Durable PVC PU Coating Oxford Fabric for Outdoor and Industrial Use

2025-10-14

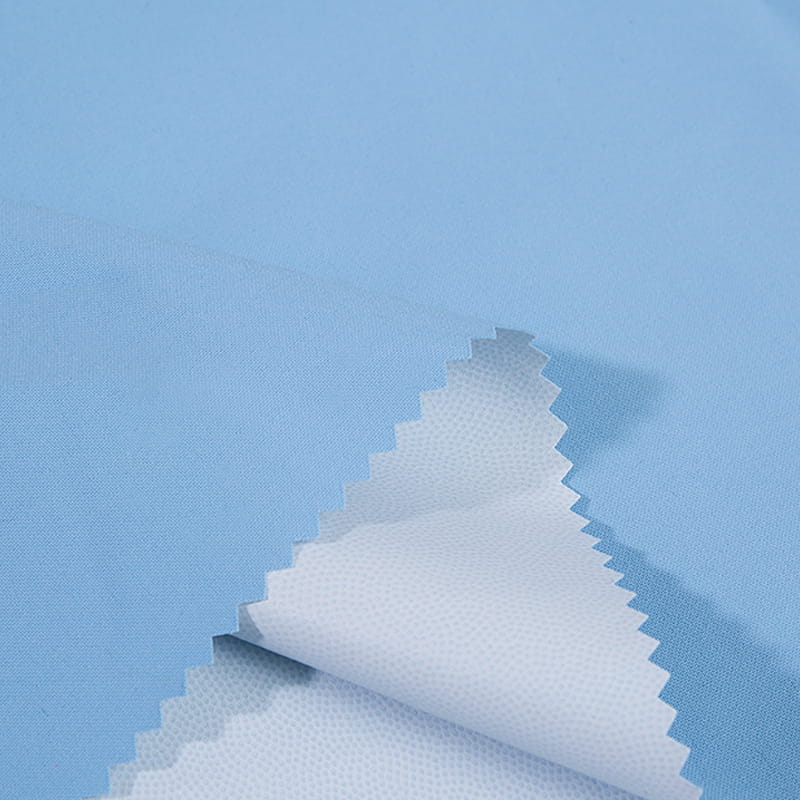

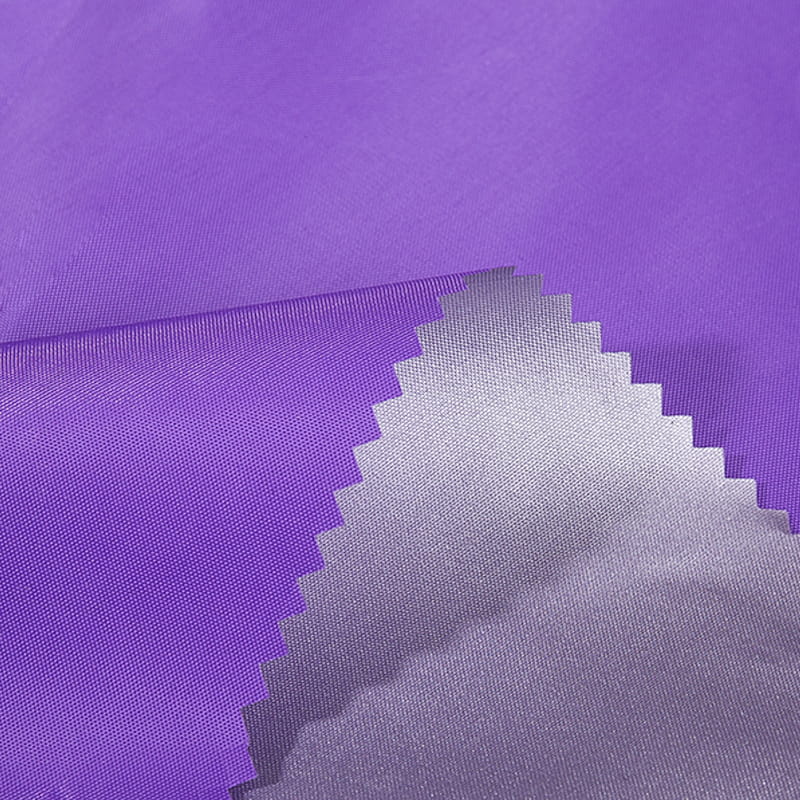

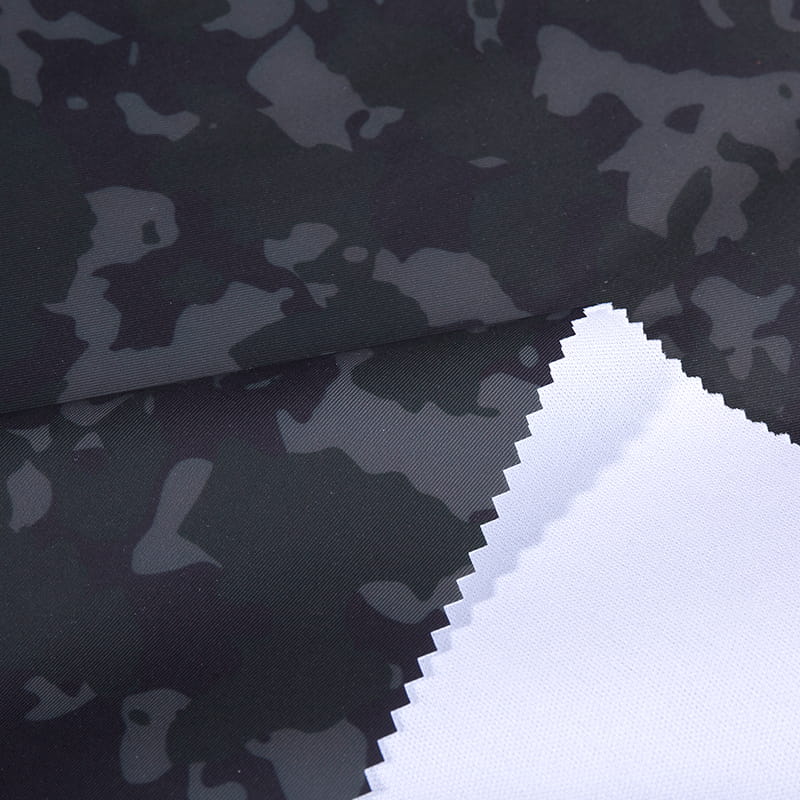

Understanding PVC and PU Coated Oxford Fabric

Oxford fabric has long been recognized as a versatile and durable material, but when combined with PVC (Polyvinyl Chloride) or PU (Polyurethane) coatings, its properties are significantly enhanced. This combination creates a fabric that is not only strong and resistant to wear and tear but also capable of withstanding harsh environmental conditions. The base Oxford fabric is typically made from a synthetic fiber, woven in a specific pattern that gives it a characteristic textured appearance. The application of PVC or PU coatings adds a layer of protection, making the fabric waterproof, resistant to chemicals, and easy to clean. This makes it an ideal choice for a wide range of applications, from outdoor gear like tents and tarps to industrial uses such as protective covers and machinery guards. The durability of this fabric is one of its most valued attributes, ensuring that products made from it have a long service life even under demanding conditions.

The manufacturing process involves applying the coating to the woven Oxford fabric, which can be done in various thicknesses and finishes depending on the intended use. For instance, a heavier coating might be used for industrial applications where abrasion resistance is crucial, while a lighter, more flexible coating might be preferred for outdoor apparel. The result is a material that balances strength with flexibility, offering excellent performance across different scenarios. Understanding the fundamental aspects of PVC and PU coated Oxford fabric is essential for selecting the right type for specific needs, whether for personal use or large-scale industrial projects.

Key Long-Tail Keywords for PVC PU Coating Oxford Fabric

To effectively reach audiences searching for information on this material, it's important to target specific long-tail keywords that have decent search volume but lower competition. These keywords help in attracting qualified traffic who are looking for detailed information or specific solutions. Below are five relevant long-tail keywords that meet these criteria:

- waterproof pvc coated oxford fabric for tarps

- heavy duty pu coated oxford cloth for bags

- fire resistant pvc oxford fabric for industrial covers

- lightweight pu coated oxford material for outdoor gear

- uv resistant pvc pu oxford fabric for awnings

These keywords will be integrated throughout the article to ensure comprehensive coverage and SEO optimization, helping readers find the exact information they need regarding the applications and benefits of PVC PU coated Oxford fabric.

Applications of Coated Oxford Fabric in Various Industries

The versatility of PVC and PU coated Oxford fabric makes it suitable for a broad spectrum of applications. Its unique properties, such as water resistance, durability, and ease of maintenance, allow it to be used in environments where other materials might fail. Below, we explore some of the key industries and uses where this fabric excels.

Outdoor and Recreational Uses

In the outdoor sector, coated Oxford fabric is a popular choice for items that need to withstand the elements. This includes products like tents, backpacks, and camping gear, where exposure to rain, wind, and UV rays is common. The fabric's ability to repel water and resist mildew ensures that these items remain functional and comfortable over time. For example, waterproof pvc coated oxford fabric for tarps is often used in camping tarps and shelters because it provides reliable protection against heavy rain and moisture. Additionally, its robustness means it can handle rough terrain and frequent use without tearing or degrading. Another advantage is its lightweight nature, which is crucial for portable equipment; lightweight pu coated oxford material for outdoor gear offers the same protective qualities without adding unnecessary weight, making it ideal for hikers and outdoor enthusiasts who need to carry their gear over long distances.

Beyond camping, this fabric is also used in outdoor furniture covers, boat covers, and even sporting goods. The UV resistance in some variants prevents color fading and material weakening when exposed to prolonged sunlight, ensuring that products like awnings and canopies maintain their appearance and integrity. For instance, uv resistant pvc pu oxford fabric for awnings is specifically treated to reflect harmful UV rays, extending the life of outdoor structures. This makes it a cost-effective solution for both residential and commercial outdoor settings, where durability and weather resistance are paramount.

Industrial and Commercial Applications

In industrial settings, the demands on materials are often higher, requiring enhanced resistance to chemicals, abrasion, and extreme temperatures. Coated Oxford fabric meets these challenges head-on, making it a go-to material for protective covers, machinery enclosures, and safety equipment. For example, fire resistant pvc oxford fabric for industrial covers is essential in environments where sparks, flames, or high temperatures are present, such as in welding shops or near machinery that generates heat. This type of fabric is treated with fire-retardant chemicals that reduce flammability, providing an added layer of safety. Similarly, heavy duty pu coated oxford cloth for bags is used in industrial bags and carriers that need to transport heavy or sharp objects without puncturing or tearing. The PU coating adds a layer of flexibility and strength, allowing the fabric to withstand rough handling and heavy loads.

Other industrial applications include use in conveyor belts, temporary shelters, and partition curtains. The fabric's resistance to oils, greases, and other chemicals makes it suitable for factories and workshops where spills are common. Moreover, its ease of cleaning—often requiring just a wipe-down with a damp cloth—reduces maintenance time and costs. This practicality, combined with long-lasting performance, makes coated Oxford fabric a valuable asset in industries ranging from manufacturing to logistics, where efficiency and reliability are key.

Comparing PVC and PU Coatings on Oxford Fabric

When choosing between PVC and PU coatings on Oxford fabric, it's important to understand their differences in terms of performance, durability, and suitability for specific applications. Both coatings offer distinct advantages, and the choice often depends on factors such as environmental conditions, intended use, and budget. Below, we break down the key characteristics of each coating type to help you make an informed decision.

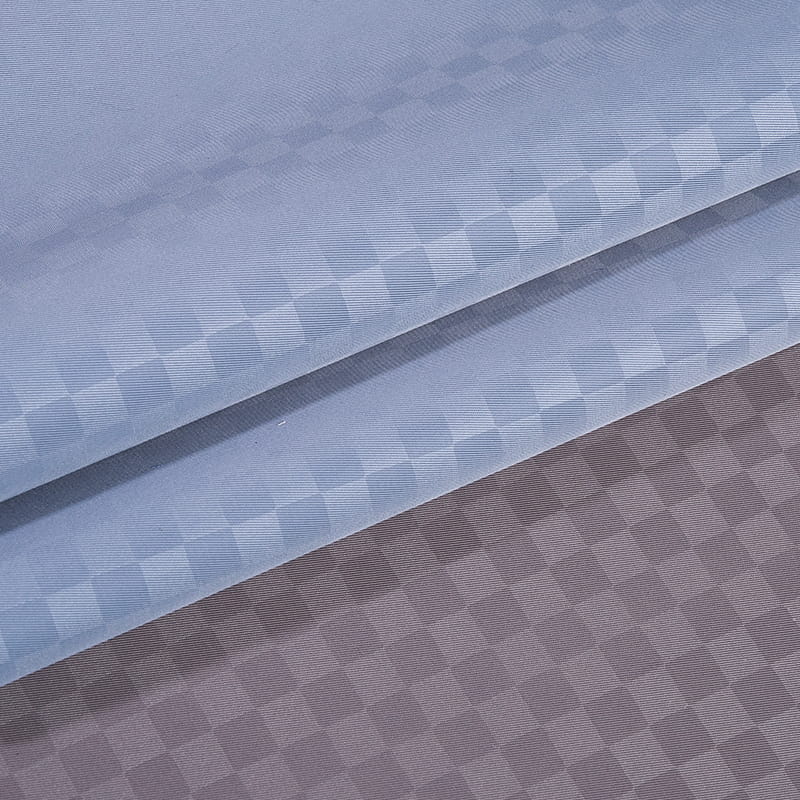

Key Differences in Material Properties

PVC coatings are known for their exceptional durability and resistance to abrasion, chemicals, and water. They form a thick, rigid layer on the fabric, which makes them ideal for heavy-duty applications like industrial covers or outdoor tarps. However, PVC can be less flexible than PU, which might limit its use in items that require frequent folding or movement. On the other hand, PU coatings are typically thinner and more flexible, offering a softer feel while still providing good water resistance and protection. This flexibility makes PU-coated fabric suitable for applications like bags or apparel, where comfort and mobility are important. Additionally, PU coatings are often more environmentally friendly, as they can be produced without harmful plasticizers commonly found in PVC.

Another key difference lies in their resistance to elements. PVC tends to perform better in extreme temperatures and UV exposure, whereas PU may degrade faster under prolonged sunlight if not specially treated. For example, uv resistant pvc pu oxford fabric for awnings often combines the best of both worlds, but pure PVC variants might offer superior longevity in harsh climates. In terms of cost, PVC is generally more affordable, but PU provides a higher-end finish that might be preferable for consumer goods. The table below summarizes these differences for easy comparison.

| Property | PVC Coating | PU Coating |

|---|---|---|

| Durability | High resistance to abrasion and tears | Good resistance, but more flexible |

| Water Resistance | Excellent, forms a solid barrier | Very good, but may require re-treatment over time |

| Flexibility | Rigid, less pliable | Soft and highly flexible |

| Environmental Impact | Contains plasticizers, less eco-friendly | Often more sustainable and recyclable |

| Cost | Generally lower | Higher due to manufacturing process |

| Common Uses | Industrial covers, tarps, heavy-duty bags | Outdoor gear, fashion bags, protective clothing |

Benefits of Using Coated Oxford Fabric in Manufacturing

The adoption of PVC and PU coated Oxford fabric in manufacturing processes brings numerous advantages, from improved product longevity to reduced maintenance costs. These benefits stem from the fabric's inherent properties, which are enhanced by the coatings to meet specific industrial or consumer needs. Below, we delve into the key benefits that make this material a preferred choice across sectors.

Enhanced Durability and Longevity

One of the primary reasons for choosing coated Oxford fabric is its exceptional durability. The combination of a tightly woven base fabric with a protective coating results in a material that can withstand physical stress, environmental factors, and frequent use. For instance, heavy duty pu coated oxford cloth for bags ensures that bags used in logistics or travel maintain their integrity even when subjected to heavy loads or rough handling. This durability translates to a longer lifespan for products, reducing the need for frequent replacements and thereby lowering long-term costs. In industrial contexts, where equipment covers or protective barriers are exposed to harsh conditions, this resilience is invaluable. Moreover, the fabric's resistance to mold, mildew, and UV rays means that it remains functional and aesthetically pleasing over time, even in challenging environments.

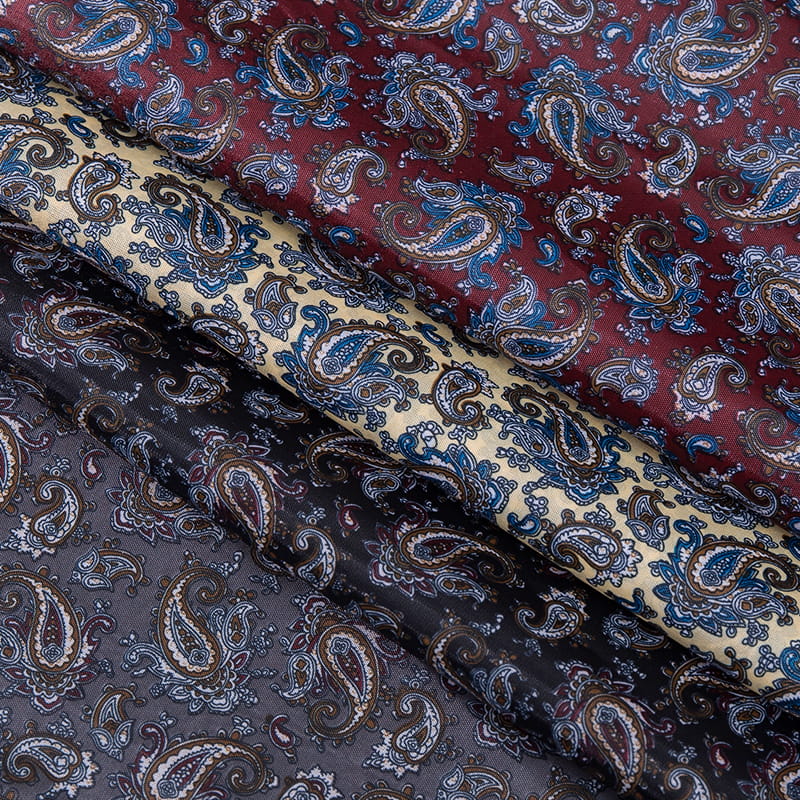

Versatility and Customization

Another significant benefit is the fabric's versatility. It can be manufactured in various weights, colors, and finishes to suit specific applications. For example, lightweight pu coated oxford material for outdoor gear can be tailored to be both strong and easy to carry, while fire resistant pvc oxford fabric for industrial covers can be treated with additional chemicals to meet safety standards. This customization extends to printing and branding, allowing manufacturers to add logos or designs without compromising the fabric's properties. The ability to adapt the material to different needs makes it a cost-effective solution for businesses that require tailored solutions without investing in entirely new materials. Whether for consumer products like backpacks or industrial items like machinery guards, coated Oxford fabric offers the flexibility to meet diverse requirements.

Selecting the Right Coated Oxford Fabric for Your Needs

Choosing the appropriate type of coated Oxford fabric depends on several factors, including the intended application, environmental conditions, and budget constraints. Making the right selection ensures that the fabric performs as expected and delivers value over its lifetime. Here, we provide guidance on how to evaluate your options and pick the best fit for your project.

Factors to Consider

When selecting coated Oxford fabric, start by assessing the primary use case. For outdoor applications, such as waterproof pvc coated oxford fabric for tarps, focus on water resistance, UV protection, and weight. If the fabric will be used in industrial settings, prioritize factors like chemical resistance, fire retardancy, and abrasion tolerance. For example, fire resistant pvc oxford fabric for industrial covers might be necessary in high-risk areas, while uv resistant pvc pu oxford fabric for awnings would be better for sun-exposed structures. Additionally, consider the fabric's thickness and coating type—PVC for heavy-duty, rigid needs or PU for flexible, lightweight requirements. It's also important to evaluate the fabric's environmental impact, especially if sustainability is a concern. PU coatings are often preferred for their eco-friendly properties, but advancements in PVC production have led to more sustainable options as well.

Other considerations include ease of maintenance, color fastness, and compliance with industry standards. For instance, fabrics used in safety equipment may need to meet specific regulatory requirements. By carefully weighing these factors, you can identify the ideal coated Oxford fabric that balances performance, cost, and longevity. Consulting with suppliers or conducting small-scale tests can also help in making an informed decision, ensuring that the material meets your expectations in real-world conditions.

Future Trends in Coated Oxford Fabric Technology

The world of coated textiles is continuously evolving, with innovations aimed at enhancing performance, sustainability, and usability. For PVC and PU coated Oxford fabric, several trends are shaping the future, making this material even more appealing for a wide range of applications. Understanding these trends can help industries and consumers stay ahead of the curve and leverage the latest advancements.

Innovations in Sustainability

As environmental concerns grow, there is increasing demand for eco-friendly coated fabrics. Manufacturers are developing PVC and PU coatings that use fewer harmful chemicals, are recyclable, or are derived from renewable sources. For example, bio-based PU coatings are gaining traction, offering similar performance to traditional options but with a reduced carbon footprint. Additionally, recycling programs for coated Oxford fabric are being explored, allowing end-of-life products to be repurposed rather than discarded. These innovations not only benefit the environment but also appeal to environmentally conscious consumers and businesses looking to improve their sustainability credentials.

Smart Textiles and Functional Enhancements

Another emerging trend is the integration of smart technologies into coated fabrics. This includes features like embedded sensors for monitoring environmental conditions, self-healing coatings that repair minor damages automatically, and temperature-regulating properties that enhance comfort in outdoor gear. For instance, future iterations of lightweight pu coated oxford material for outdoor gear might include moisture-wicking capabilities or UV-sensitive coatings that change color to indicate exposure levels. These advancements could revolutionize how coated Oxford fabric is used, making it not just a protective material but a multifunctional one that adds value beyond basic durability. As research and development continue, we can expect to see more innovative applications that push the boundaries of what this fabric can achieve.

English

English русский

русский عربى

عربى