2025 Printed Polyester Fabric Market Trends: Personalized Customization and Sustainable Production

2025-06-12

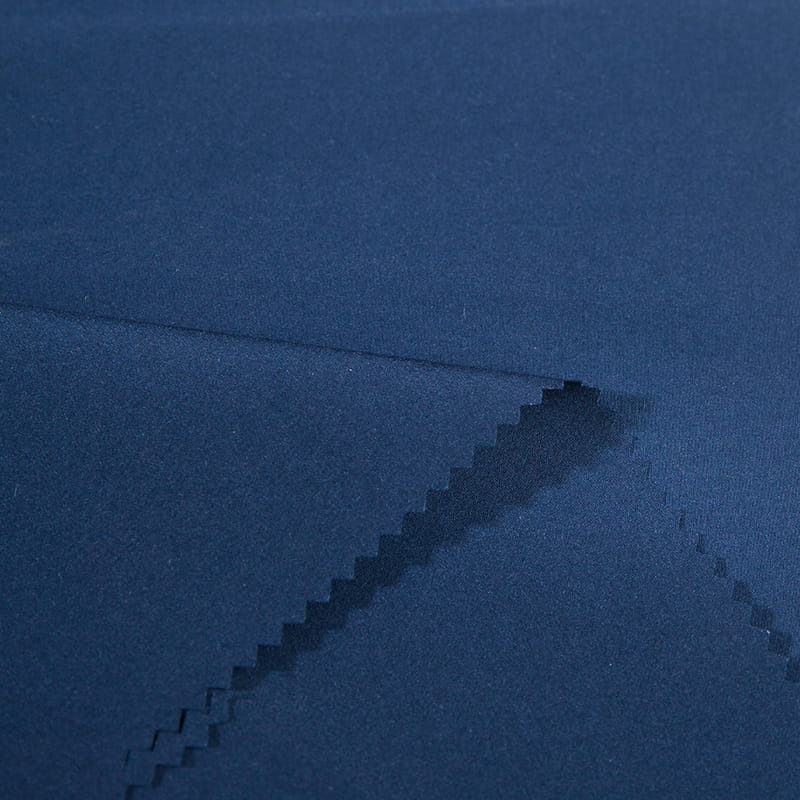

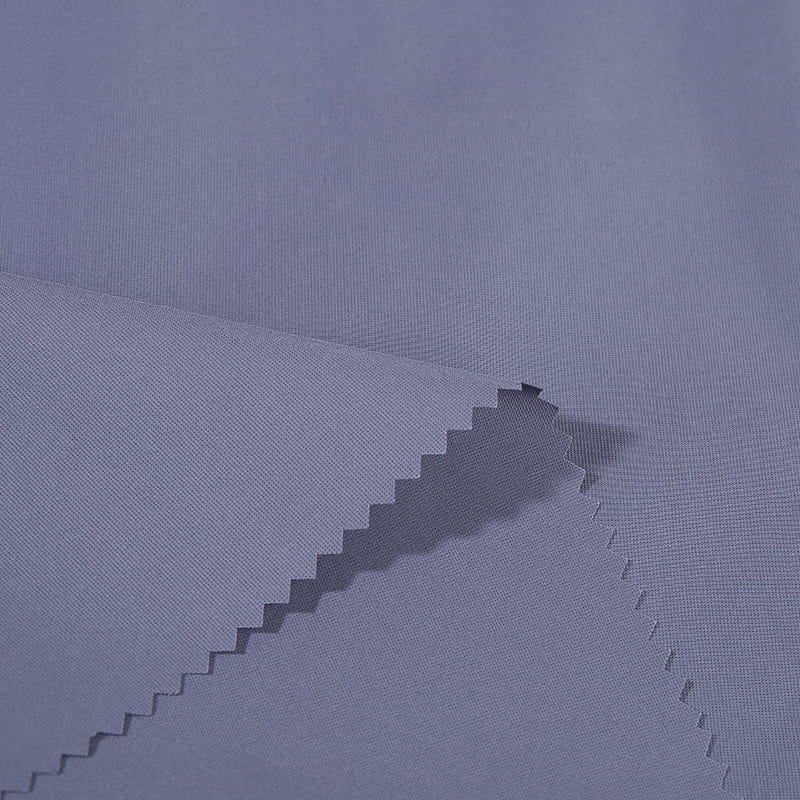

In 2025, when the global textile market continues to change, the field of Printing Polyester Fabric is undergoing a profound transformation. Consumers' desire for unique products is increasing day by day, and the awakening of environmental awareness has also prompted the entire industry to accelerate its move towards sustainable development. These two major trends - personalized customization and sustainable production, are reshaping the market structure of Printing Polyester Fabric.

Personalized customization: meet diverse consumer needs

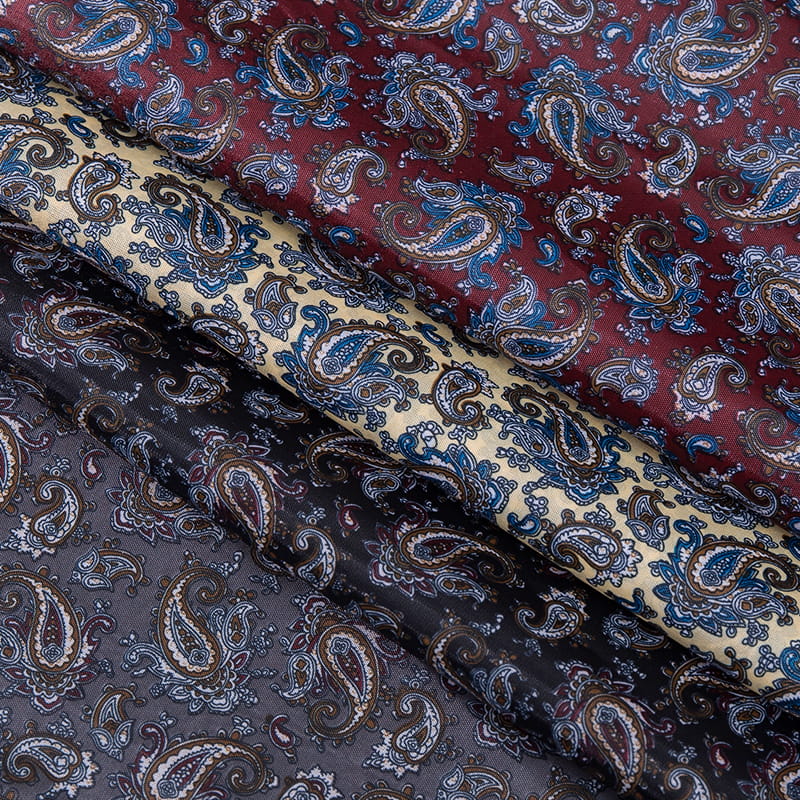

As consumer groups become increasingly segmented, consumers are no longer satisfied with the same print patterns. From fashion clothing to home furnishings, demand for personalized custom Printing Polyester Fabric has exploded. In the fashion industry, young consumers pursue outfits that show their personality, hoping that the prints on the clothing can reflect their interests, hobbies, values or unique styles. This demand has promoted the diversified development of printing design, from the reproduction of niche cultural elements and artistic paintings to the transformation of consumer personal photos and creative ideas into fabric printing, everything is available.

At the technical level, the maturity of digital printing technology provides strong support for personalized customization. Compared with traditional printing technology, digital printing does not require plate making and can quickly and accurately print various complex patterns on polyester fabrics. This not only greatly shortens the production cycle and reduces the cost of small batch production, but also allows designers and consumers to achieve more creativity. Whether it is a single piece customization or a small batch order, digital printing can be easily dealt with, meeting the market's requirements for rapid response and personalized design. At the same time, with the rise of online customization platforms, consumers can choose fabric background colors, printing patterns online through simple operations, and even participate in the design process to achieve an interactive customization experience with merchants, further promoting the popularization of personalized customization in the Printing Polyester Fabric market.

Sustainable Production: The Inevitable Choice to Respond to Environmental Challenges

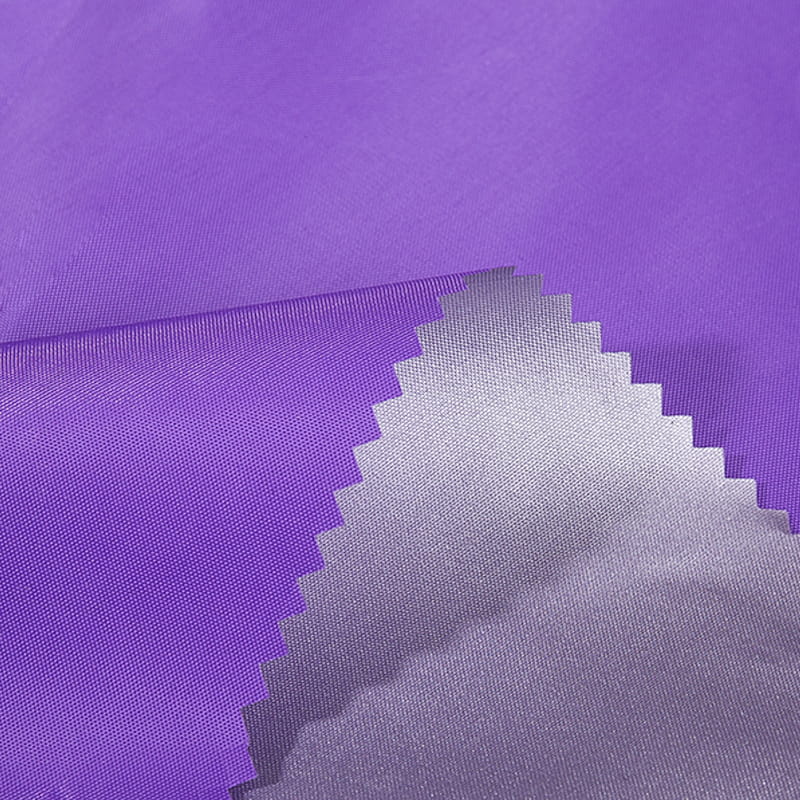

Environmental pressures and consumers' preference for green products are prompting the Printing Polyester Fabric industry to fully promote sustainable production. In the raw material link, the application of recycled polyester is gradually becoming widespread. By recycling discarded plastic bottles, polyester fiber products, etc., it is processed and converted into recycled polyester fibers for the production of Printing Polyester Fabric. This move not only reduces dependence on native oil resources, but also reduces waste pollution to the environment. Many brands have begun to use fabrics containing a proportion of recycled polyester to demonstrate their environmental commitments and win consumer recognition.

In terms of printing technology, environmentally friendly printing technologies continue to emerge. Some chemical dyes and additives used in traditional printing processes contain harmful substances, which pose a threat to the environment and human health. Nowadays, environmentally friendly processes such as water-based ink printing and plant dye printing have been more used. Water-based inks use water as solvent, with less volatile organic compounds (VOCs) emissions, and have good color fastness and printing effects. Plant dyes are derived from natural plants, such as indigo, madder, etc., which are not only environmentally friendly, but also give the fabric a unique color and texture. In addition, some companies are also exploring energy-saving and emission reduction technologies in the digital printing process, such as optimizing equipment energy management and improving ink utilization, to reduce the carbon footprint of the entire production process.

In production management, the concept of circular economy is also gradually implemented in the Printing Polyester Fabric industry. Enterprises have begun to focus on the management of product life cycle, considering the recyclability and degradability of fabrics from the design stage. At the same time, by establishing a recycling system, consumers are encouraged to return discarded printed polyester products, and enterprises classify, process and reuse them, forming a closed-loop industrial chain from production to consumption to recycling, and minimizing resource waste.

Market Challenges and Coping Strategies

Although personalized customization and sustainable production bring new opportunities to the Printing Polyester Fabric market, it also comes with many challenges. In terms of personalized customization, how to meet consumers' diverse needs while ensuring the stability of product quality is a major problem. Different design requirements may put different requirements on printing process and fabric performance. Enterprises need to continuously optimize production processes and improve technical level to ensure that every customized product can meet high quality standards. In addition, personalized customization often involves small batches and multiple batches of production, which poses higher challenges to the company's supply chain management and cost control capabilities. Enterprises need to use information technology to achieve accurate allocation of production resources and reduce operating costs.

For sustainable production, high cost of technological innovation and market awareness need to be improved are the main obstacles. The research and development of environmentally friendly raw materials and printing technology requires a lot of capital and manpower, and the initial production costs may be high, which to a certain extent limits its large-scale promotion. At the same time, some consumers lack the awareness of the value of sustainable products and prefer to choose low-priced traditional products. In this regard, on the one hand, the industry needs to strengthen technology research and development cooperation, share innovative achievements, and reduce the cost of technology application; on the other hand, it needs to increase environmental protection publicity, and through education and guidance, consumers' awareness and acceptance of sustainable Printing Polyester Fabric, thereby promoting market demand growth.

Looking ahead, personalized customization and sustainable production will continue to dominate the development of the Printing Polyester Fabric market in 2025 and beyond. With the continuous advancement of technology and the continuous transformation of consumer concepts, printed polyester fabrics will contribute more to environmental protection while meeting people's personalized aesthetic needs and achieve win-win development of fashion and environmental protection.

English

English русский

русский عربى

عربى