on the classic plain weave structure. The warp and weft yarns follow the interweaving rule of one up and one down, forming a fine and uniform grid structure on the surface of the fabric. This regular arrangement makes the fabric present a tight and flat appearance in the unstretched state. The tight interweaving points between the warp and weft yarns give the fabric a higher density and also bring good wear resistance and tear resistance. While ensuring the stability of the fabric, the tight structure also limits the free movement space of the fiber itself, making the traditional plain fabric lack elasticity and difficult to meet the application scenarios that require stretchability.

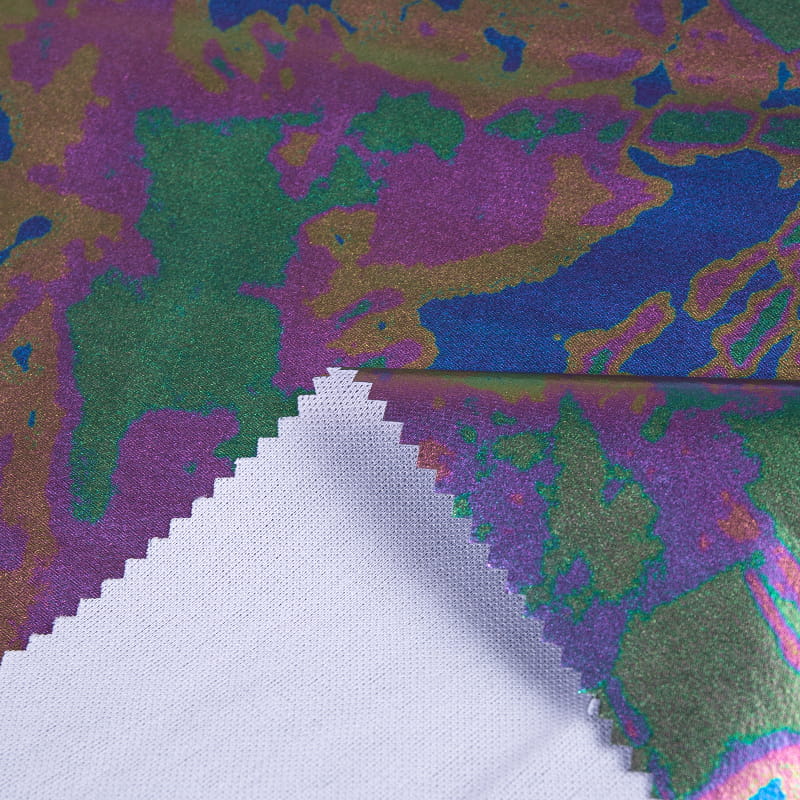

Intervention and mechanism of action of elastic fiber

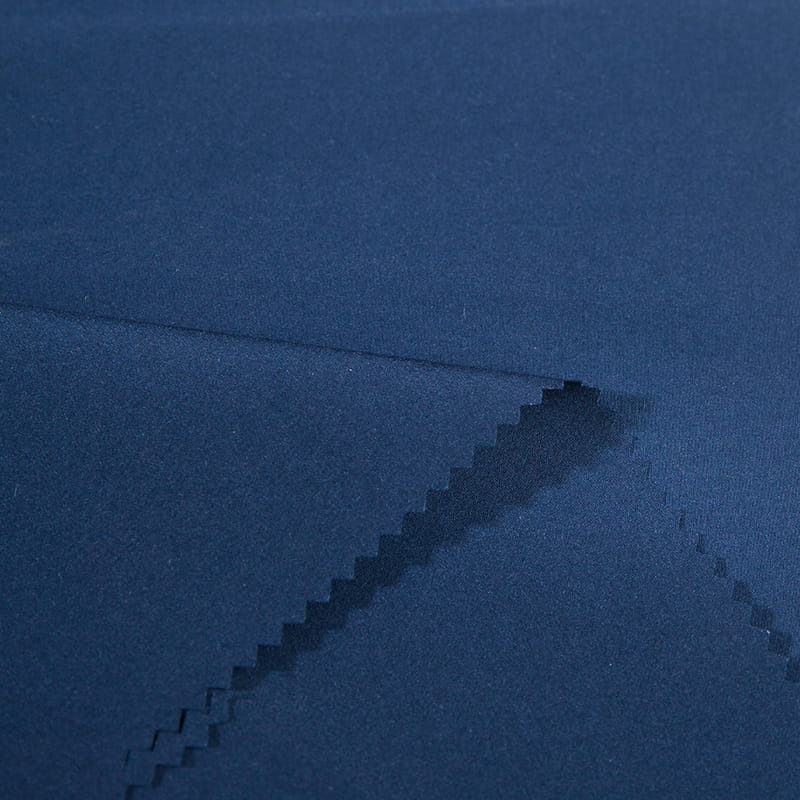

In order to break the elastic limitations of plain weave, the addition of elastic fibers such as spandex has become a key breakthrough point. When elastic fibers are integrated into the plain weave structure, it is like implanting a flexible "spring device" in the originally rigid frame. When external force acts, spandex yarn, with its high elasticity, stretches rapidly like a stretched spring, and the tension generated by its deformation drives the surrounding warp and weft yarns to rearrange and combine. This rearrangement of the yarn allows the fabric to be extended in the warp and weft directions or in one direction, thereby meeting the elasticity requirements of the fabric for human activities, clothing shaping, etc. When the external force is removed, the elastic fiber, with its resilience, will pull the stretched and displaced yarn back to its original position like a spring that returns to its original state, prompting the fabric to quickly return to its original shape, effectively avoiding the problem of relaxation and deformation.

Application advantages of rigid and flexible characteristics

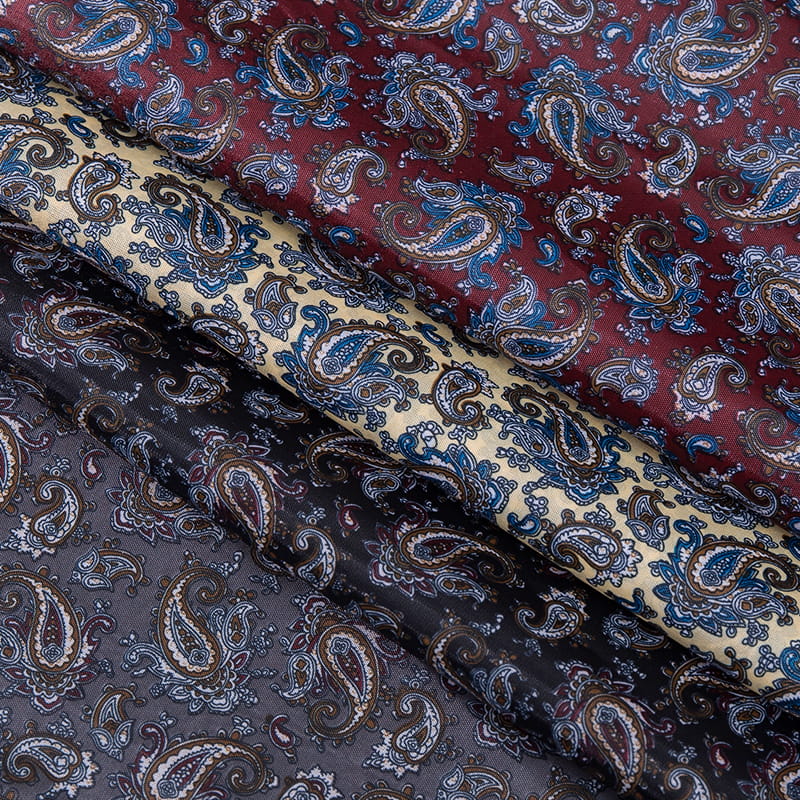

The rigid and flexible characteristics created by the combination of plain weave and elastic fiber allow machine pack plain stretch cloth to show unique application advantages in many fields. In the field of clothing production, its compact plain weave basic structure can provide stable support for clothing, facilitate three-dimensional cutting, and create straight and neat lines like suit pants; the elasticity given by the stretch fiber can ensure the comfort and flexibility of the wearer during activities, meet the dynamic fit requirements of sportswear such as yoga clothes, and allow the clothing to maintain a good appearance and adapt to various changes in human body movements. In non-clothing fields, such as medical bandages and automotive interiors, this combination of rigidity and flexibility also plays an important role. Medical bandages need to maintain stable pressure while fitting the curves of the human body. The elasticity of machine pack plain stretch cloth can achieve precise fitting, and the stability of its plain weave structure can ensure continuous and uniform pressure application; the use of this fabric in automotive interiors can not only adapt to the shape requirements of different parts through elasticity, but also rely on the characteristics of plain weave to maintain a long-term shape, ensuring the beauty and durability of the interior.

From the basic structure of plain weave, to the ingenious intervention of elastic fibers, to the final unique performance of both rigidity and flexibility, machine pack plain stretch cloth achieves a balance between functionality and comfort through exquisite structural design and material combination.

English

English русский

русский عربى

عربى