A breakthrough in the application of high-performance composite polyester fabrics in outdoor equipment.

2025-05-29

Technical characteristics and performance advantages

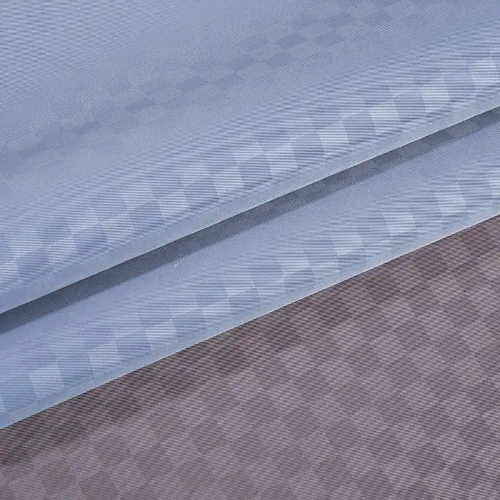

The latest generation of Combined Polyester Fabric achieves breakthrough performance improvements through multi-layer composite structures. The base layer uses ultrafine denier polyester filaments to give the fabric excellent tear resistance and wear resistance; the intermediate layer is composited with microporous membrane material to achieve excellent waterproof and breathable function; the surface layer has been specially treated and has UV resistance, anti-fouling and quick-drying characteristics. This composite structure allows the fabric to remain light (only 70% of the weight per unit area and the tensile strength is increased by 40%, and the breathability index reaches 15,000g/m²/24h, fully meeting the demand for rigorous outdoor activities such as alpine climbing and polar adventure.

Innovative application of outdoor equipment

In the field of windbreaker clothing, the products of Combined Polyester Fabric achieve true all-weather protection. The three-layer composite structure effectively blocks the invasion of wind and rain, and at the same time, it quickly discharges sweat on the body surface through directional wet guide technology to keep the inside dry. In terms of mountaineering backpack applications, the new composite fabric reduces weight by 30% while maintaining high strength, and the special coating treatment makes the backpack self-cleaning function. In the tent manufacturing, the tear resistance index of composite polyester fabric reaches more than 50N. Combined with the innovative seam sealing process, the safety and comfort of outdoor camping are greatly improved.

Sustainable development breakthrough

The research and development of environmentally friendly Combined Polyester Fabric has made significant progress. Some leading manufacturers have successfully developed composite fabrics with a recycled polyester content of 70%, with performance indicators comparable to those of native materials. Bio-based polyester composite fabrics have begun to enter the mass production stage, with their carbon footprint being reduced by 45% compared to traditional products. An innovative physical recycling process can completely separate the various layers of composite fabrics, increasing the material recycling rate to more than 90%. These breakthroughs enable outdoor equipment to maintain high performance while being more in line with environmental protection concepts and sustainable development requirements.

Market impact and future trends

Combined Polyester Fabric's technological advancement is reshaping the outdoor equipment market. Professional evaluation shows that equipment using new composite fabrics performs significantly better than traditional products in extreme environmental testing. Consumer survey data show that high performance and environmentally friendly characteristics have become key factors in purchasing decisions. In the future, with the development of intelligent textile technology, composite polyester fabrics will integrate more innovative functions, such as temperature adaptive adjustment, energy collection and storage, etc., further expanding the possibilities of outdoor equipment.

From materials science to manufacturing processes, Combined Polyester Fabric’s innovation has brought a qualitative leap to the outdoor equipment industry. This fabric not only solves the contradiction between protection, comfort and weight of traditional outdoor equipment, but also responds to the needs of the environmental protection era through the path of sustainable development. With the continuous advancement of technology, composite polyester fabrics will surely give birth to more breakthrough outdoor equipment solutions, providing outdoor sports enthusiasts with a safer, more comfortable and more environmentally friendly product experience.

English

English русский

русский عربى

عربى