Industry Observation: How Combined Polyester Fabric Reshapes the New Pattern of Textile Industry

2025-06-05

Combined Polyester Fabric's market demand continues to grow

In recent years, the demand for Combined Polyester Fabric (Composite Polyester Fabric) in the global textile market has shown a significant upward trend. As consumers' demand for functional clothing increases, this fabric that combines durability, comfort and environmental protection is becoming the new favorite of the industry. Data shows that the global Combined Polyester Fabric market size has exceeded US$20 billion in 2024, and is expected to grow at an average annual rate of 6.8% in the next five years.

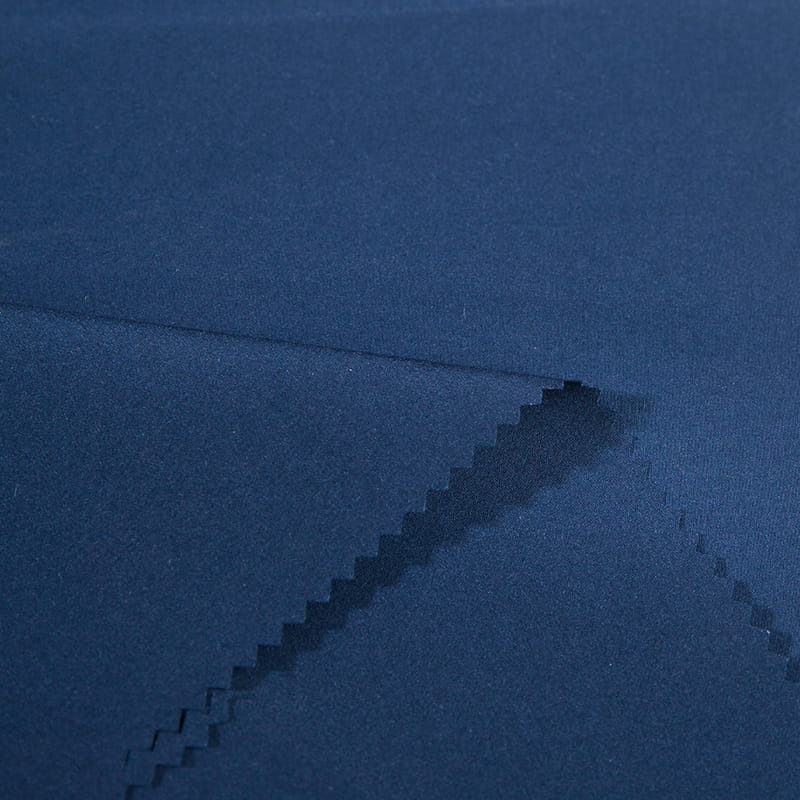

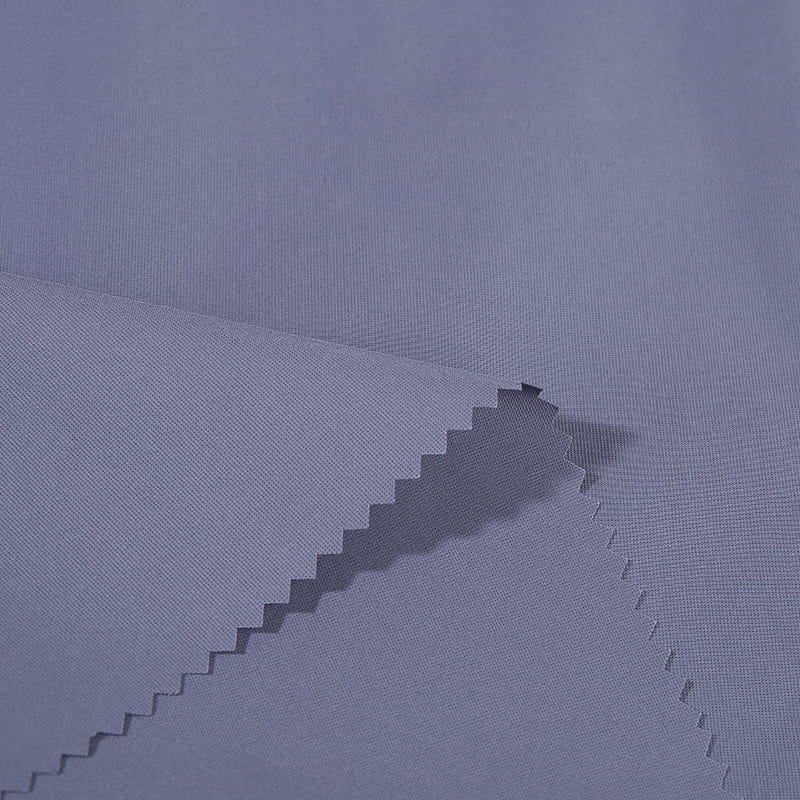

Combined Polyester Fabric is popular mainly due to its excellent performance. Compared with traditional pure cotton or ordinary polyester fibers, composite polyester fabrics perform better in wrinkle resistance, wear resistance and color fastness, and have good breathability and moisture-absorbing and sweating functions, making it occupy an important position in sportswear, outdoor equipment and home textiles. In addition, with the popularization of sustainable fashion concepts, the application of recycled polyester fibers has further promoted the market expansion of Combined Polyester Fabric.

Technological innovation drives Combined Polyester Fabric performance upgrade

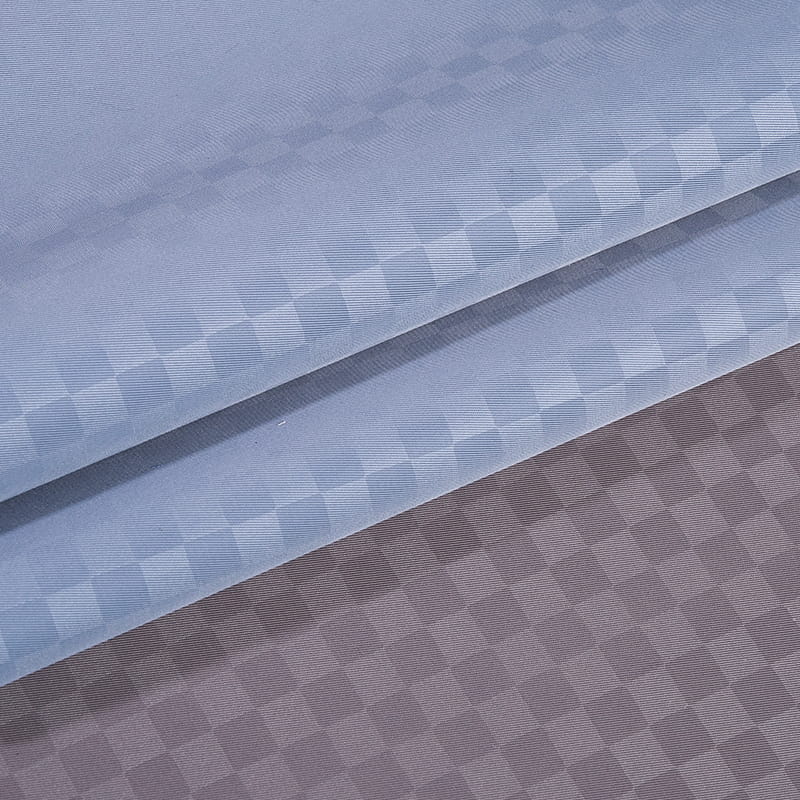

Against the backdrop of continuous progress in textile technology, Combined Polyester Fabric's production process has ushered in a major breakthrough. The application of new composite spinning technology allows polyester fibers to be more closely combined with other high-performance fibers such as spandex, nylon or natural fibers, thus giving the fabric more diverse functional characteristics. For example, some high-end Combined Polyester Fabrics have achieved additional functions such as temperature regulation, antibacterial and odor prevention, and even UV protection.

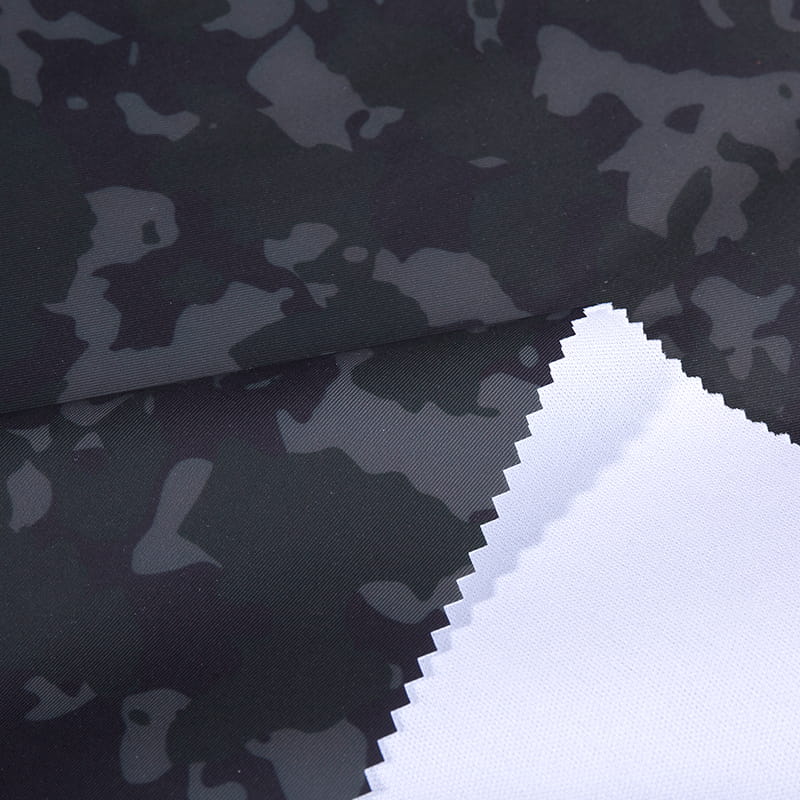

The introduction of nanotechnology has also revolutionized the Combined Polyester Fabric. By performing nano-level treatment on the fiber surface, the fabric can obtain self-cleaning, waterproof and oil-resistant properties, greatly extending the service life of the product. At the same time, the maturity of digital printing technology has enabled composite polyester fabrics to present finer patterns and brighter colors, meeting the fashion industry's demand for diversified designs.

Sustainable development helps Combined Polyester Fabric industry transformation

In the context of increasingly strict global environmental regulations, the Combined Polyester Fabric industry is accelerating its transformation toward sustainable development. Unlike traditional petroleum-based polyester fibers, the new generation of bio-based polyester fibers are made of renewable raw materials such as corn starch or sugar cane, which greatly reduces carbon emissions. What is more worth noting is that the breakthrough in chemical recycling technology has enabled waste polyester textiles to be efficiently decomposed and respinned to form a true closed-loop production system.

Many leading textile companies have begun to promote the "Marine Recycled Polyester" project, which has not only solved environmental problems but also created new commercial value by recycling marine plastic waste. Industry analysts pointed out that by 2025, composite polyester fabrics produced with recycled materials will account for more than 30% of the total market, which marks the gradual development of the textile industry in the textile industry.

Combined Polyester Fabric's future application prospects

With the popularity of smart wearable devices, Combined Polyester Fabric is developing towards intelligence. Researchers have successfully combined conductive fibers with polyester substrates to develop smart fabrics that can monitor physiological indicators such as heart rate and body temperature. Such innovative products are expected to open up new markets in the fields of medical health, sports training and safety protection.

In addition, the application of Combined Polyester Fabric in the fields of construction and automotive interiors is also worthy of attention. Its excellent weather resistance and easy-to-clean properties make it ideal for alternatives to traditional materials. Especially in the context of the rapid development of new energy vehicles, the demand for lightweight and excellent flame retardant composite polyester interior materials has surged. Experts predict that the growth rate of this segment is expected to reach more than 12% in the next three years.

English

English русский

русский عربى

عربى