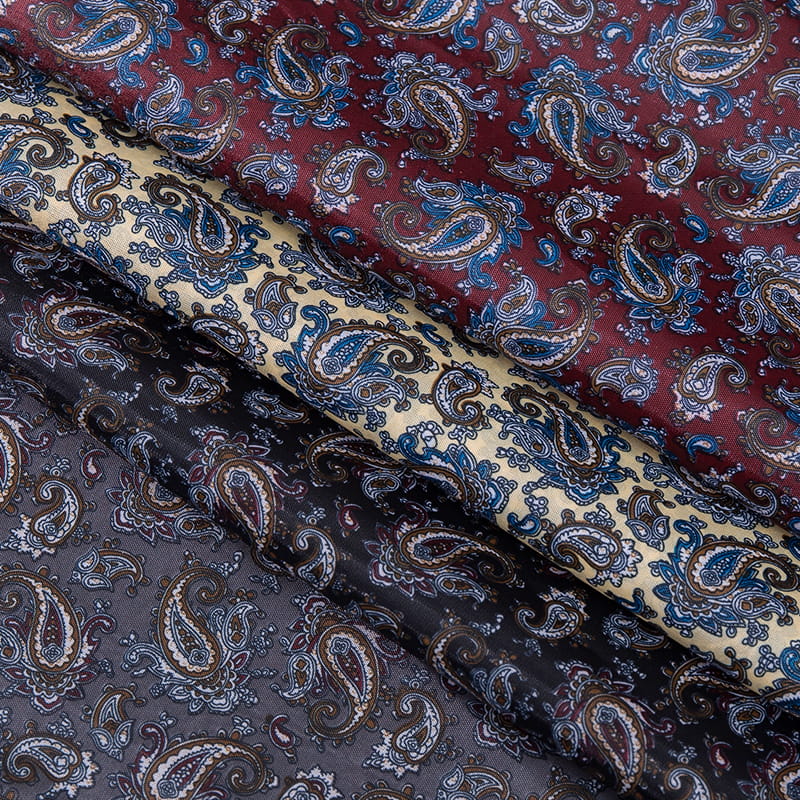

Satin Poly Pongee’s anti-wrinkle treatment technology and smooth touch optimization in high-end fashion

2025-06-19

In the field of high-end fashion, the texture and functionality of fabrics directly determine the quality and value of clothing. Satin Poly Pongee (Satin Poly Pongee) has become one of the fabrics favored by designers due to its unique luster and crispness. However, traditional Satin Poly Pongee has certain limitations in wrinkle resistance and touch, and it is difficult to meet the strict requirements of high-end fashion for details and wearing experience. In recent years, with the continuous innovation of textile technology, anti-wrinkle treatment technology and smooth touch optimization solutions for Satin Poly Pongee have been emerging, bringing new quality improvements to high-end fashion.

The features and traditional limitations of Satin Poly Pongee

Satin Poly Pongee is a fabric made of polyester fiber as the raw material and is made of satin texture. Its surface has a satin-like luster, a tight texture and good wear resistance. It is often used to make high-end fashions such as gowns and suit jackets. However, the characteristics of the polyester fiber itself cause Satin Poly Pongee to easily wrinkle during the wear and folding process, affecting the overall shape and aesthetics of the clothing. In addition, although the fabric has a crisp feel, the touch is relatively rough, which is different from the delicate and smooth texture pursued by high-end fashion. This limitation has prompted the industry to continuously explore improved technologies to enhance the applicability of Satin Poly Pongee in the high-end fashion field.

Innovation breakthrough in anti-wrinkle treatment technology

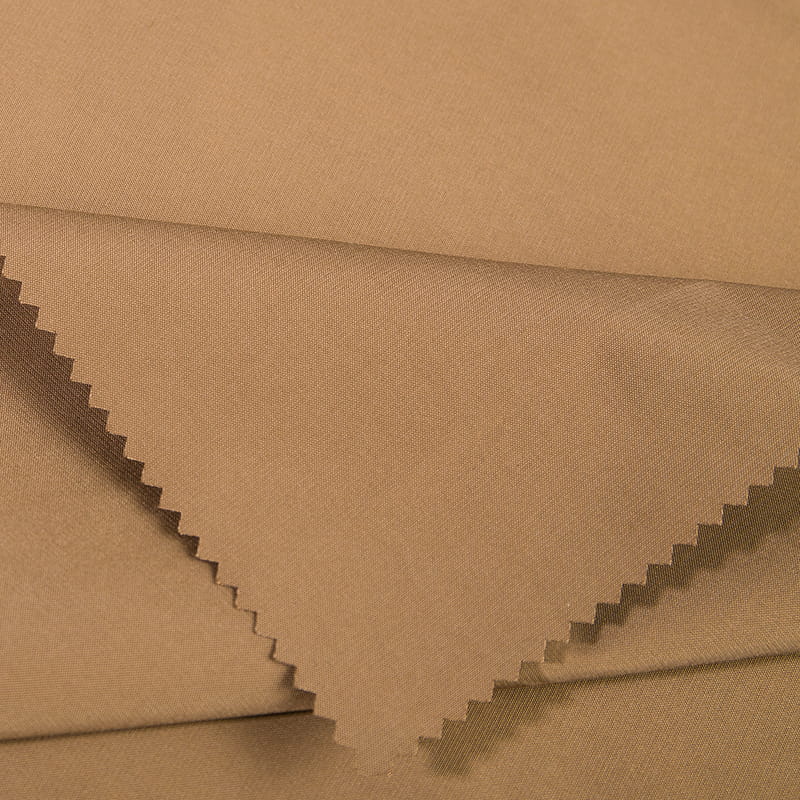

In order to solve the wrinkle anti-problem problem of Satin Poly Pongee, the industry has invested a lot of energy in technology research and development to form a variety of effective wrinkle anti-problem solutions. Chemical finishing technology is one of the most widely used methods. By applying anti-wrinkle finishing agents on the surface of the fabric, the active ingredients in these finishing agents can react cross-link with polyester fiber molecules to form a mesh structure, which enhances the binding force between the fibers, thereby reducing the relative displacement of the fibers and achieving anti-wrinkle effect. For example, polycarboxylic acid anti-wrinkle finishing agent is used to esterify with the hydroxyl group in polyester fiber under a certain temperature and catalyst action, which significantly improves the wrinkle recovery performance of the fabric.

Physical mechanical finishing technology also plays an important role in anti-wrinkle treatment. Through special mechanical processing methods, such as high-temperature shaping, super-feeding tentering and other processes, the internal structure of the fabric is changed. During the high-temperature setting process, under high temperature and high pressure conditions, the molecular chain of the polyester fiber is stretched and fixed in a new form after cooling, so that the fabric can obtain stable wrinkle resistance; the over-feeding tentering process appropriately increases the feeding amount, making the tissue structure of the fabric more uniform during the stretching process, reducing the possibility of wrinkles. In addition, the application of new nanotechnology has brought new breakthroughs in anti-wrinkle treatment. The nano-scale wrinkle-resistant material is evenly attached to the surface of the fabric or the fibers, and the small size effect and high specific surface area characteristics of the nano-material can be used to further improve the wrinkle-resistant ability of the fabric.

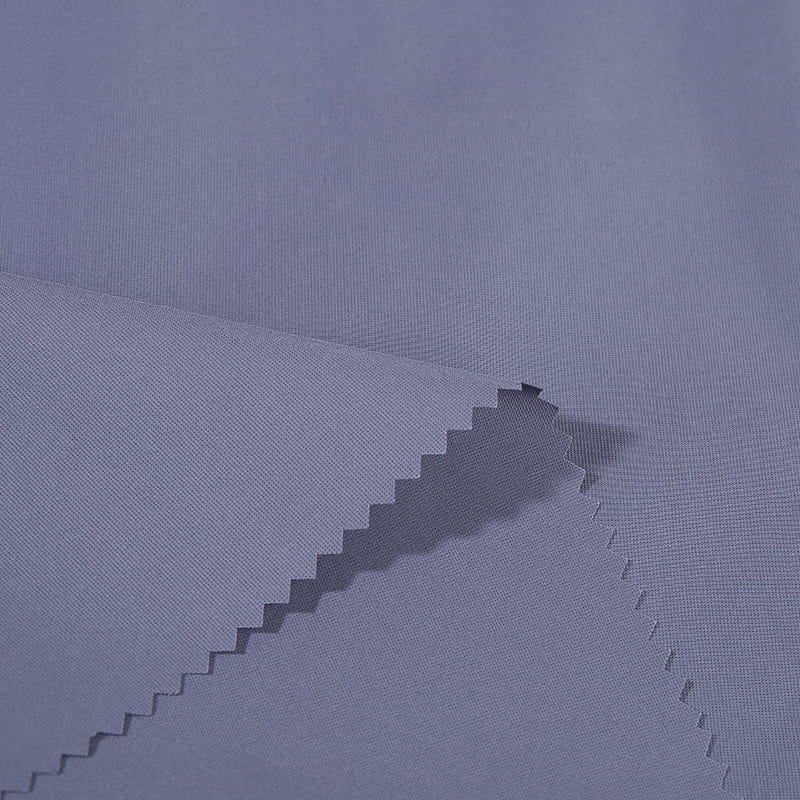

Optimization solution for smooth touch

High-end fashion has extremely high requirements for the smooth touch of Satin Poly Pongee, and for this reason, the industry optimizes it from multiple dimensions. In terms of raw material selection, finer denier polyester fibers are used for woven. The fine denier fiber has a larger specific surface area, and the woven fabric feels softer and more delicate. At the same time, by special surface modification treatment on the fibers, such as adding softener masterbatches, a lubricating film is formed on the surface of the fibers, reducing the friction coefficient between the fibers, thereby enhancing the smooth touch of the fabric.

In the post-organization process, soft finishing is the key link. Common soft finishing agents include silicone, soft film, etc. Silicone softener can form a continuous elastic film on the surface of the fabric, giving the fabric excellent softness, smoothness and drape; soft film softener reduces friction between the fibers through adsorption with the fiber surface, making the fabric feel more plump. In addition, bioenzyme finishing technology has been gradually applied to the touch optimization of Satin Poly Pongee. Bioenzymes can selectively act on the fiber surface, remove hair and impurities on the fiber surface, make the fabric surface smoother, thereby improving the touch.

The coordinated development of anti-wrinkle and touch optimization

It is worth noting that Satin Poly Pongee’s anti-wrinkle treatment technology and smooth touch optimization do not exist in isolation, but are interrelated and coordinated. On the one hand, some technologies and materials used in the anti-wrinkle treatment process, such as nanomaterials, silicone finishing agents, can improve wrinkle resistance while also help improve the touch of the fabric; on the other hand, the optimization of the smooth touch can reduce the friction of the fabric during the wear and folding process, and indirectly reduce the probability of wrinkle generation. For example, the fabric feels smoother through soft finishing, and the friction between the fibers is reduced. When subjected to external forces, the fibers are more likely to return to their initial state, thereby enhancing the wrinkle resistance of the fabric.

In the future, with the continuous advancement of textile technology, Satin Poly Pongee will be more widely used in the high-end fashion field. By continuously innovating anti-wrinkle treatment technology and smooth touch optimization solutions, Satin Poly Pongee will achieve the dual improvement of wrinkle resistance and touch while maintaining unique luster and clarity, bringing more possibilities to the design and quality of high-end fashion, and meeting consumers' growing demand for high-quality clothing.

English

English русский

русский عربى

عربى