The Ultimate Guardian: PVC/PU Coated Oxford Fabric for Extreme Waterproof & Abrasion-Resistant Gear

2025-09-24

In the world of technical textiles, few materials offer the versatile performance of PVC PU Coating Oxford fabric. This engineered fabric is the backbone of countless products demanding durability, weather resistance, and reliability. But what exactly makes it the go-to choice for manufacturers and designers? This in-depth guide explores the science, applications, and key differences of this powerhouse material, helping you understand why it's the undisputed champion for creating extreme waterproof and abrasion-resistant gear. We'll delve into its composition, the distinct advantages of PU and PVC coatings, and guide you through selecting the right type for your project.

What is PVC/PU Coated Oxford Fabric? Deconstructing the Powerhouse

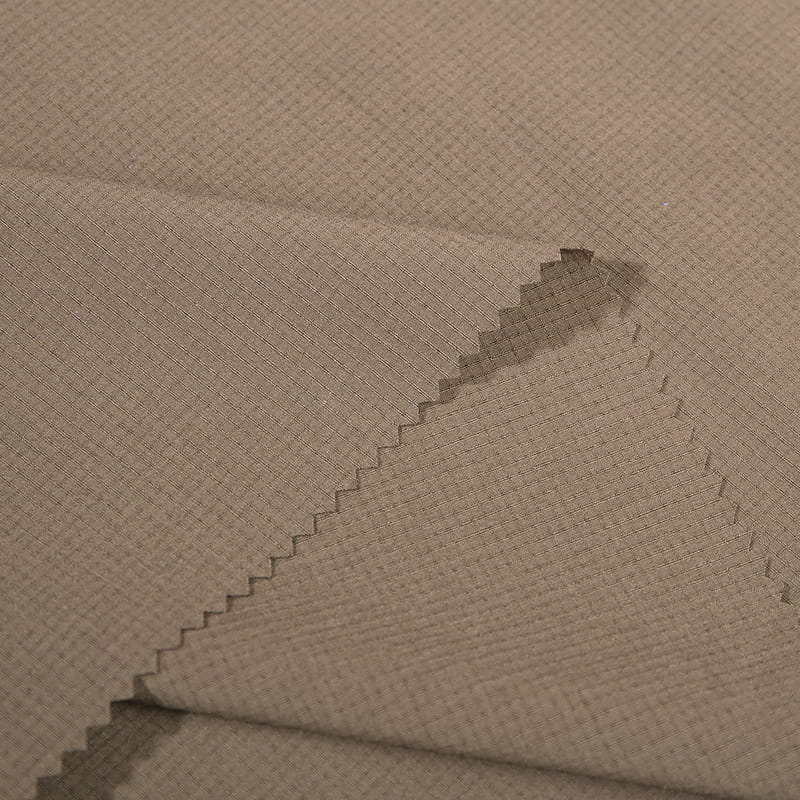

To truly appreciate its capabilities, one must understand its construction. PVC PU Coating Oxford fabric is not a single material but a sophisticated composite system. It starts with a base fabric woven from synthetic yarns, typically nylon or polyester, in a signature basketweave pattern that gives Oxford its distinctive texture and inherent strength. This base fabric is then transformed through a coating process where either Polyurethane (PU) or Polyvinyl Chloride (PVC) is applied to one or both sides. This coating is the critical component that imbues the fabric with its legendary protective properties. It acts as an impermeable shield, blocking water molecules, resisting abrasion from rough surfaces, and protecting against mildew and UV degradation. The combination of a tough woven base and a engineered polymer coating creates a synergistic effect, resulting in a material that is far more capable than the sum of its parts, ready to face harsh environments head-on.

- Base Fabric: Typically nylon or polyester yarns woven in a 2x1 or 2x2 basketweave pattern, providing a strong, flexible, and tear-resistant foundation.

- Coating Process: The polymer (PU or PVC) is applied as a liquid layer and then cured, forming a continuous, seamless film over the fabric threads.

- Functional Additives: The coatings can be formulated with additives to enhance performance, including UV inhibitors for sun resistance, fire retardants, and plasticizers for flexibility.

PU Coated Oxford Fabric: The Lightweight and Flexible Performer

PU coating Oxford fabric is renowned for its exceptional balance of performance, weight, and environmental resistance. The Polyurethane coating forms a microporous film that is inherently waterproof yet breathable, allowing water vapor from inside to escape while preventing liquid water from entering. This characteristic makes it an ideal choice for applications where condensation management is crucial, such as high-end tactical gear and outdoor apparel. PU coatings are typically lighter and softer than PVC, giving the finished fabric a more pliable hand feel and making it easier to pack and carry. It also exhibits superior resistance to cold temperatures, remaining flexible without cracking, and offers excellent resistance to oils, chemicals, and abrasion. For projects where premium performance, lighter weight, and a better aesthetic are priorities, PU coating is often the preferred selection.

- Key Advantage: Breathability for user comfort during high-exertion activities.

- Key Advantage: Lighter weight and softer hand feel, enhancing portability.

- Key Advantage: Excellent low-temperature flexibility and chemical resistance.

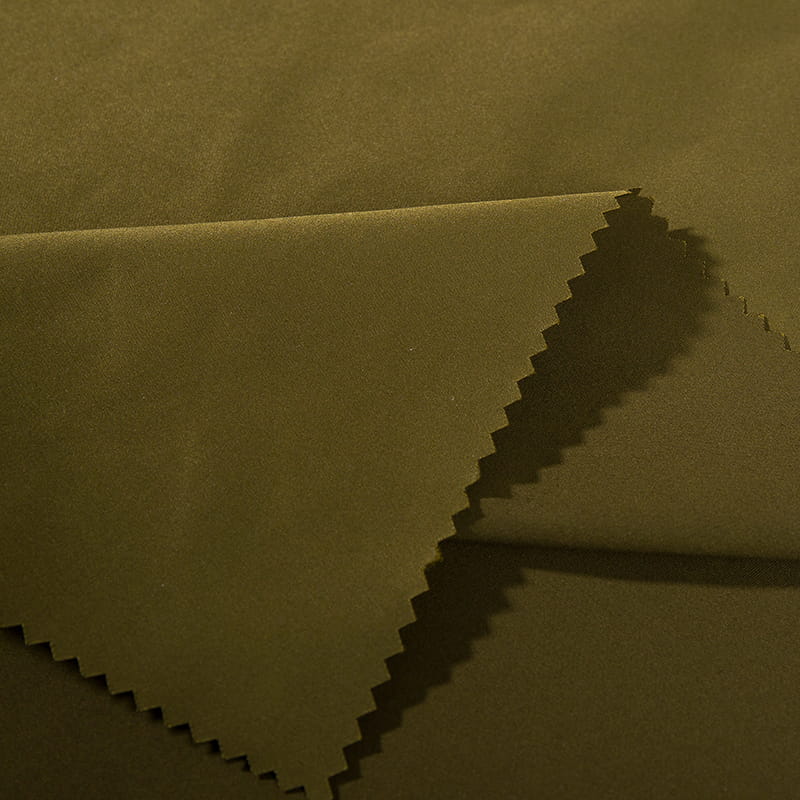

PVC Coated Oxford Fabric: The Durable and Economical Workhorse

When ultimate durability and cost-effectiveness are the primary drivers, PVC coating Oxford fabric stands out as the undisputed workhorse. Polyvinyl Chloride coating creates a thicker, completely impermeable barrier against water, making it 100% waterproof for the most demanding applications like heavy-duty tarps and industrial covers. The material is incredibly tough, offering outstanding resistance to abrasion, tearing, and punctures, which is why it's the standard for truck covers and equipment housings that face constant wear and tear. While generally stiffer and heavier than its PU counterpart, PVC coatings can be formulated to achieve varying degrees of flexibility. Its primary advantage lies in its robust physical properties and lower production cost, making it the perfect solution for heavy-duty, large-scale industrial and commercial uses where absolute waterproofing and maximum longevity are non-negotiable.

- Key Advantage: Superior abrasion and tear resistance for extreme-duty use.

- Key Advantage: 100% Waterproof impermeable barrier for complete protection.

- Key Advantage: High cost-effectiveness for large-scale or budget-conscious projects.

PU vs. PVC Coating: A Detailed Comparison Table

Choosing between PU and PVC coatings depends heavily on the specific requirements of your application. The following table breaks down their key characteristics to help you make an informed decision.

| Characteristic | PU Coated Oxford | PVC Coated Oxford |

| Waterproofness | Waterproof & Breathable | 100% Waterproof |

| Weight & Flexibility | Lighter, Softer, More Flexible | Heavier, Stiffer |

| Abrasion Resistance | Very Good | Excellent |

| Low-Temp Performance | Remains Flexible | Can Become Stiff |

| Chemical Resistance | Excellent | Good |

| Primary Application | Tents, High-End Bags, Apparel | Tarps, Truck Covers, Industrial Uses |

Top 5 Applications of Coated Oxford Fabric

The unique properties of PVC PU Coating Oxford fabric make it indispensable across a wide range of industries. Its adaptability allows it to be engineered for specific uses, from protecting valuable assets from the elements to providing shelter in remote locations. The material's reliability is the reason it's trusted by professionals in fields as diverse as logistics, construction, outdoor recreation, and disaster relief. By understanding these applications, one can better appreciate the material's impact on modern life and its critical role in creating products that are built to last. The following list highlights some of the most common and demanding uses for this versatile material.

- Outdoor Equipment and Protective Covers: This is a classic application, encompassing heavy-duty outdoor storage solutions like waterproof covers for machinery, woodpiles, and outdoor furniture. Its resilience against rain, UV rays, and physical abuse ensures long-term protection.

- Luggage and Protective Bags: The fabric is extensively used in protective luggage and cases for tools, musical instruments, and sensitive equipment. The coating guards against scratches, impacts, and moisture during transit, making it ideal for protective luggage and cases.

- Tents and Shelter Systems: From simple camping tents to complex military and disaster relief shelters, coated Oxford fabric provides the critical waterproof and structural layer. PU coatings are often preferred for breathability in longer-term habitation tents.

- Automotive and Transportation: Beyond car covers, it's used for truck tarps, side curtains, and interior linings. Its strength withstands wind buffeting and road debris, while its waterproofness protects cargo from the elements.

- Industrial and Workwear: The fabric is used in aprons, protective smocks, and workwear where resistance to oils, chemicals, and abrasion is required for worker safety.

How to Choose the Right Coated Oxford Fabric for Your Needs

Selecting the optimal PVC PU Coating Oxford fabric requires a careful evaluation of your project's specific demands. It's not merely about picking one over the other; it's about matching the material's properties to the environmental challenges and functional requirements of the final product. Key considerations include the intensity of weather exposure, the need for breathability versus absolute waterproofing, the physical stresses of abrasion and puncture, and overall budget constraints. For instance, a breathable PU fabric would be miserable for a stationary truck cover, just as a stiff PVC fabric would be overkill for a lightweight duffel bag. By systematically assessing factors like denier thickness, coating weight, and performance certifications, you can ensure you select a fabric that delivers reliable performance and represents the best value for your application.

- Assess the Environment: Will the product face constant rain (favoring PVC) or require user comfort through breathability (favoring PU)? Consider UV exposure and temperature ranges.

- Evaluate Physical Stress: Determine the level of abrasion, puncture, and tear resistance needed. Heavy-duty industrial applications lean toward PVC.

- Consider Weight and Flexibility: For portable items like bags or wearable gear, the lighter and more flexible nature of PU is a significant advantage.

- Understand Specifications: Look at technical data like hydrostatic head (HH) for waterproofness, abrasion cycles (Martindale test), and denier (e.g., 600D, 1000D) which indicates yarn thickness and fabric density.

- Budget and Longevity: Balance initial material cost against the expected lifespan of the product. PVC often offers a lower entry cost for high-durability items.

FAQ

What is the difference between 600D and 1000D Oxford fabric?

The "D" stands for Denier, which is a unit of measurement for the linear mass density of yarns. It indicates the thickness and, by extension, the durability of the base fabric before coating. A 600D Oxford fabric uses yarns that are thinner than those in a 1000D fabric. Consequently, 1000D Oxford fabric is generally heavier, thicker, and offers greater resistance to abrasion and tearing compared to 600D. Think of 600D as a robust all-rounder suitable for regular backpacks and gear, while 1000D is reserved for heavy-duty applications like tactical equipment, industrial covers, and cases that must withstand extreme abuse. The choice between them depends on the perfect balance between the strength required and the weight acceptable for the final product.

Is PU-coated Oxford fabric truly waterproof?

Yes, high-quality PU coating Oxford fabric is absolutely waterproof. Its waterproof capability is typically measured by a hydrostatic head (HH) test, expressed in millimeters (mm). A fabric with a rating of 1000mm HH can withstand the pressure of a 1000mm column of water before leakage occurs. Premium PU-coated fabrics often exceed 3000mm HH, qualifying them as highly waterproof for severe weather conditions. The key differentiator from PVC is that PU achieves this through a microporous membrane that blocks liquid water but allows water vapor (sweat) to pass through, a property known as breathability. So, while both are waterproof, PU offers the added benefit of moisture management for user comfort.

How do I clean and maintain my PVC-coated Oxford gear?

Proper maintenance extends the life of your PVC coating Oxford fabric products significantly. For routine cleaning, use a soft brush or sponge with a mild soap solution (like dish soap) and lukewarm water to gently scrub the surface. Avoid harsh detergents, abrasive cleaners, or solvents that can degrade the coating or cause discoloration. After cleaning, rinse thoroughly with clean water and allow it to air dry completely before folding or storing to prevent mildew. For stubborn stains, spot cleaning with a dedicated technical fabric cleaner is recommended. Periodically, treating the fabric with a UV protectant spray can help shield it from sun damage, which is a common cause of long-term degradation for materials left outdoors.

Which is more environmentally friendly: PU or PVC coating?

This is a complex question. Generally, Polyurethane (PU) is often considered to have a better environmental profile than traditional PVC. Standard PVC can contain chlorine and plasticizers like phthalates, which have raised health and environmental concerns. However, the industry has responded with bio-based PU coatings and phthalate-free PVC formulations. The most eco-friendly choice depends on the specific formulation. Look for manufacturers who provide information on Oeko-Tex certifications (ensuring no harmful substances) or who use recycled content in their polyester base yarns. Ultimately, the longevity of the product is a major factor in its sustainability; a highly durable cover that lasts for 10 years is more eco-friendly than a biodegradable one that needs replacing every year.

Can coated Oxford fabric be repaired if it gets torn?

Yes, both PVC and PU coated Oxford fabrics can be effectively repaired, which is a testament to their durability. For small punctures or tears, specialized repair tapes designed for vinyl or nylon fabrics work very well. Simply clean and dry the area thoroughly, cut a patch of tape larger than the damage, round the corners, and apply firm pressure. For more significant damage, sewing is an option, but it requires a heavy-duty needle and thread. It is crucial to then seal the stitch holes with a seam sealer (a liquid waterproofing compound) to restore the waterproof integrity of the fabric. Many manufacturers also offer professional repair services for their high-end products.

English

English русский

русский عربى

عربى