The Ultimate Guide to Satin Poly Pongee: Properties, Uses, and Selection

2025-10-09

In the world of textiles, certain fabrics stand out for their unique blend of aesthetics and functionality. Satin Poly Pongee is one such material, a sophisticated synthesis that offers a remarkable set of characteristics. This comprehensive guide delves deep into the essence of this fabric, exploring its properties, diverse applications, and how to select the perfect type for your needs. Whether you are a designer, manufacturer, or simply a textile enthusiast, understanding the nuances of Satin Poly Pongee can unlock new possibilities for your projects.

What is Satin Poly Pongee? Defining the Fabric

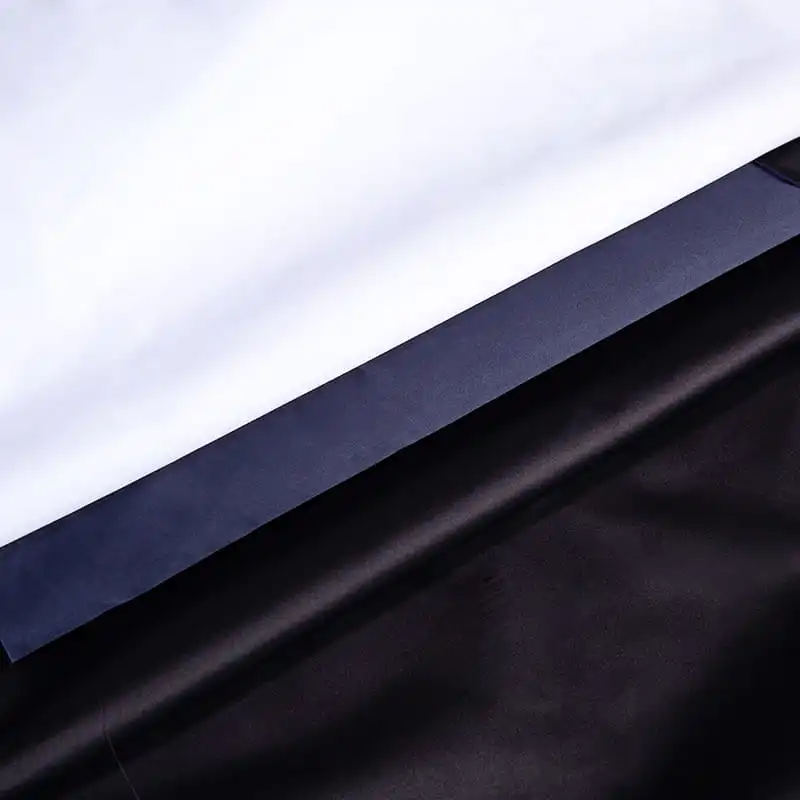

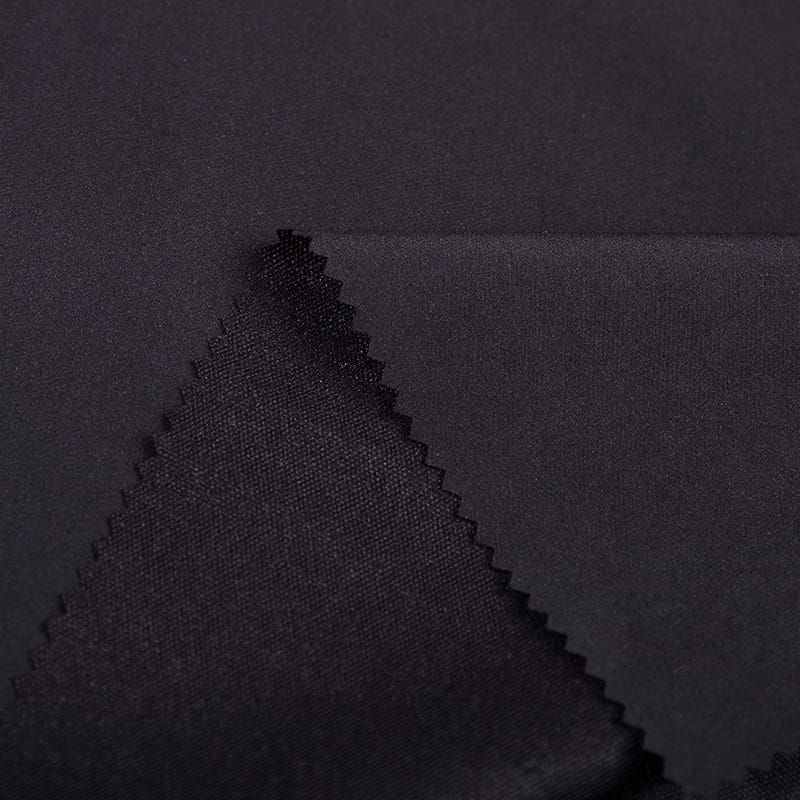

To understand Satin Poly Pongee, it's best to break down its name. It is a hybrid fabric that combines the best of two worlds: the structure of pongee and the finish of satin, all made from polyester fibers. Pongee is traditionally a plain-weave fabric known for its durability and slightly nubby texture, often made from silk or cotton. However, in this case, the base is constructed from polyester filaments, making it more resilient and affordable. The 'satin' refers to the weave technique employed. A satin weave is characterized by multiple warp yarns floating over a weft yarn, creating a smooth, lustrous surface on one side and a duller back. Therefore, Satin Poly Pongee is a polyester fabric using a satin weave structure, resulting in a material that is strong, lightweight, and has a luxurious, glossy appearance.

The Core Characteristics of the Material

Satin Poly Pongee is renowned for a specific set of physical properties that make it highly desirable for various applications. Its defining traits are a direct result of its polyester composition and satin weave pattern.

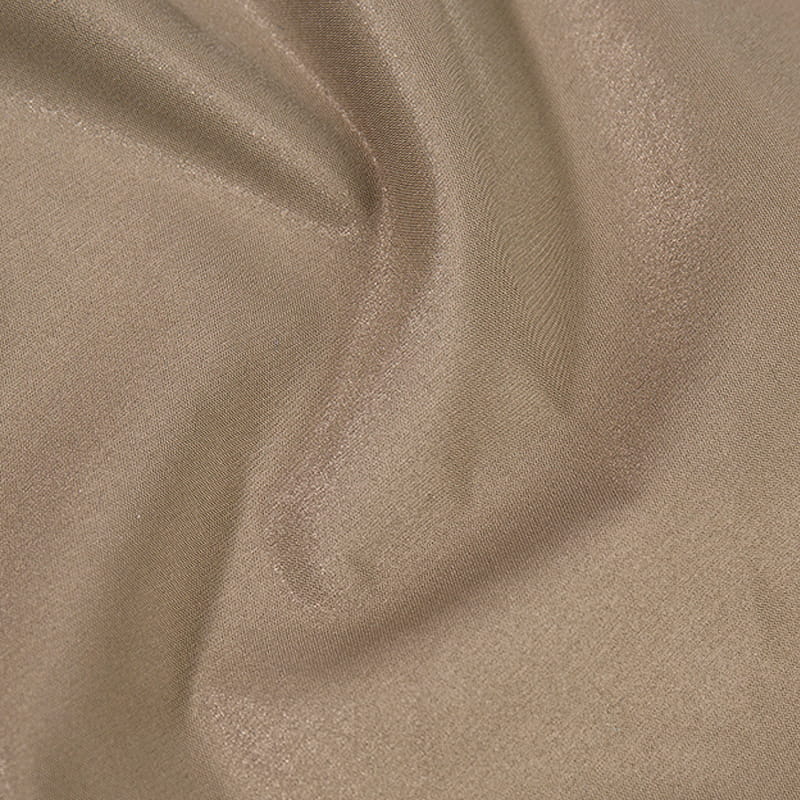

- High Luster and Smooth Feel: The satin weave creates a continuous surface of polyester filaments, reflecting light evenly to produce a characteristic sheen that is immediately associated with luxury. The front face is incredibly smooth to the touch.

- Exceptional Durability and Strength: Polyester fibers are inherently strong, resistant to stretching, shrinking, and most common abrasions. This makes the fabric far more robust than its natural satin counterparts.

- Water and Wind Resistance: The tightness of the satin weave, combined with the low moisture absorption of polyester, gives the fabric inherent resistance to light rain and wind, making it suitable for outerwear applications.

- Lightweight and Easy Care: Despite its strength, the fabric remains remarkably lightweight. It is also wrinkle-resistant and easy to wash, requiring little ironing, which adds to its practicality.

Exploring Key Applications and Uses of Satin Poly Pongee

The unique combination of beauty and brawn in Satin Poly Pongee opens doors to a wide array of uses, spanning from high fashion to practical industrial applications. Its versatility is one of its greatest assets.

Fashion and Apparel Innovations

In the apparel industry, Satin Poly Pongee is a favored material for designers seeking a luxurious look without a luxurious price tag or high maintenance. It is extensively used in the creation of lingerie, nightwear, and linings for jackets and coats. The smooth surface feels comfortable against the skin, and its durability ensures the garments maintain their shape and appearance over time. Beyond innerwear, it is also a popular choice for elegant evening wear, blouses, and neckties, where its drape and shine are visually appealing. A significant trend is its use in lightweight jackets and raincoats, capitalizing on its water-resistant properties.

Beyond Clothing: Home and Industrial Uses

The application of this fabric extends far beyond the wardrobe. In the home furnishing sector, it is used for decorative items like cushion covers, draperies, and tablecloths, adding a touch of elegance to interior spaces. Its resistance to fading makes it excellent for items exposed to sunlight. Industrially, its strength and resistance to elements make it a prime candidate for waterproof satin poly pongee for umbrellas and rainwear. The fabric's tight weave provides a reliable barrier against water, while its smooth surface allows rainwater to bead up and roll off easily. This specific application demands a high-quality finish to ensure consistent waterproofing, which is a key reason why manufacturers seek out specialized grades of this material.

Advantages of Choosing Satin Poly Pongee Over Other Fabrics

When selecting a fabric, it's crucial to weigh the pros and cons. Satin Poly Pongee holds distinct advantages over several other common textiles, particularly when balancing cost, performance, and aesthetics.

Comparison with Natural Silk and Other Satins

While natural silk satin is the benchmark for luxury, Satin Poly Pongee provides a compelling alternative. The most immediate difference is cost; polyester is significantly less expensive to produce than silk, making the fabric more accessible. In terms of care, Satin Poly Pongee is far more forgiving. It is machine washable, dries quickly, and is highly wrinkle-resistant, whereas silk often requires dry cleaning and is prone to wrinkling. Durability is another key advantage; polyester fibers are much stronger than silk filaments, making Satin Poly Pongee more resistant to tears and damage from sunlight or perspiration. However, it is important to note that silk boasts superior breathability and a unique, natural hand-feel that polyester struggles to replicate perfectly.

The following table outlines the key differences:

| Feature | Satin Poly Pongee | Natural Silk Satin |

|---|---|---|

| Cost | Low to Moderate | High |

| Durability & Strength | Very High | Moderate (delicate) |

| Care & Maintenance | Easy, machine washable | Difficult, often dry clean only |

| Breathability | Moderate | High |

| Moisture Absorption | Low | High |

| Environmental Impact | Petroleum-based | Natural, but resource-intensive |

Why it Outperforms Standard Polyester

Compared to standard plain-weave polyester, Satin Poly Pongee offers enhanced aesthetic appeal. The satin weave gives it a luxurious shine and a smoother hand-feel, making it suitable for applications where appearance matters. The tighter weave also improves its wind and water resistance. While both share the core benefits of polyester (strength, easy care), Satin Poly Pongee elevates the material to a more premium category.

How to Identify and Select High-Quality Satin Poly Pongee

Not all Satin Poly Pongee is created equal. The market offers varying grades, and knowing how to discern quality is essential for making an informed purchase decision. This is especially true for those looking for high-quality satin poly pongee fabric by the yard, where material consistency is paramount.

Critical Indicators of Fabric Quality

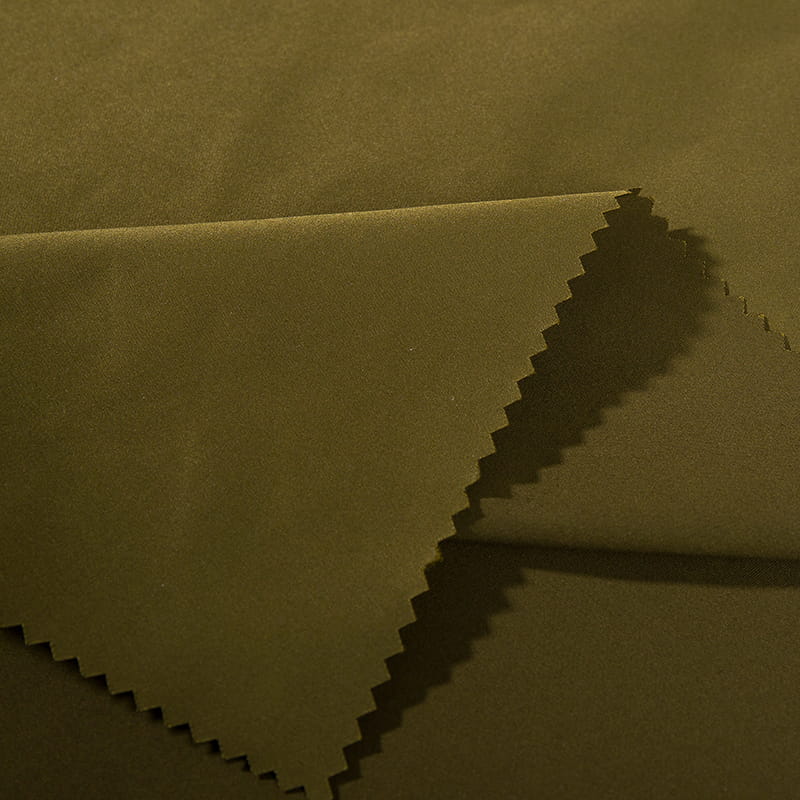

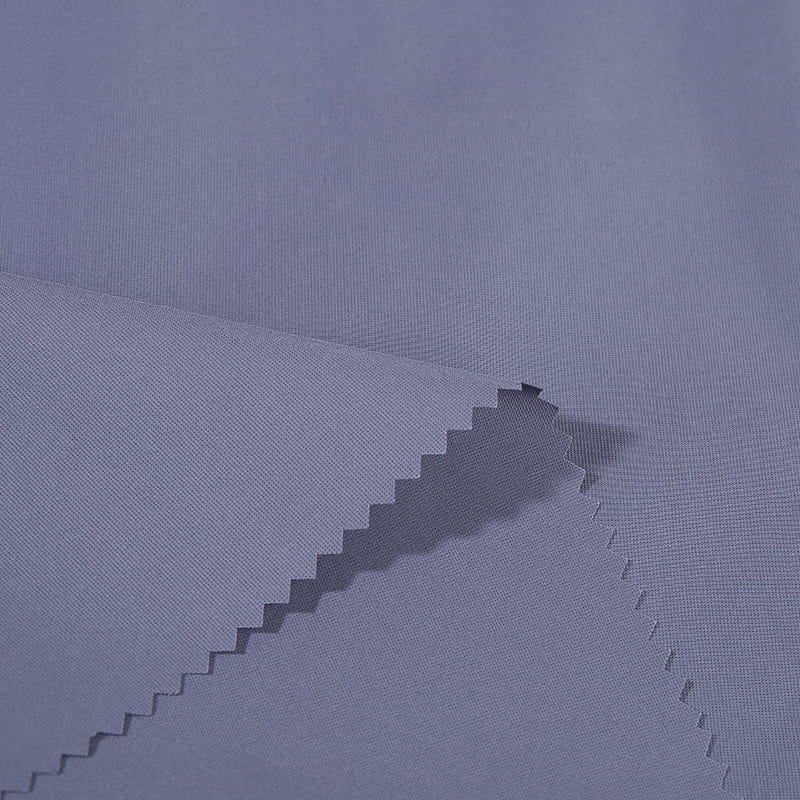

Several tactile and visual cues can help you identify superior quality material. First, examine the lustre: a high-quality piece will have a consistent, deep sheen across its entire surface, not a plastic-like, overly shiny glare. Second, feel the fabric. It should be smooth and soft, with no rough patches or snags. Drape a piece over your hand; it should fall in soft, fluid folds, not stiffly. Third, check the weave density. Hold the fabric up to the light; a tighter weave (where less light passes through) indicates better quality and improved durability and water resistance. Finally, look at the edges. The selvage (the finished edge of the fabric) should be even and straight, a sign of good manufacturing standards.

Understanding Weight and Thread Count

Two objective metrics are crucial for selection: fabric weight and thread count. Weight is typically measured in grams per square meter (GSM) or ounces per square yard (oz/yd²). For example, lightweight satin poly pongee 40D refers to a specific denier (D), which is a unit of measurement for the linear mass density of fibers. A 40D fabric is very light and fluid, ideal for delicate apparel and linings. Heavier weights, like 75D or 120D, offer more substance and durability for outerwear or home decor. Thread count, the number of threads per square inch, is equally important. A higher thread count generally signifies a tighter, smoother, and more durable fabric. For instance, a satin poly pongee with high thread count for durability will feel substantial and resist tearing far better than a low-count alternative.

Caring for Your Satin Poly Pongee Products

Proper maintenance is key to preserving the beautiful appearance and functional properties of Satin Poly Pongee items over their lifespan. While it is an easy-care fabric, following a few simple guidelines will ensure longevity.

Best Practices for Washing and Drying

Always begin by checking the care label on the finished product for any specific instructions. Generally, machine washing is acceptable on a gentle cycle with cold or warm water. Use a mild detergent and avoid bleach or harsh chemicals, as these can degrade the polyester fibers and dull the fabric's shine. To prevent snagging, turn the item inside out before washing and avoid washing it with heavy items or those with sharp zippers and hooks. When drying, tumble dry on a low heat setting or, even better, air dry. High heat can melt or damage synthetic fibers. If ironing is necessary, use a low heat setting and never iron directly on the shiny right side of the fabric; instead, iron on the reverse side or use a pressing cloth.

Long-Term Storage and Maintenance Tips

For long-term storage, ensure items are clean and completely dry to prevent mildew growth. Fold them neatly and store them in a cool, dry place away from direct sunlight, which can cause gradual fading. Avoid using wire hangers for heavy items like coats, as they can distort the shape of the shoulders over time. Instead, use padded hangers for garments that must be hung. For those seeking wrinkle-resistant satin poly pongee material, you are in luck, as this is one of its innate properties. However, if creases do occur from prolonged storage, hanging the garment in a steamy bathroom can often release the wrinkles without needing an iron.

The Future and Sustainability of Satin Poly Pongee

As the textile industry evolves, so does the production and perception of materials like Satin Poly Pongee. The future of this fabric is likely to be shaped by innovation and a growing emphasis on environmental responsibility.

Innovations in Production and Texture

Manufacturers are continuously developing new techniques to enhance the functionality and feel of the fabric. This includes advanced dyeing processes for more vibrant and colorfast results, as well as finishing treatments to improve water resistance without relying on harmful PFCs. There is also ongoing development in creating textures that mimic natural fabrics more closely, offering consumers more variety. The search for the perfect breathable satin poly pongee fabric is a key area of focus. This involves engineering the weave or incorporating moisture-wicking treatments to improve the fabric's performance in apparel, making it more comfortable for extended wear in various climates.

Environmental Considerations and Recycled Polyester

The primary environmental concern with Satin Poly Pongee is its basis in polyester, a polymer derived from petroleum. The production process is energy-intensive and contributes to plastic pollution, especially through microfibers shed during washing. However, the industry is responding with the increased adoption of recycled polyester (rPET). rPET is made from post-consumer plastic bottles, diverting waste from landfills and reducing the reliance on virgin petroleum. Fabrics made from recycled polyester possess the same performance qualities as virgin polyester. Choosing Satin Poly Pongee made from recycled content is a significant step towards a more sustainable textile choice, blending the fabric's desirable properties with a reduced environmental footprint.

English

English русский

русский عربى

عربى