The Comprehensive Guide to stretch fabric

2025-11-11

What is stretch fabric and why it matters

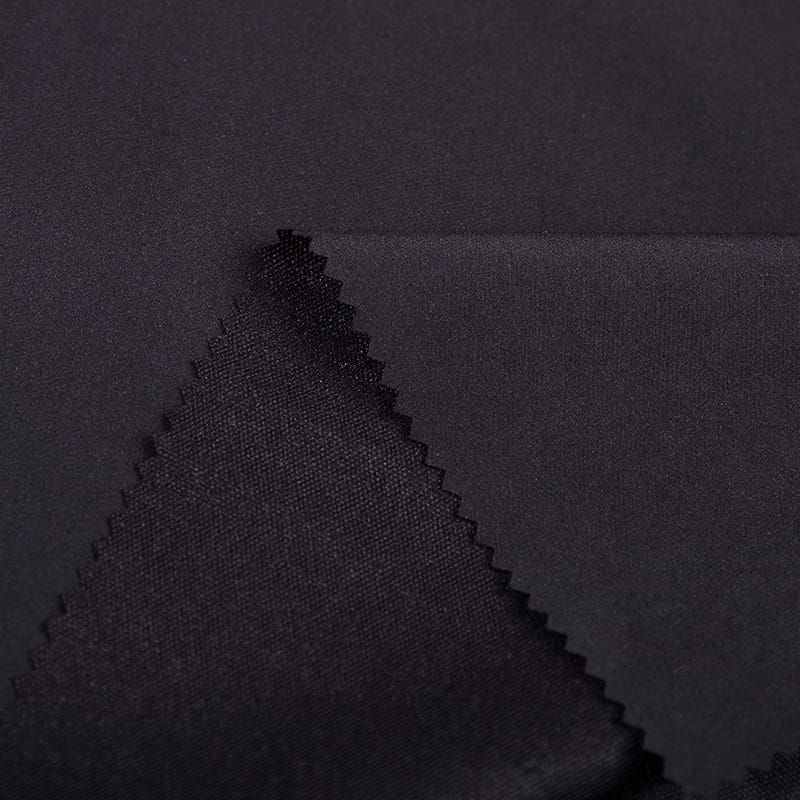

Definition and key characteristics

- Stretch fabric refers to textiles engineered to expand under tension and recover to their original shape — they are built with elastic fibres or specific knit/weave constructions. :

- These fabrics provide freedom of movement, greater comfort, and often improved shape retention and durability compared to non-stretch fabrics.

2-way vs 4-way stretch comparison

When selecting stretch fabric it is important to compare the stretch direction and recovery behaviour. The table below summarises the key differences:

| Stretch Type | Direction of Stretch | Typical Uses |

| 2-way stretch | Usually horizontal (selvage to selvage) | Fitted shirts, casual wear |

| 4-way stretch | Both horizontal and vertical | Activewear, outdoor gear, high-movement garments |

As you can see, a 4-way stretch fabric provides more freedom of movement than a 2-way stretch, while a 2-way stretch offers more stability but less elasticity.

5 Common Long-Tail Applications of stretch fabric

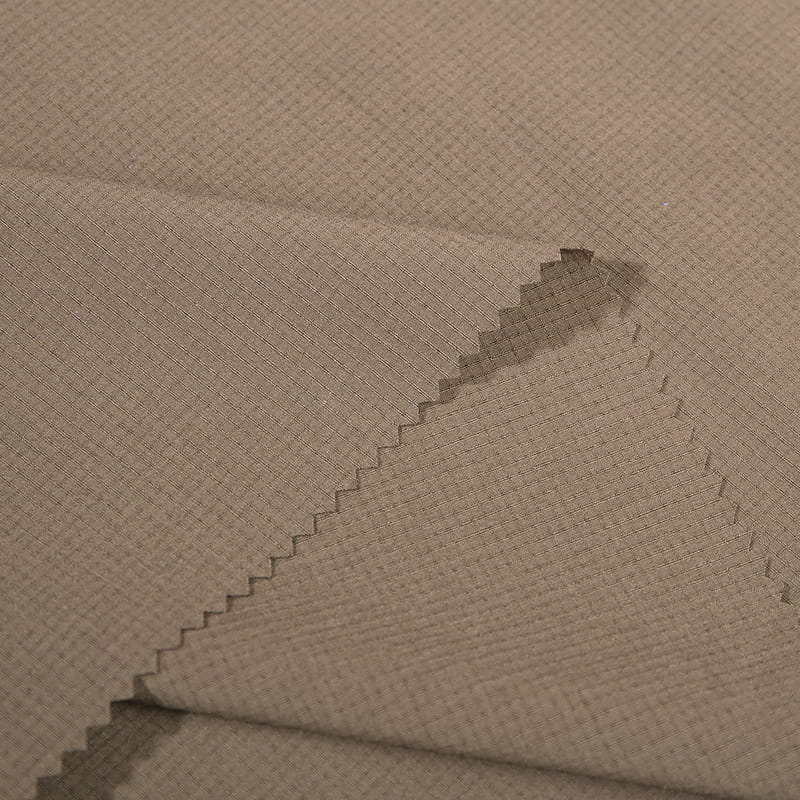

Use in outdoor jackets — stretch fabric for outdoor jackets

- Outdoor jackets require fabrics that combine mobility, weather resistance and durability.

- Our company, as a family-owned plant operating for over 20 years in China, specialises in the production of polyester nylon fabrics and linings for outdoor functional clothing lines, which makes us well-positioned to supply premium stretch fabrics for this application.

- By using engineered stretch blends, consumers get comfort without compromising structural integrity.

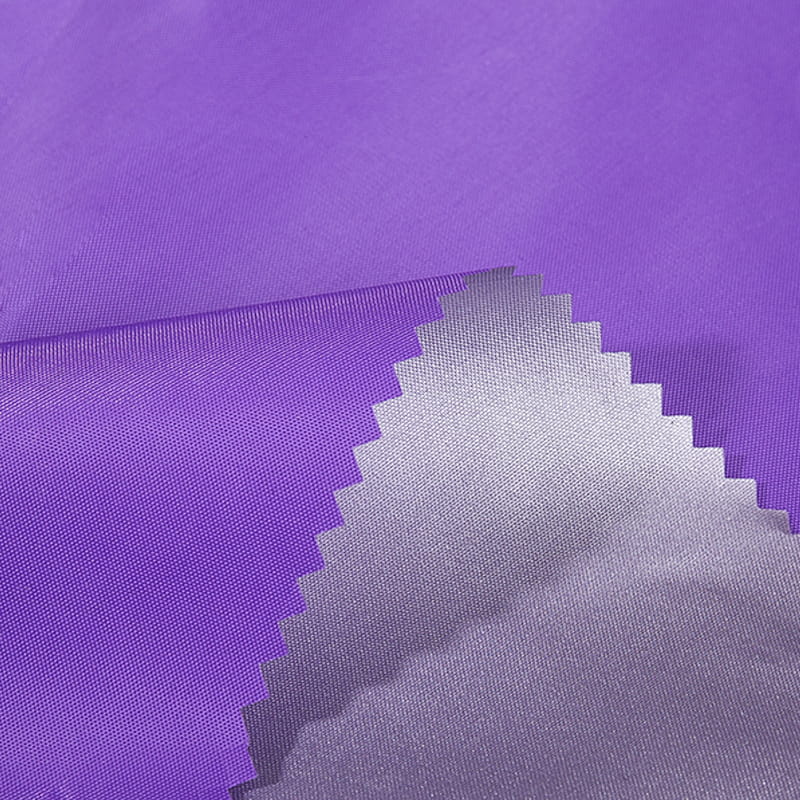

Use as lining in women’s apparel — stretch fabric lining for women’s apparel

- Women’s apparel often uses linings to improve drape, comfort and fit. Incorporating stretch into the lining fabric enhances wearer comfort.

- Our mills with 300 water jet looms and 100 matching twisters allow fast production of custom samples, enabling tailor-made stretch linings for women’s silk or jacquard lines.

Use in luggage fabrics — high durability stretch fabric for luggage

- Luggage fabrics must resist abrasion, tension and repeated use; introducing stretch elements can help shape retention and shock absorption.

- Stretch fabrics designed for luggage differ from apparel fabrics in durability metrics and finishing treatments — a direct comparison is shown below.

| Feature | Apparel Stretch Fabric | High Durability Stretch Fabric for Luggage |

| Elastane content (%) | Typically 3-7% | Lower elastic fibre content, more emphasis on nylon/polyester base |

| Abrasion resistance | Moderate | High |

| Recovery after stretch | Good, suitable for body movement | Excellent, to maintain shape under load |

This demonstrates how the application context shifts the fabric design, even though both are based on the core concept of stretch fabric.

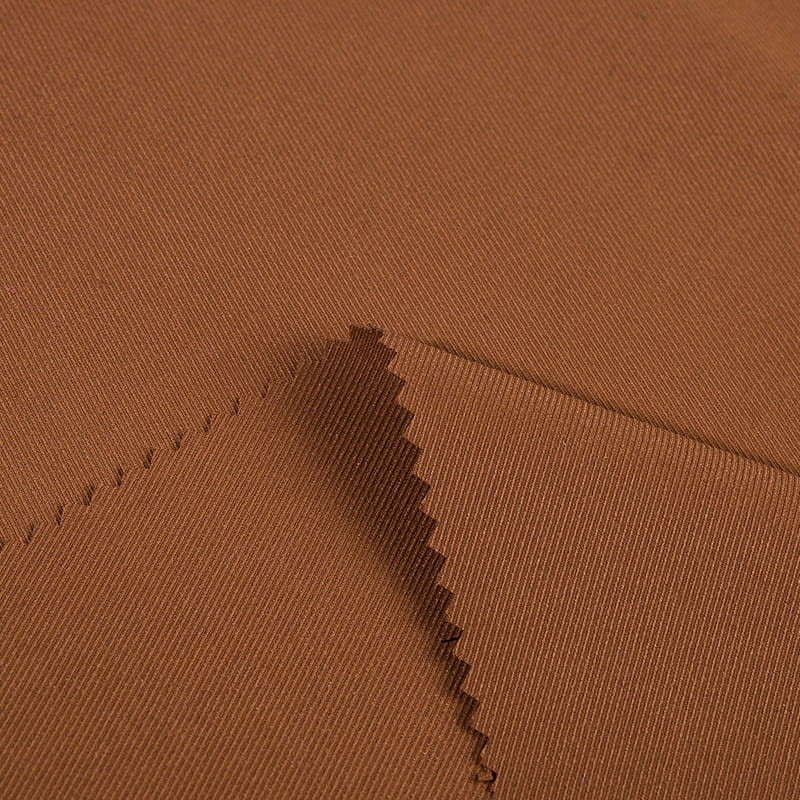

Custom production services from China — custom stretch fabric production China

- For brands or OEMs seeking tailored solutions, custom stretch fabric is a key service: colour, weight, composition, finishing can all be customised.

- Our company accepts custom samples from foreign customers and thanks to our 300 self-owned water jet looms and 100 twisters, we can deliver cost-effective products under quality assurance and with rapid delivery.

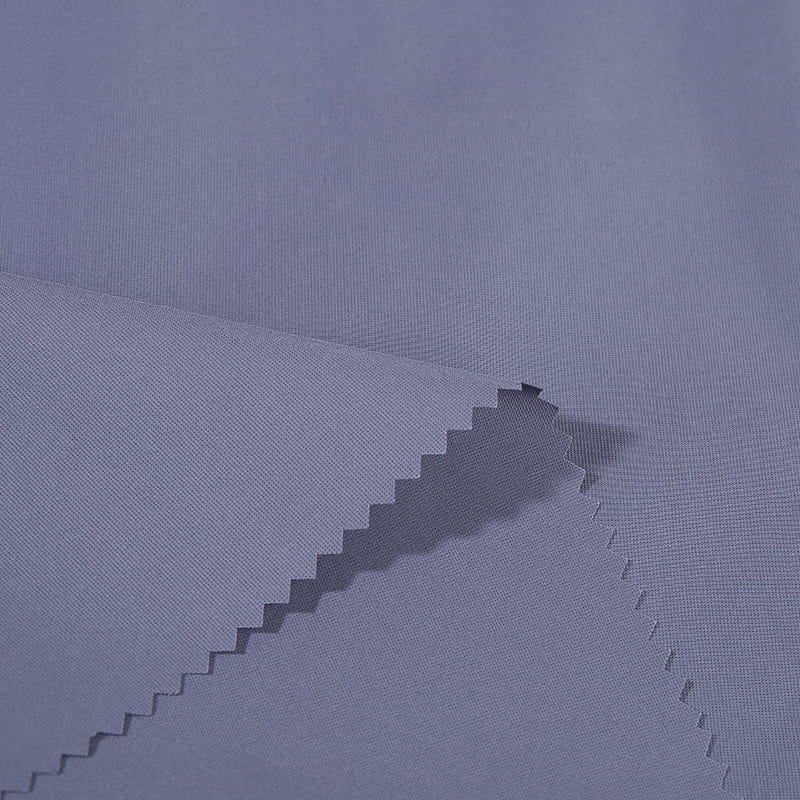

Polyester/nylon blends for functional clothing — polyester nylon stretch fabric for functional clothing

- Functional clothing (e.g., outdoor gear, technical apparel) demands fabrics that combine strength, stretch, moisture-management and quick delivery.

- Using polyester/nylon stretch fabrics allows us to balance performance and cost: our long experience in the textile business and finishing process ensures these blends meet demanding requirements.

How to Choose and Produce Quality stretch fabric

Material composition and weave/knit types

- Look at the fibre blend (e.g., polyester/nylon + elastane) and construction (woven vs knit). Some stretch arises from knit loops rather than added elastic fibres.

- For wovens used in functional/outdoor fabrics, water-jet looms are often used for speed and consistency — which aligns with our production capability.

Key performance metrics and tests

- Measure stretch percentage and recovery: e.g., horizontal vs vertical stretch.

- Test abrasion resistance, shape retention, shrinkage, and finishing durability.

Production & finishing – our company’s advantage

- As a family-owned plant with over 20 years of experience, we focus on polyester nylon fabrics and linings for outdoor functional clothing lines, women’s silk lines, jacquard luggage fabrics, and outdoor goods.

- With 300 water jet looms and 100 matching twisters, the quantity of our equipment ensures rapid delivery and cost-effective production under quality assurance.

- We also accept custom samples from foreign customers — making us a reliable partner for custom stretch fabric production.

Care, Finishing and Sustainability of stretch fabric

Care instructions for longevity

- Avoid over-stretching the fabric when handling or cutting in production, as this can damage elastic fibres.

- Use appropriate finishing processes: proper washing, low tumble drying, avoid high heat to maintain elasticity and shape.

Sustainability considerations in stretch fabric

- Stretch fabrics often include synthetic elastic fibres (e.g., spandex/elastane) which may complicate recycling efforts.

- Selecting blends thoughtfully and working with fabric producers who have control over finishing and quality (like us) helps optimise material usage and reduce waste.

Conclusion & Why Partner with Us for stretch fabric

In summary, understanding the properties, applications and production considerations of stretch fabric is key to selecting the right textile for your garment or product line. Whether you are looking for stretch fabric for outdoor jackets, stretch fabric lining for women’s apparel, high durability stretch fabric for luggage, custom stretch fabric production China or polyester nylon stretch fabric for functional clothing, our company is well positioned to deliver.

With decades of experience, substantial production capability (300 water jet looms and 100 twisters), openness to custom samples from foreign customers, and deep expertise in finishing processes, we provide cost-effective and quality-assured products with rapid delivery. Welcome to our factory in China.

FAQ

- Q1: What does “4-way stretch” mean in a fabric?

A1: “4-way stretch” means the fabric can stretch both horizontally and vertically (crosswise and lengthwise), offering greater mobility than a 2-way stretch fabric. - Q2: Can a woven fabric have stretch?

A2: Yes — some fabrics achieve stretch via mechanical weaves rather than elastane fibres, though knit fabrics are more common. - Q3: What should I look for when sourcing stretch fabric for outdoor gear?

A3: Key factors include fibre blend (e.g., polyester/nylon with elastane), stretch direction (4-way may be preferred), abrasion resistance, finishing for outdoor conditions, and production capacity/lead time. As outlined above, our facility with large loom capacity and custom sample acceptance supports this. - Q4: How does adding elastane affect durability and recyclability?

A4: While elastane (spandex) provides elasticity and recovery, it complicates recycling because even a small percentage may render the fabric incompatible with mechanical recycling. - Q5: Why should I choose a manufacturer with in-house loom capacity like yours?

A5: Having 300 self-owned water-jet looms and 100 matching twisters allows larger output, better control of quality and faster delivery. This capacity supports cost-effectiveness and customisation for stretch fabric production tailored to your needs.

English

English русский

русский عربى

عربى