Why has Printed Composite Fabric become an innovative material in the textile industry?

2025-05-22

1. The rise of functional materials: driven by market demand

In today's textile market, the rise of functional materials represents consumers' higher requirements for the comprehensive performance of materials. Traditional textiles often focus on appearance and comfort, while ignoring the durability and environmental adaptability of materials. However, as consumers' requirements for quality of life and product experience continue to increase, functional materials have gradually become the mainstream of the market. They not only provide better performance, but also can cope with various external environmental challenges.

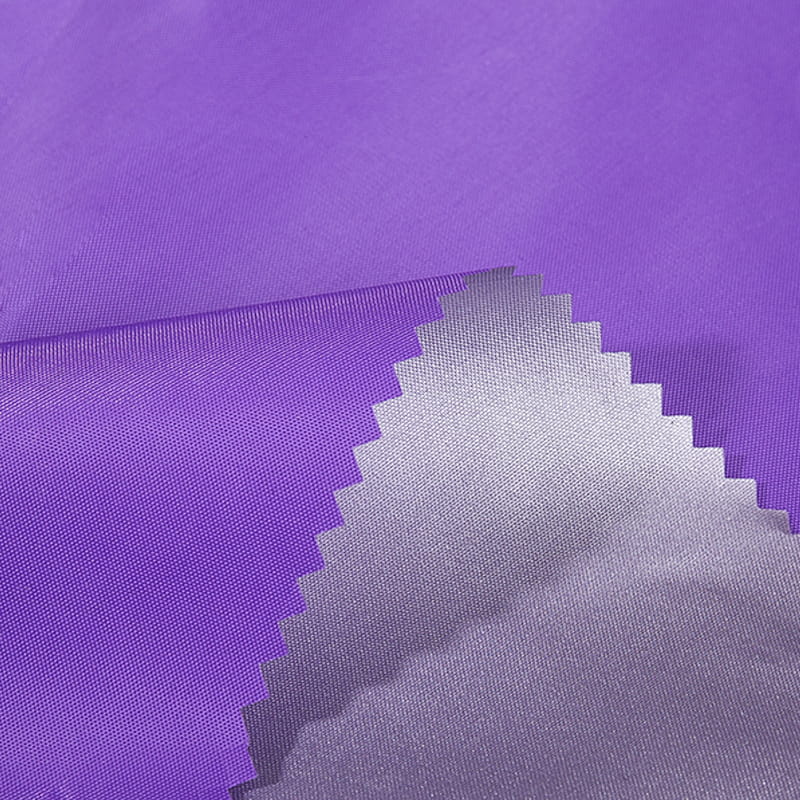

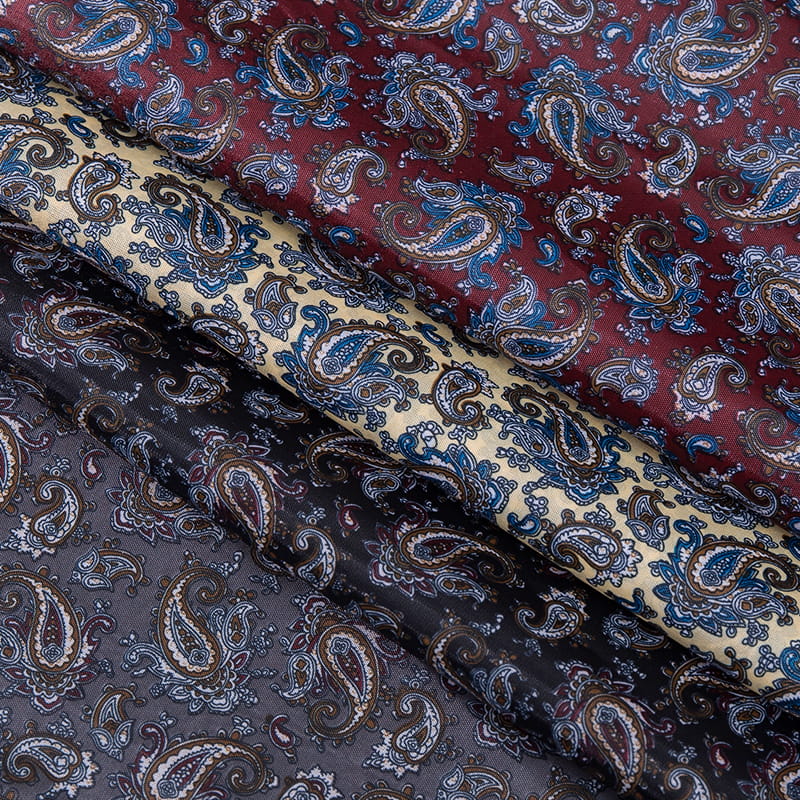

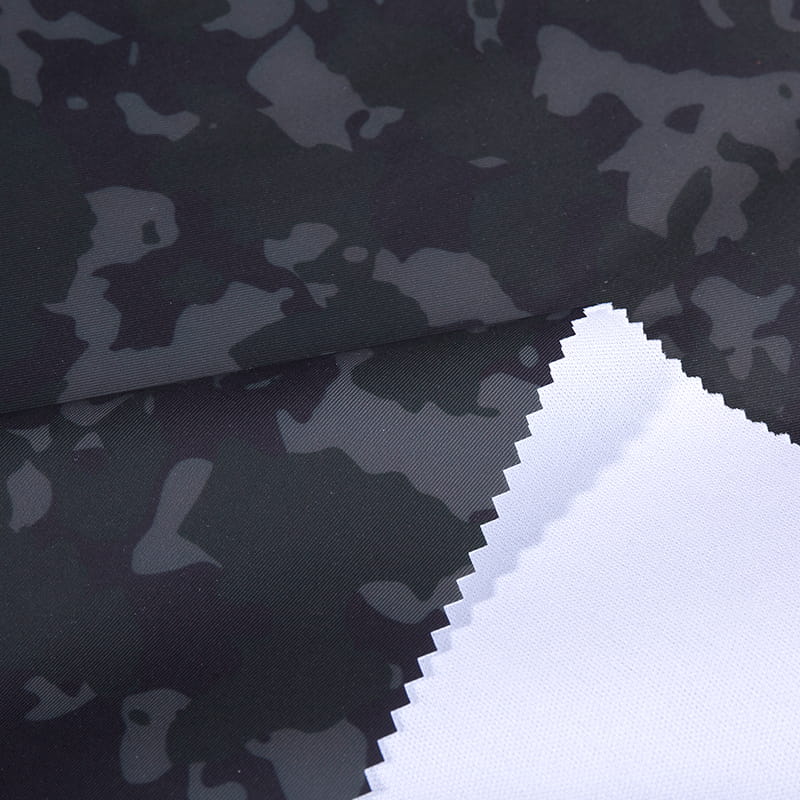

Printed Composite Fabric is the representative of such functional materials. Its innovative composite material design breaks the limitations of traditional textiles in physical properties and meets the higher demands of modern consumers for fabric durability and adaptability. Through its unique design, Printed Composite Fabric gives the fabric higher wear resistance and tear resistance, enabling it to maintain excellent performance during long-term use and avoid damage due to external forces.

2. Improve physical properties: wear resistance and tear resistance

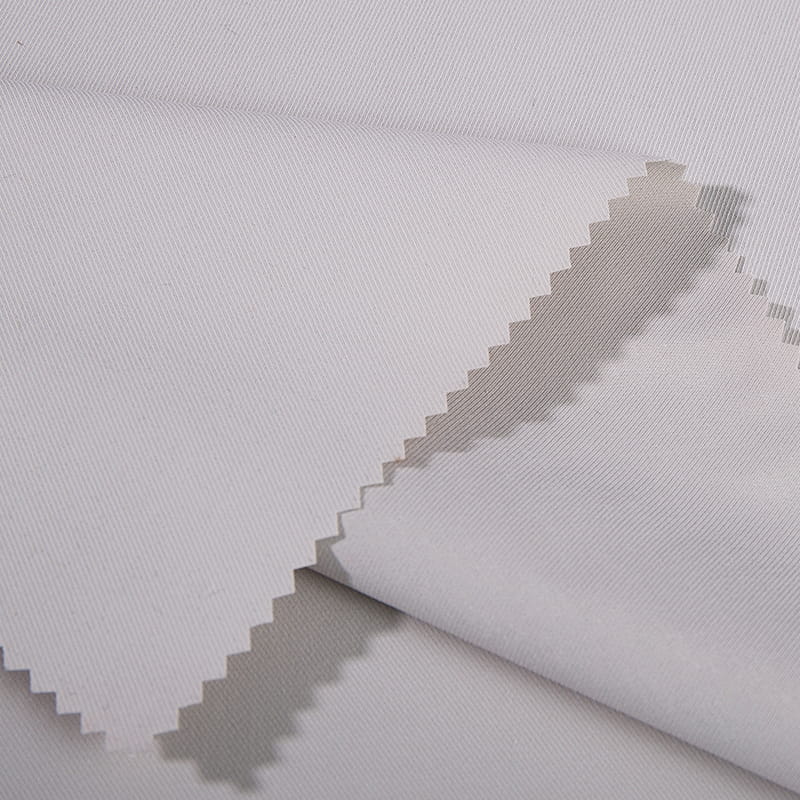

The versatility of Printed Composite Fabric is first reflected in its excellent physical properties. Through the innovative design of composite materials, the wear resistance of this fabric has been significantly improved. Traditional textiles are prone to wear and tear during long-term use, while Printed Composite Fabric can maintain its original performance and extend its service life during long-term friction and use. This feature allows Printed Composite Fabric to maintain high durability even in high-load use situations.

In addition, Printed Composite Fabric also has excellent tear resistance. Tear resistance means that the fabric is not easy to tear or damage when it is subjected to external forces. Through the carefully designed composite material structure, Printed Composite Fabric can effectively resist the tearing force from the outside and maintain the integrity of the fabric. This allows it to maintain stable performance in the face of harsh conditions and avoid easy tearing.

3. Provide UV protection: Enhanced functionality

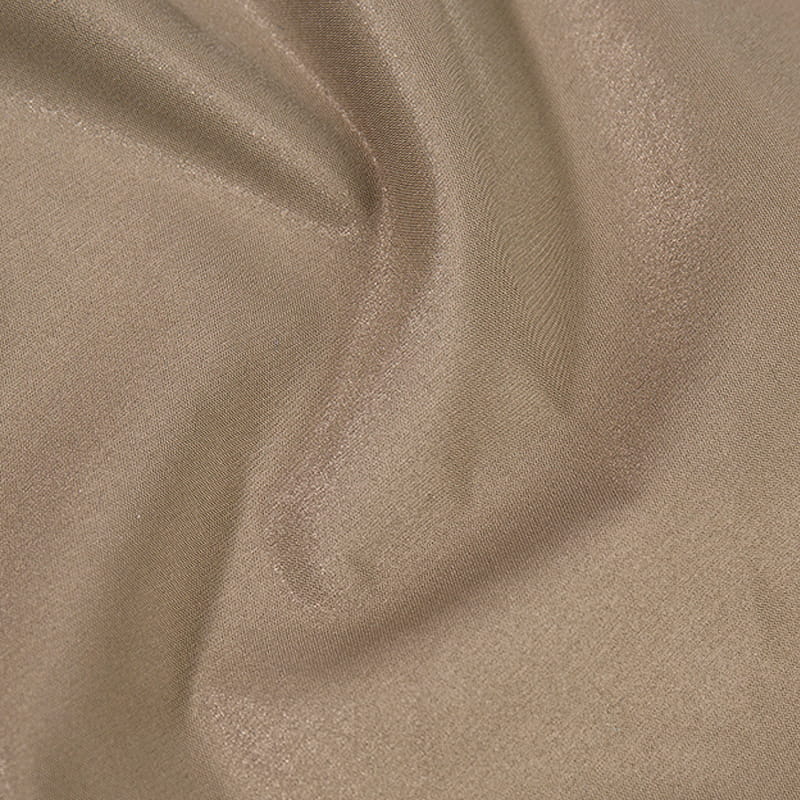

In addition to basic wear resistance and tear resistance, Printed Composite Fabric also has UV resistance, which makes it play an important role in protecting the wearer from UV radiation. Ultraviolet radiation is harmful to human health, and long-term exposure to UV rays may cause skin lesions and premature aging. However, the anti-UV function of Printed Composite Fabric can effectively block the penetration of UV rays and reduce the damage of UV rays to the skin.

Through the design of composite materials, Printed Composite Fabric incorporates this function into the fabric, so that it provides additional protection during daily use. Compared with traditional fabrics, Printed Composite Fabric not only meets consumer needs in appearance and comfort, but also performs better in protection function. This new functionality enables Printed Composite Fabric to improve the wearer's sense of security and comfort while fighting against various adverse factors in the natural environment.

4. Perfect combination of comfort and functionality

Although Printed Composite Fabric has strong functionality, it can still retain the comfort of traditional textiles. Through the unique design of composite materials, Printed Composite Fabric not only improves the physical properties of the fabric, but also maintains the softness and comfort of the fabric. Whether in daily wear or in an environment with special functional requirements, Printed Composite Fabric can provide an ideal comfortable experience.

This perfect combination of comfort and functionality is one of the most significant advantages of Printed Composite Fabric. Its design not only focuses on the performance improvement of the fabric, but also fully considers the wearing experience. When consumers wear products made of Printed Composite Fabric, they can feel its good fit with the skin, avoiding the discomfort caused by traditional functional materials being too hard or rough. This innovative design makes Printed Composite Fabric stand out in many fields and become a leader in functional materials.

5. Adapt to multiple environments: functional scalability

In addition to wear resistance, tear resistance and UV resistance, the composite design of Printed Composite Fabric also makes it more adaptable. For example, its functional scalability enables Printed Composite Fabric to add waterproof and fireproof functions according to different needs. The addition of these functions enables Printed Composite Fabric to play a role in more complex and extreme environments, meeting the needs of modern consumers for multifunctional materials.

By continuously improving functionality, Printed Composite Fabric can not only adapt to various environments in daily life, but also cope with the challenges of some special occasions. This functional scalability gives it a wide range of application potential in multiple industries and has become an important trend in the future development of the textile industry.

English

English русский

русский عربى

عربى