What Are the Key Advantages of Printing Polyester Fabric for Fashion Designers?

2026-02-16

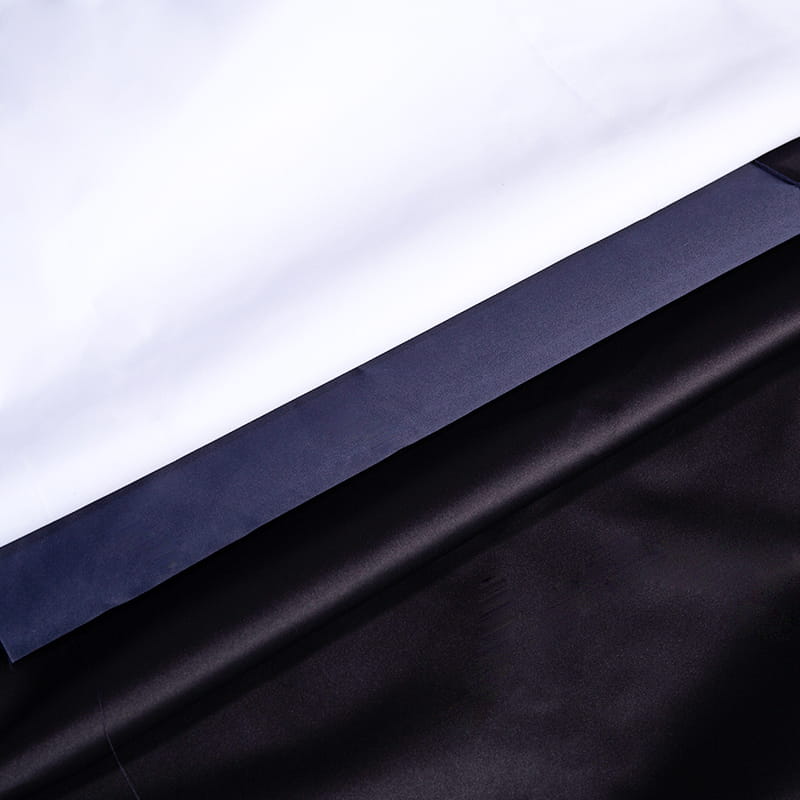

In the dynamic world of fashion design, material selection is a cornerstone of creativity and commercial success. Among the myriad of textiles available, printing polyester fabric has emerged as a dominant and versatile player. For designers navigating the balance between artistic vision, durability, cost, and production timelines, understanding the intrinsic benefits of this material is paramount. Polyester, a synthetic polymer, offers a unique canvas that excels in accepting vibrant dyes and intricate patterns through various digital printing on polyester techniques. Its performance characteristics make it indispensable for applications ranging from haute couture to high-street activewear. This article delves into the key advantages that make printed polyester a go-to choice for modern fashion designers, exploring its technical merits, creative possibilities, and practical applications in today's industry.

Unmatched Design Versatility and Vivid Color Reproduction

The primary allure of printing polyester fabric lies in its exceptional capacity for design freedom and color brilliance. Unlike natural fibers which can be inconsistent in dye absorption, polyester's manufactured structure provides a uniform, smooth surface. This consistency is ideal for modern digital printing on polyester, a technique that allows for photorealistic images, intricate gradients, and limitless patterns without the color registration limits of traditional screen printing. The hydrophobic nature of polyester fibers means dye-sublimation inks bond at a molecular level within the fiber itself, rather than sitting on the surface. This results in colors that are extraordinarily vibrant, resistant to fading, and deeply saturated. Designers are no longer constrained by traditional repeat patterns or color counts; they can print complex artworks, digital photographs, or watercolor-style designs directly onto the fabric with stunning accuracy. This capability is revolutionizing collections, enabling small-batch, on-demand production runs that are both economical and highly creative. Furthermore, the ability to achieve such vivid hues on both light and dark backgrounds expands the designer's palette exponentially.

- Photorealistic Potential: Perfect for printing detailed artwork, brand logos, and photographic images with crisp clarity.

- No Design Limits: Digital processes eliminate screens and plates, allowing for unlimited colors and seamless, all-over prints.

- Color Fastness: Sublimated dyes become part of the fiber, offering superior resistance to washing and sunlight compared to many printed natural fabrics.

- Rapid Prototyping: Enables quick sampling and design adjustments, accelerating the creative development cycle.

Comparing Print Techniques on Polyester

While digital sublimation is the star for complex designs, several printing methods are employed on polyester, each with its strengths. Understanding these best methods to print on polyester fabric allows designers to match the technique to the project's budget, volume, and desired effect. Dye-sublimation is optimal for full-color, all-over designs on white or light fabric. Direct-to-garment (DTG) printing offers flexibility for mixed-material garments but may require pretreatment on dark polyesters. Pigment printing can work but may affect the fabric's hand feel. The choice significantly impacts the final product's aesthetics, durability, and cost.

| Printing Method | Best For | Key Consideration for Designers |

| Dye-Sublimation | All-over patterns, vibrant colors, activewear, flags | Requires fabric with high polyester content (ideally white). Design is permanent and breathable. |

| Direct-to-Garment (DTG) | Detailed artwork on finished garments, low-volume runs | May require pretreatment; print layer can sit on top of fabric, potentially affecting stretch. |

| Pigment Printing | Simple graphics, cost-effective large runs on dark colors | Print can be stiff and may crack over time; less vibrant than sublimation. |

| Rotary Screen Printing | Very large volume runs of repeating patterns | High setup cost, limited color separations, less design flexibility than digital. |

Superior Performance and Durability for Diverse Applications

Fashion is not merely about aesthetics; it's about function and longevity. This is where printing polyester fabric truly shines, offering a suite of performance characteristics that natural fibers often struggle to match. Polyester is inherently strong, resistant to shrinking and stretching, and quick-drying. When prints are applied via dye-sublimation, they don't add a layer on top of the fabric; they become embedded within it. This means the print won't crack, peel, or wash away, and it maintains the fabric's original moisture-wicking and breathability properties—a critical factor for performance wear printing ideas. Designers creating swimwear, athletic apparel, outdoor gear, or even durable everyday fashion leverage these benefits to produce garments that look great and stand up to real-world use. The fabric's resilience also translates to excellent wrinkle resistance, making it ideal for travel clothing and items that need to maintain a pristine appearance with minimal care. This durability extends the lifecycle of the garment, aligning with more sustainable consumption patterns by reducing the need for frequent replacement.

- Moisture Management: Essential for sportswear; printed polyester wicks sweat away from the body, keeping the wearer dry and comfortable.

- Shape Retention: Garments hold their fit wash after wash, without the sagging or shrinking common in cottons.

- Low Maintenance: Often machine washable, quick-drying, and requiring little to no ironing, enhancing customer satisfaction.

- Abrasion Resistance: Withstands friction and wear, making it perfect for backpacks, uniforms, and children's clothing.

Idea Spotlight: Performance and Athletic Wear

The synergy between polyester's performance traits and modern printing has sparked innovation in activewear. Designers are moving beyond simple logos to integrate functional artistry. Performance wear printing ideas include using sublimated prints to create optical illusions that enhance the perception of an athlete's physique, mapping gradient colors to indicate muscle groups, or incorporating motivational graphics seamlessly into the fabric. The technical process ensures these designs do not impede elasticity or breathability, a non-negotiable requirement in high-performance sectors.

Cost-Effectiveness and Sustainable Production Potential

From a business standpoint, the economics of printing polyester fabric are compelling. The fabric itself is generally less expensive to produce than high-quality natural fibers like silk, linen, or organic cotton. When combined with digital printing on polyester, it enables a highly efficient production model. Digital printing eliminates the need for costly screens, plates, and minimum yardage requirements associated with traditional printing. This makes short runs and on-demand manufacturing financially viable, drastically reducing waste from overproduction and deadstock—a significant concern in the fashion industry. Designers can test the market with small collections, offer customization, and reorder based on demand without massive upfront investment. Furthermore, advances in polyester fabric printing for beginners have made entry into printed textile design more accessible than ever, with numerous print-on-demand services handling the technical production. On the sustainability front, while polyester's petroleum-based origin is a drawback, its durability and the efficiency of digital printing present a lifecycle argument. Additionally, the growing use of recycled polyester (rPET) from plastic bottles offers a more eco-friendly substrate for printing, allowing designers to create vibrant collections with a reduced environmental footprint.

- Reduced Setup Costs: No screens or plates needed for digital printing, lowering barriers for small collections.

- On-Demand Model: Print only what is sold, minimizing inventory waste and aligning with slow fashion principles.

- Accessibility: Services exist that handle the entire printing process, allowing designers to focus solely on creation.

- Recycled Material Integration: Printing on rPET fabric combines vibrant design with a compelling sustainability story.

Practical Applications: From Runway to Retail

The theoretical advantages of printing polyester fabric materialize across the entire spectrum of fashion. On the runway, designers utilize its capabilities for dramatic, flowing gowns with impossible prints or structured pieces with bold, graphic statements. In streetwear, it's the foundation for vibrant hoodies, jackets, and accessories that define youth culture. The care for printed polyester clothing is straightforward, enhancing its appeal to the end-consumer. For special niches like dancewear, swimwear, and team uniforms, its combination of aesthetics, stretch, and chlorine/sun resistance is unbeatable. Even in home textiles, printed polyester is used for durable, colorful curtains and upholstery. Understanding the polyester printing quality factors—such as fabric weave, weight, and finish—is crucial for designers to select the right base material for their specific application, ensuring the final product performs as intended.

- Runway & Avant-Garde: Enables experimental, unwearable-art concepts to become wearable due to the fabric's durability and print fidelity.

- Swimwear & Activewear: The industry standard due to chlorine/UV resistance, stretch recovery, and vibrant, fade-resistant prints.

- Promotional & Corporate Wear: Ideal for uniforms and branded merchandise where logo clarity, durability, and cost are key.

- Accessories: Used in bags, scarves, and hats where colorfastness and structural integrity are important.

Ensuring Longevity: A Guide to Quality and Care

The longevity of a printed polyester garment hinges on two elements: initial polyester printing quality factors and ongoing care for printed polyester clothing. High-quality printing uses premium inks with proper fixation and selects the right fabric GSM (weight) for the end-use. Consumers play a role by following simple care instructions that preserve the print's vibrancy and the fabric's properties for years.

| Quality Factor | Impact on Final Product |

| Fabric Weight (GSM) | Lighter weights for drapey garments; heavier weights for structured items or outerwear. |

| Ink Type & Fixation | Properly sublimated dyes are permanent; poor fixation leads to fading and crocking (rubbing off). |

| Fabric Finish | Moisture-wicking, UV-resistant, or antimicrobial finishes add functional value to the printed fabric. |

| Print Resolution | Measured in DPI (dots per inch); higher DPI results in sharper, more detailed imagery. |

FAQ

What is the best printing method for polyester fabric for vibrant, all-over designs?

The unequivocally best method to print on polyester fabric for vibrant, seamless, all-over designs is dye-sublimation printing. This process uses heat to turn solid dye particles into a gas that permeates the polyester fibers and solidifies within them. Because the dye becomes part of the fiber, the results are exceptionally bright, colorfast, and do not affect the fabric's hand feel or breathability. It is the industry standard for activewear, swimwear, and fashion items where design coverage and durability are paramount. Other methods like direct-to-garment (DTG) can be used but often result in a surface print layer that may feel different and be less durable on 100% polyester.

How do I properly care for my printed polyester clothing to make the print last?

Care for printed polyester clothing, especially when dyed-sublimated, is refreshingly simple but crucial for longevity. Always turn the garment inside out before washing. Use cold or warm water (not hot) and a mild detergent. Avoid bleach or harsh stain removers, as these can damage the colors. Tumble dry on a low heat setting or, even better, air dry to conserve energy and minimize any thermal stress. Ironing is rarely needed, but if necessary, use a low heat setting and avoid direct contact with the printed area. Proper care ensures that the printing polyester fabric maintains its vivid appearance and functional properties for the life of the garment.

Can I achieve good print quality on polyester as a beginner designer?

Absolutely. The digital revolution has made polyester fabric printing for beginners highly accessible. You don't need to own industrial equipment. Many online print-on-demand (POD) platforms and local printing bureaus specialize in turning your digital artwork into printed fabric or finished garments. The key is to start with high-resolution artwork (typically 150-300 DPI at the final print size) and understand the color profiles (RGB for digital design, converted to the printer's specific color profile for accuracy). Partnering with a reputable printer who can provide fabric samples and guidance is an excellent first step to ensure your polyester printing quality factors are met from the outset.

What are some creative printing ideas for polyester performance wear?

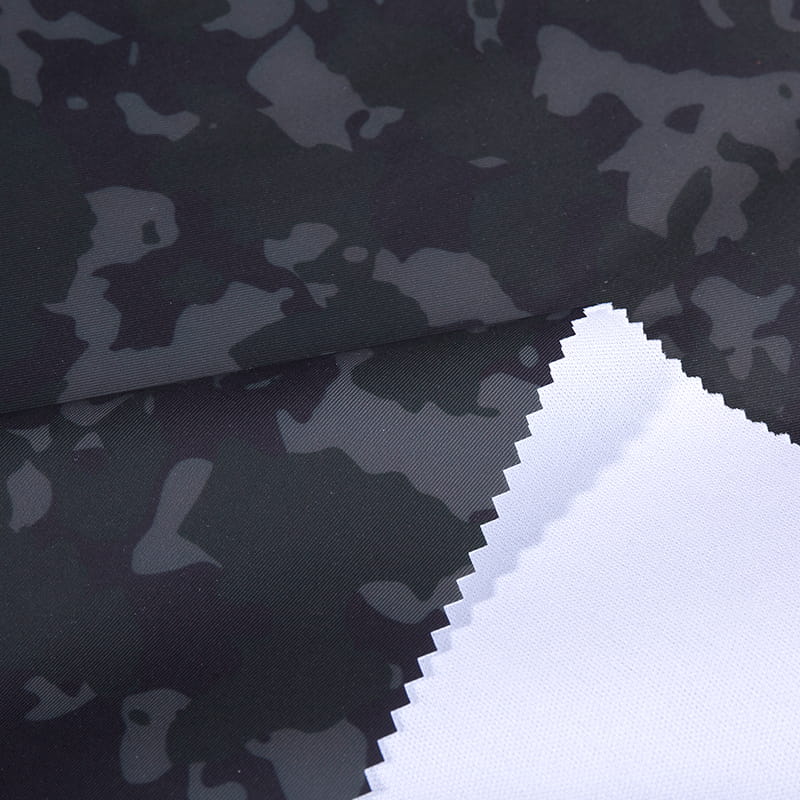

The field of performance wear printing ideas is vast and innovative. Beyond team logos, consider these concepts: 1) Anatomical Mapping: Use gradient prints that follow muscle contours to visually enhance an athlete's physique. 2) Camouflage & Disruption: Create unique, abstract patterns that break up the body's lines in sports like training or outdoor activities. 3) Motivational & Data-Inspired Graphics: Integrate subtle typography, mantra patterns, or graphics inspired by heart rate zones or topographic maps. 4) Thermochromatic or Reflective Elements: Incorporate inks that change color with body heat or reflect light for safety in low-light conditions. These ideas leverage the technical superiority of printing polyester fabric to add both style and function.

Is printed polyester fabric considered sustainable?

The sustainability of printing polyester fabric is a nuanced topic. Traditional polyester is derived from non-renewable petroleum, and its production is energy-intensive. However, its significant durability and long life can offset its initial footprint by reducing replacement frequency. The most substantial sustainability gains come from combining digital printing (which drastically reduces water and ink waste compared to traditional methods) with recycled polyester (rPET) fabric. rPET is made from post-consumer plastic bottles, diverting waste from landfills. When designers choose to print on rPET using efficient digital sublimation, they create a product with a compelling environmental narrative, addressing concerns about microplastics through garment longevity and end-of-life recycling programs.

English

English русский

русский عربى

عربى