Exploring the Secrets of Polyester Taffeta: The Weaving Code Behind Lightness and Density

2025-07-17

In the field of textile materials, polyester taffeta fabric stands out for its unique lightness and density, becoming the preferred material for many functional textiles. This characteristic is not accidental, but stems from its systematic design from raw material selection to weaving process. The following will deeply analyze how polyester taffeta fabric achieves the balance between lightness and density.

The unique advantages of ultra-fine denier polyester filaments

Polyester taffeta fabric uses polyester filaments as raw materials, and its core lies in the use of "ultra-fine denier" fibers. Denier is a unit for measuring the thickness of fibers, and the smaller the value, the finer the fiber. The ultra-fine denier polyester filaments used in polyester taffeta have extremely fine monofilament diameters, which greatly increases the number of fibers of the same weight. This finer fiber not only gives the fabric a light texture, but also lays the foundation for subsequent high-density weaving. The surface of ultra-fine denier fibers is smooth, and the contact area between them is large. After high-density interweaving, they can fit closely to form a uniform and dense fabric structure, which reduces the weight of the fabric while improving the overall strength and wear resistance.

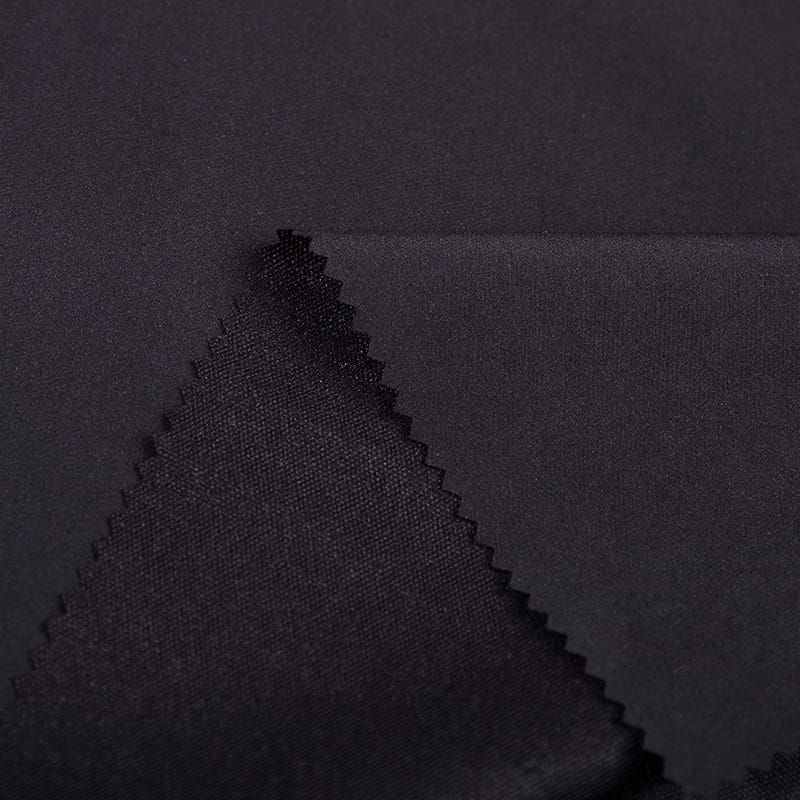

Key process of structural densification

The weaving of polyester taffeta adopts high warp density and high weft density interweaving, which is the core process to achieve fabric density. During the weaving process, the warp yarn and the weft yarn are interwoven with each other at a density far exceeding that of ordinary fabrics to form a tight grid structure. This high-density interweaving method is like building a fine protective net, which greatly reduces the pores on the surface of the fabric. The fine structure can not only effectively block wind and rain, but also prevent the surface of the fabric from pilling and enhance durability. High-density interweaving makes the surface of the fabric smooth and flat, improves the visual and tactile texture, and meets the needs of different application scenarios for appearance and feel.

Functional upgrade brought by lightness and density

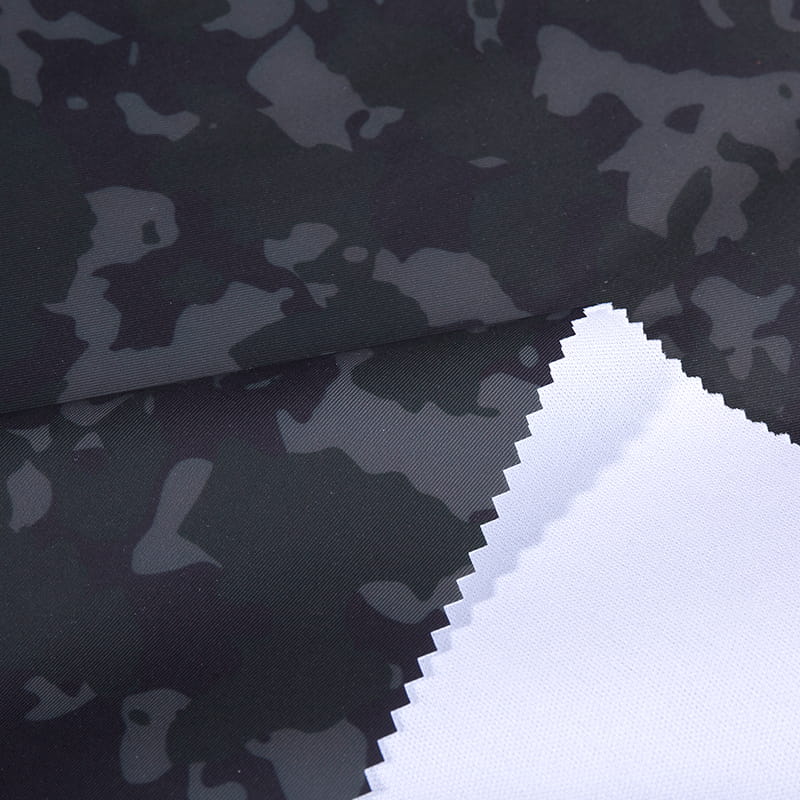

Polyester taffeta fabric achieves the synergy of lightness and density through the combination of raw materials and processes, thereby bringing a series of functional improvements. The light texture gives the fabric good flexibility and drape. It fits the body curve when worn and allows for easy movement, making it suitable for all kinds of clothing. The dense structure gives the fabric windproof, waterproof and impermeable properties, and can form an effective barrier even in the face of slight wind and rain. The fabric also maintains good breathability, and through the tiny pores between the fibers, air circulation is achieved to avoid wearing stuffy clothes. This balance of performance makes polyester taffeta fabric show strong applicability in outdoor clothing, luggage and outdoor equipment.

Continuous exploration of performance optimization

In order to further improve the performance of polyester taffeta fabric, the textile industry continues to explore process innovation. In the weaving process, the loom equipment and process parameters are improved, the weaving accuracy and efficiency are improved, and the warp and weft yarns are arranged more evenly and tightly; in the subsequent processing process, the waterproof and anti-fouling functions of the fabric are further enhanced through coating, calendering and other processing methods, while improving the feel and color of the fabric. The application of these innovative processes, while maintaining the core characteristics of polyester taffeta being light, thin and dense, expands its application boundaries to meet the needs of more market segments. From raw material selection to weaving process, and then to performance optimization and process innovation, polyester taffeta fabric achieves a balance between lightness and density through a series of careful designs and technological breakthroughs.

English

English русский

русский عربى

عربى