The Ultimate Guide to Satin Poly Pongee: Properties, Uses, and Selection

2025-09-16

Understanding Satin Poly Pongee Fabric

Satin Poly Pongee is a distinctive and versatile fabric that has carved a significant niche in the textile industry. It is a blend that combines the best properties of its constituent materials, resulting in a textile that is both functional and aesthetically pleasing. To truly appreciate its value, one must understand its composition and the unique characteristics that set it apart from other materials.

What is Satin Poly Pongee?

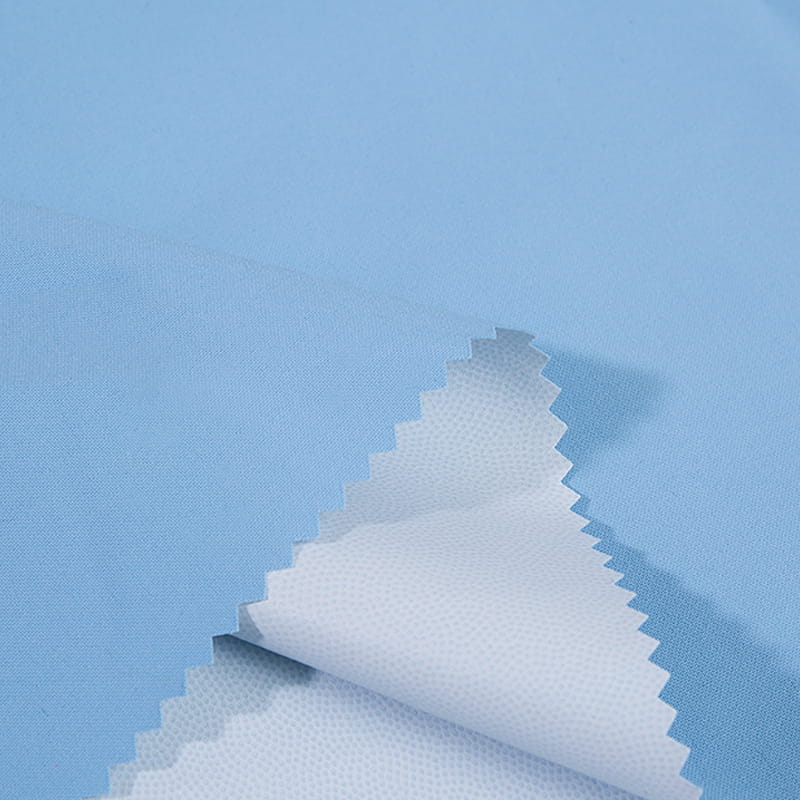

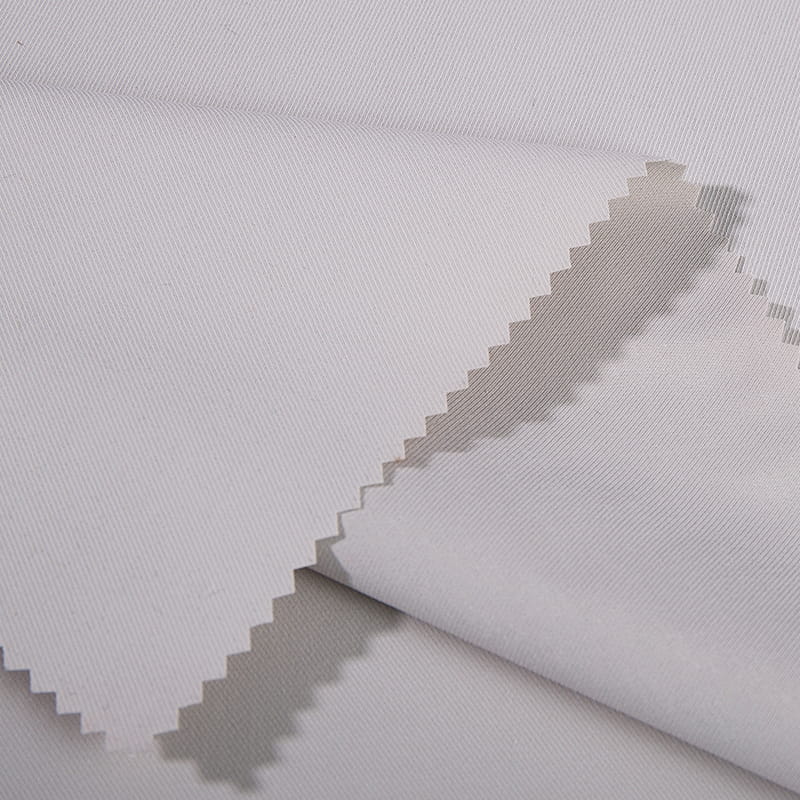

The term "Pongee" traditionally refers to a plain-weave fabric, originally made from wild silk, known for its soft texture and natural tan color. However, modern Pongee is predominantly made from polyester filaments. The "Satin" in its name denotes the weave structure used—a satin weave. This weave is characterized by a high number of interlacings where the warp yarns float over multiple weft yarns, creating a smooth, lustrous surface on one side and a duller back. The "Poly" indicates that the primary fiber used is polyester. Therefore, Satin Poly Pongee is a fabric constructed using a satin weave with polyester yarns, inheriting the durable and easy-care properties of polyester and the luxurious, glossy finish of a satin weave.

Key Characteristics and Benefits

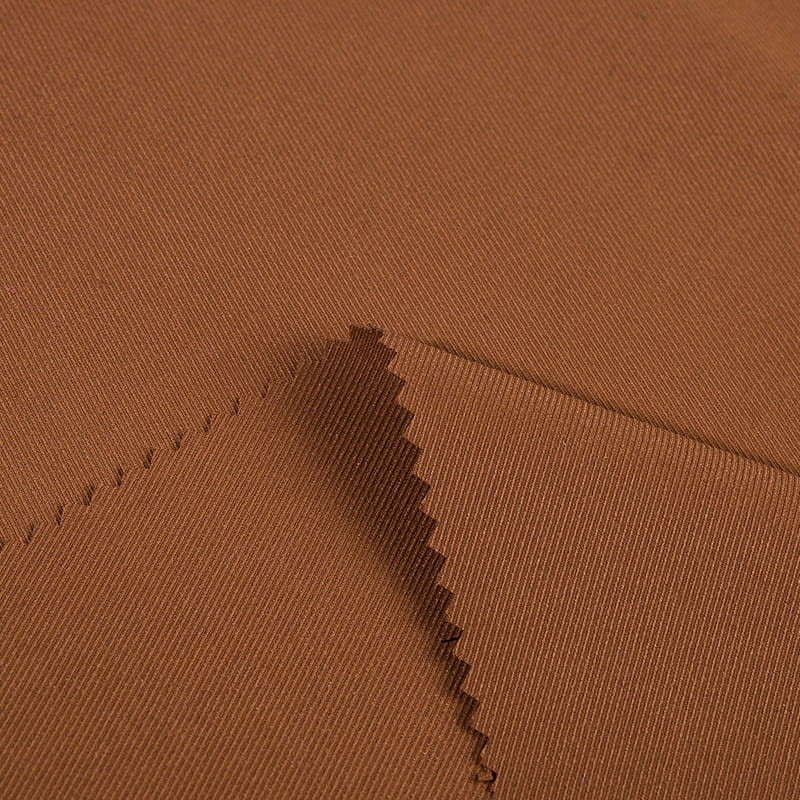

Satin Poly Pongee is celebrated for a host of desirable properties that make it suitable for a wide range of applications. Its defining feature is its sublime smoothness and noticeable sheen, which impart a high-end, luxurious feel often associated with more expensive materials. Despite this luxurious appearance, it is remarkably durable and resistant to abrasion, thanks to the inherent strength of polyester fibers. This fabric is also lightweight and possesses excellent drape, allowing it to flow elegantly, which is a critical factor in apparel and decorative uses. Furthermore, it is relatively easy to care for; it is wrinkle-resistant and dries quickly. Its tightly woven structure, often enhanced with coatings, can offer a degree of water and wind resistance, making it a practical choice for outdoor gear like umbrellas and light jackets. When searching for a waterproof satin poly pongee fabric, one is specifically looking for a version that has been treated with a polyurethane or other coating to enhance its resistance to water penetration, making it ideal for protective outerwear.

Top Applications and Uses of Satin Poly Pongee

The unique combination of aesthetics and functionality makes Satin Poly Pongee a highly sought-after material across various sectors. Its applications range from high-fashion runways to practical everyday items, demonstrating its incredible versatility.

Fashion and Apparel

In the world of fashion, Satin Poly Pongee is a favorite for garments that require a fluid drape and a touch of elegance. Designers frequently utilize it for creating luxurious evening wear, including dresses, blouses, and skirts that shimmer under lights. Its smooth surface is also ideal for delicate lingerie and nightwear, providing comfort against the skin. Beyond formal wear, its durability makes it suitable for fashion-forward outerwear, such as lightweight windbreakers and stylish raincoats, especially when a waterproof finish is applied. The fabric's ability to hold vibrant dyes results in rich, deep colors that are long-lasting, adding to its appeal in the apparel industry.

Home Décor and Furnishings

The decorative potential of Satin Poly Pongee is extensively tapped in home furnishings. Its subtle sheen and elegant drape make it perfect for creating statement window treatments like curtains and drapes that allow light to filter through beautifully. It is also used in upholstery for accent furniture, pillows, and throws, adding a textural contrast and a hint of sophistication to living spaces. Additionally, its resistance to wear and ease of cleaning are practical benefits for home decor items that see frequent use.

Technical and Industrial Uses

Beyond its aesthetic applications, Satin Poly Pongee serves important functional roles. Its most classic technical use is in the manufacturing of umbrellas. The fabric's tight weave, potential water resistance, and ability to be tightly folded without damage make it the perfect material for this purpose. It is also used in the production of lightweight luggage, protective covers for equipment, and even in certain types of flags and banners where a sleek appearance is desired. For those in need of a material for protective covers, finding a satin poly pongee fabric for umbrellas is a common requirement, as this specific application demands a precise balance of sheen, weight, and water repellency.

How to Choose the Right Satin Poly Pongee

Selecting the appropriate grade and type of Satin Poly Pongee is crucial for ensuring it performs as expected in its final application. Several factors must be considered to make an informed decision.

Weight and Denier

The weight of the fabric, often measured in grams per square meter (GSM) or denier (the mass in grams of 9,000 meters of yarn), is a primary indicator of its thickness and durability. Lower denier fabrics (e.g., 30D-75D) are very lightweight, sheer, and delicate, ideal for fine linings or delicate apparel. Medium weights (e.g., 90D-120D) offer a good balance of strength and drape, suitable for a wide range of clothing and home decor. Heavyweight Satin Poly Pongee (150D and above) is much more robust and is typically used for applications requiring greater durability and structure, like bags or heavy-duty umbrellas.

Coatings and Finishes

A fundamental choice is between coated and uncoated varieties. Uncoated Satin Poly Pongee offers its natural sheen and drape but has minimal water resistance. Coated versions, on the other hand, are treated with substances like polyurethane (PU) or polyvinyl chloride (PVC) to enhance their functionality. A PU coating provides a good level of water resistance while maintaining the fabric's flexibility and breathability. A PVC coating offers heavier, more impermeable waterproofing but can make the fabric stiffer. Other finishes include calendering (to enhance sheen), dyeing, and printing processes. For instance, a wholesale satin poly pongee by the yard might be available in both coated and uncoated options, allowing bulk buyers to select the exact specification for their manufacturing needs.

Satin Poly Pongee vs. Other Common Fabrics

To fully understand the value proposition of Satin Poly Pongee, it is helpful to compare it with other fabrics that might be considered for similar applications. The key differentiators often lie in texture, durability, care, and cost.

Comparison with Pure Satin and Taffeta

Pure Satin (often made from silk or acetate) is renowned for its unparalleled luxurious feel and high sheen. However, it is delicate, expensive, and requires meticulous care. Satin Poly Pongee, by contrast, offers a similar visual appeal with significantly greater durability, wrinkle resistance, and affordability, though it may not match the exact hand-feel of premium silk satin. Taffeta, another crisp, plain-weave fabric, shares some uses with Pongee (e.g., umbrellas, linings). However, Taffeta has a stiffer hand and a characteristic rustle, while Satin Poly Pongee is softer, smoother, and has a luminous satin finish rather than a muted sheen. This makes breathable satin poly pongee lining material a preferred choice for garment linings where comfort and a reduced friction interface are paramount.

The following table summarizes the key differences:

| Feature | Satin Poly Pongee | Pure Silk Satin | Polyester Taffeta |

|---|---|---|---|

| Primary Fiber | Polyester | Silk | Polyester |

| Weave | Satin | Satin | Plain |

| Sheen | High, lustrous | Very High, luxurious | Medium, muted |

| Durability | High | Low | High |

| Care | Easy, machine washable | Dry clean or hand wash | Easy, machine washable |

| Cost | Low to Moderate | High | Low |

| Typical Use | Apparel, linings, umbrellas | High-end eveningwear, lingerie | Umbrellas, bags, linings |

Caring for Your Satin Poly Pongee Products

Proper maintenance is key to preserving the beauty and extending the lifespan of products made from Satin Poly Pongee. While it is a low-maintenance fabric, following some basic guidelines will ensure it remains in pristine condition.

Washing and Drying Guidelines

Always check the care label first, as coatings or specific constructions may alter care requirements. Generally, machine washing on a gentle cycle with cold water is safe. Use a mild detergent and avoid bleach or harsh chemicals that can degrade the fibers or affect the color. To prevent snagging, turn the item inside out before washing. It is best to wash it separately or with similar colors and fabrics. For drying, tumble dry on a low heat setting or, even better, allow it to air dry. High heat can damage the fibers or melt any coatings, and it can also set wrinkles, although the fabric is naturally wrinkle-resistant.

Ironing and Storage Tips

Satin Poly Pongee usually emerges from the wash with very few wrinkles. If ironing is necessary, use a low heat setting and never place the iron directly on the fabric's right side. Instead, turn the garment inside out or use a pressing cloth to protect the delicate satin surface from scorching and shine marks. For storage, fold the items neatly and store them in a cool, dry place away from direct sunlight, which can cause fading over time. Avoid using wire hangers for heavy items, as they can cause stretching; instead, use padded hangers for garments to help them retain their shape. This is especially important for a lightweight satin poly pongee for clothing, as its delicate structure can be more susceptible to deformation under stress.

Finding a Reliable Source for Satin Poly Pongee

Whether you are a designer, manufacturer, or a passionate DIY crafter, sourcing high-quality Satin Poly Pongee is fundamental to the success of your project. Knowing what to look for in a supplier can save time and ensure consistency.

Key Supplier Considerations

When evaluating potential suppliers, consider their reputation and experience in the textile market. A supplier with a long history is often more reliable. Review their product specifications carefully; a good supplier will provide detailed information on denier, GSM, width, coating type (if any), and composition. Requesting swatches is a non-negotiable step. This allows you to physically assess the hand-feel, weight, color accuracy, and sheen of the fabric before making a bulk purchase. Inquire about their minimum order quantities (MOQs) and whether they offer custom dyeing, coating, or printing services to meet your specific requirements. For larger projects, finding a supplier that offers custom printed satin poly pongee fabric can be a significant advantage, allowing for unique designs and branding.

Understanding Quality Indicators

High-quality Satin Poly Pongee will have a consistent weave with no visible flaws or slubs. The color should be even and vibrant, with no bleeding or fading. The selvedge (the finished edge of the fabric) should be straight and clean, not curled or frayed. If the fabric is coated, the coating should be applied evenly without any sticky spots or blotches. The fabric should feel smooth and strong, not flimsy or prone to tearing. For those seeking the best value, a wholesale satin poly pongee by the yard from a reputable supplier ensures you get a consistent, high-quality product at a competitive price point, making it ideal for production runs.

English

English русский

русский عربى

عربى