Decoding Twisted Yarn Fabric: A Comprehensive Guide to Its Benefits, Identification, and Care

2025-12-11

Welcome to the authoritative guide on Twisted Yarn Fabric. As a cornerstone in high-quality textile production, this unique material is often lauded for its superior durability, exceptional texture, and versatile applications across the apparel and home goods sectors. Understanding this fabric goes beyond simply recognizing its name; it requires a deep dive into the engineering of the yarn itself—the process of twisting multiple single strands (or plies) into a unified, stronger thread. This intricate method not only binds the fibers together but also fundamentally alters the fabric's final performance characteristics, setting it apart from materials made with standard, low-twist yarns. Whether you are a textile professional, a fashion student, or simply a consumer seeking long-lasting, quality materials, this guide will illuminate the complex yet rewarding world of textiles engineered with a twist. We aim to provide clear, professional, and in-depth insights that empower you to appreciate and utilize this fabric to its full potential, ensuring you make informed choices based on structural integrity and long-term value.

The Fundamental Nature of Twisted Yarn Fabric

The essence of a high-performance textile often resides not in the raw fiber, but in how those fibers are prepared and integrated into a stable, usable thread. The creation of Twisted Yarn Fabric hinges entirely on the process of introducing a predetermined number of twists per unit length into the yarn. This twisting process is not merely for aesthetics; it is a critical mechanical operation that significantly enhances the yarn’s cohesive strength and resilience. When multiple single yarns are twisted together, they form a ply yarn, or a two-ply, three-ply, or multi-ply yarn. This strategic inter-locking of fibers prevents slippage, reduces breakage during weaving or knitting, and contributes a distinctive hand-feel to the finished fabric. The number of twists—measured in TPI (twists per inch) or TPM (twists per meter)—is precisely controlled to achieve different outcomes, ranging from the smooth, high-luster finish of highly-twisted yarns used in fine shirting, to the bulkier, softer feel of low-twist yarns used in towels. This attention to detail in the yarn's structure is what provides the foundation for the fabric's long-term performance and textural appeal, making the yarn twist a definitive factor in material quality.

Defining the Core Concept of Twisted Yarn Fabric

The term Twisted Yarn Fabric refers specifically to any woven or knitted material where the constituent threads have undergone a significant twisting process, typically involving two or more single yarns being twisted together to form a complex, multi-ply structure. This engineering choice is paramount for textiles intended for heavy use or those requiring exceptional drape and resistance to abrasion. The deliberate twisting imparts a high degree of inter-fiber friction, which translates into substantially greater tensile strength compared to a fabric made from equivalent single-ply yarns. The resulting textile is inherently less prone to pilling, fraying, and general wear and tear. Furthermore, the twist affects the yarn's absorbency and luster; highly-twisted yarns often yield crisper, more reflective fabrics, while lower-twist yarns retain more air, leading to softer, more absorbent materials. This foundational concept underpins the fabric's ability to maintain its integrity and aesthetic quality through repeated laundering and long-term use, justifying its premium status in the textile market.

- Ply Yarn Structure: The construction involves two or more single yarns twisted together, enhancing uniformity and strength.

- Twist Direction: Twists can be 'S' (right-handed) or 'Z' (left-handed), which affects the fabric's surface texture and how it interacts with light.

- Twist Multiplier: A calculated measure used to determine the optimal twist level based on the fiber type and intended end-use of the fabric.

Key Characteristics of Yarn Twisting

Yarn twisting is a sophisticated process with several key characteristics that directly influence the final fabric properties. The main characteristics include the direction of the twist, the amount of twist, and the number of plies used. For instance, a high twist can create crepe fabrics with a distinctive crinkled texture and excellent resilience, while a moderate twist is favored for maximizing the strength and evenness of standard apparel fabrics. The interaction between the twist direction in the single yarn and the subsequent twist direction in the ply yarn is also crucial; typically, an S-twist single yarn is combined with a Z-twist ply yarn (or vice versa) to balance the internal stresses and prevent snarling or bowing in the fabric. This precise control over twist characteristics allows manufacturers to tailor the yarn—and thus the fabric—to highly specific performance criteria, from water-repellency to wrinkle resistance, ensuring maximum functional utility from the textile. Ignoring these characteristics means compromising the structural integrity of the final product.

- Luster Control: Higher twists tend to compact the fibers, reflecting light more uniformly and increasing fabric luster.

- Abrasion Resistance: The tight binding of fibers significantly increases the fabric’s resistance to rubbing and external friction.

- Bulk and Cover: Lower twist levels, especially in short-staple yarns, create more bulk and better fabric coverage.

Exploring the benefits of twisted yarn fabric

The distinct benefits of twisted yarn fabric extend far beyond mere structural integrity, influencing everything from the wearer's comfort to the garment's lifespan. Chief among these advantages is the marked increase in tensile strength, making the textile highly resistant to tearing and breaking under tension, a feature particularly valued in workwear and high-end upholstery. Moreover, the closely-bound fibers dramatically reduce fuzziness and pilling, maintaining a smooth and refined appearance even after extensive use and washing. This results in fabrics that not only look new for longer but also feel better against the skin, offering a superior tactile experience. From an aesthetic perspective, the twisting process can be manipulated to produce unique surface textures, exceptional drape, and a consistent, even color absorption during the dyeing process. These combined performance and aesthetic benefits solidify the fabric’s position as a premium choice for applications where both longevity and sophisticated appearance are paramount, offering a clear return on investment through extended material life. This versatility means the fabric can perform exceptionally in highly technical environments as well as luxury fashion.

- Pilling Resistance: Tightly twisted fibers are less likely to break and migrate to the fabric surface, reducing the formation of unsightly pills.

- Crease Recovery: The increased elasticity imparted by the twist helps the fabric resist wrinkling and recover its shape more readily after compression.

- Enhanced Absorbency: In certain low-twist, multi-ply constructions, the yarn can be engineered to be highly absorbent, ideal for terry or toweling applications.

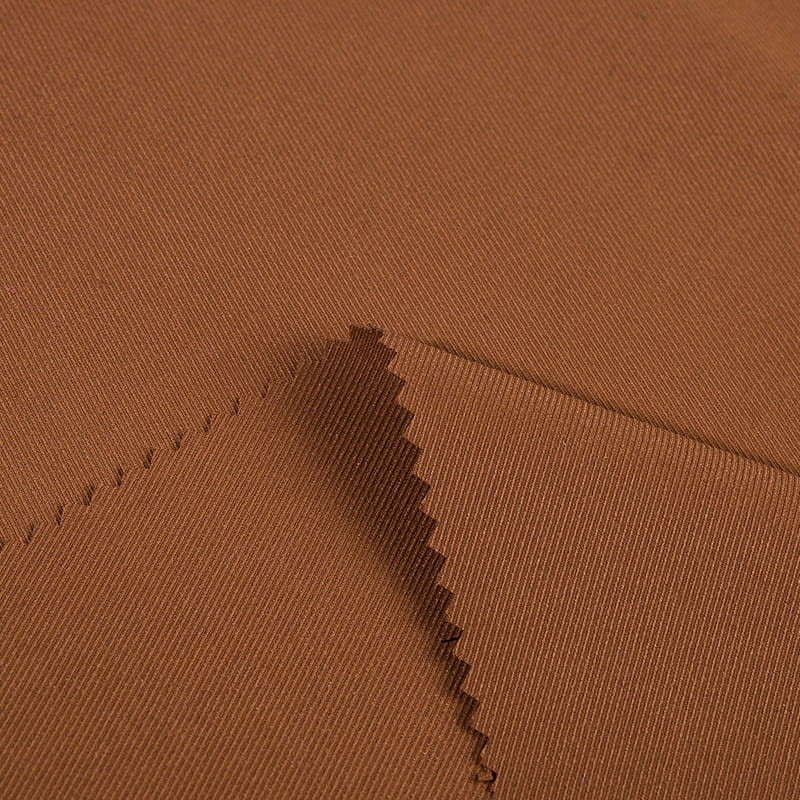

Enhanced Textile Performance and Aesthetics

The enhanced performance profile of textiles made with highly-twisted yarns translates directly into tangible user benefits. For example, in fine wool suiting, a worsted yarn with a high twist yields a fabric that resists bagging at the knees and elbows, maintaining a sharp, tailored silhouette throughout the day. In cotton, a high-twist yarn provides a crispness and cleanliness that is highly desirable in business shirting, improving breathability and reducing the need for heavy starching. Aesthetically, the consistency of the twist ensures a uniform texture and dye uptake, eliminating the patchy or uneven appearance common in low-quality textiles. The refined nature of the surface, due to the minimization of projecting fiber ends, gives the fabric a smooth and sometimes lustrous finish, which is highly prized in luxury textiles. Ultimately, the deliberate engineering of the yarn twist serves as a holistic solution to common textile shortcomings, delivering a product that excels in both function and form, providing a level of quality that is immediately apparent to the discerning eye and touch.

- Improved Hand-Feel: The structure contributes to a firmer, crisper hand in high-twist fabrics, and a softer, fuller hand in balanced-twist fabrics.

- Color Clarity: The compact nature of the twisted yarn ensures clear and even penetration of dyes, resulting in deeper, more vibrant colors.

- Dimensional Stability: The balanced internal forces from the twist help the fabric resist skewing or bowing after washing or cutting.

Practical Applications and Identification

Understanding the practical applications of Twisted Yarn Fabric is key to appreciating its economic and functional value across various industries. From the high-demand environments of industrial textiles to the delicate requirements of luxury fashion, the material's superior strength and resilience make it an indispensable choice. The ability to control the yarn's characteristics through the twisting process allows manufacturers to create bespoke materials for specific end-uses—a high-twist cotton for a crisp poplin, or a lower-twist, multi-ply wool for a durable, soft tweed. Moreover, for consumers and professional buyers, the ability to correctly identify this fabric is a valuable skill that ensures quality control and helps in forecasting the longevity of a garment or item. Correct identification involves a combination of visual inspection, focusing on the evenness and tightness of the weave, and a tactile assessment of the fabric's hand-feel, which is often noticeably firmer and cleaner than its low-twist counterparts. This section delves into where this fabric shines and provides practical methods for its positive identification in the marketplace.

Applications in Textile Manufacturing and twisted yarn fabric for clothing durability

The application of twisted yarn fabric for clothing durability is one of its most critical roles in the textile industry. Garments subject to high-stress activities, such as work uniforms, performance sportswear, and outerwear, require materials that can withstand rigorous use without compromising their structural integrity. The use of multi-ply, highly-twisted yarns in these applications guarantees a fabric with significantly higher tear strength and superior seam slippage resistance. This enhanced durability ensures that clothing maintains its shape and structure longer, delaying replacement cycles and offering better value to the consumer. Beyond rugged applications, twisted yarns are foundational in luxury clothing, particularly in sophisticated worsted wool and high-count Egyptian cottons. In these contexts, the twist ensures a smooth, non-fuzzy surface, a superior drape, and a resistance to permanent creasing, which are hallmarks of high-quality tailoring. The consistent quality provided by the engineered twist is a non-negotiable factor in textiles that aim for both longevity and a premium appearance across a diverse range of products, making it a universal sign of quality construction.

- Denim and Twills: Used to create the high strength and characteristic diagonal line (wale) of these durable weave structures.

- Fine Count Shirting: High-twist cottons are essential for creating the crisp, lustrous finish of luxury poplin and broadcloth.

- Tailored Suits: Multi-ply, balanced-twist worsted yarns provide the necessary resilience and drape for high-end tailoring that resists wrinkling.

Common Apparel and Household Uses

The versatility of textiles made with twisted yarns is demonstrated by their broad utility, ranging from everyday household items to specialized apparel. In the home, highly absorbent, low-twist cotton yarns are commonly used in premium towels, where their structure maximizes surface area and wicking capabilities. Conversely, high-twist yarns are used in durable upholstery and drapery fabrics to resist sun-fading and abrasion from daily use. In apparel, the use spans the entire spectrum: from the smooth, crispness required for professional attire to the rugged, protective qualities needed for heavy-duty trousers. The common thread is the need for a material that offers predictable performance and extended life, a demand that fabrics made from twisted yarns consistently meet. The engineered resilience of these textiles ensures that functional items, such as bedding and curtains, and aesthetic items, like a tailored blazer, retain their essential properties and visual appeal far longer than their low-twist alternatives.

- Upholstery Fabrics: High twist ensures resistance to snagging and surface breakdown on furniture.

- Toweling: Low-twist, multi-ply yarns are used to enhance absorbency and plushness in bath linens.

- Outdoor Gear: High-tenacity, twisted synthetic yarns provide superior strength for backpacks and tents.

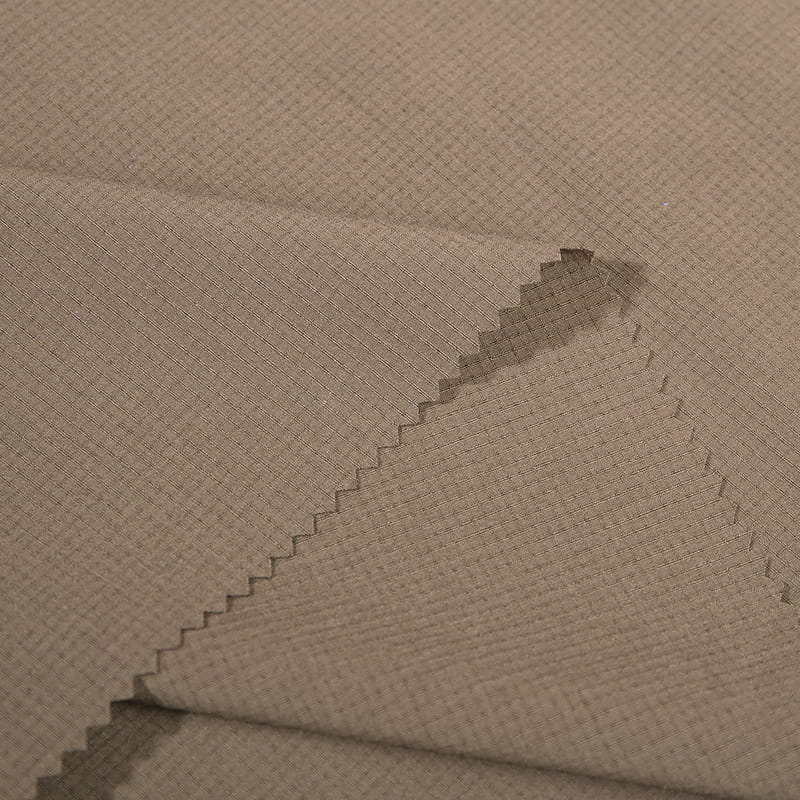

how to identify twisted yarn fabric from other materials

Knowing how to identify twisted yarn fabric is a practical skill for quality assurance and material sourcing. The most reliable method involves a close-up visual examination. A twisted yarn will appear distinctively more compact, even, and rounded compared to a single-ply yarn, which often looks flatter and may show more stray fiber ends (fuzziness). By observing the fabric under magnification, one can usually see the clear inter-locking of the plies. A physical, tactile assessment is also highly informative: fabrics made from high-twist yarns will generally feel firmer, crisper, and sometimes springier due to the internal energy stored in the twist. Conversely, a low-twist fabric will feel softer and perhaps bulkier, but may lack the structural recovery of its twisted counterpart. A simple test involves trying to pull a single thread from the fabric; a twisted yarn will resist splitting and maintain its integrity far better than a standard, untwisted thread. Professionals often use a “twist tester” to measure the TPI, but for consumers, the visual and tactile clues are often sufficient to indicate the superior construction of the material.

- Close Visual Inspection: Look for a round, tightly packed thread appearance within the weave or knit structure.

- Snarling Test (Professional): A high-twist yarn, when untwisted and released, will rapidly curl back on itself due to stored torque.

- Tactile Check: The fabric should feel dense, firm, and have a noticeably smooth, clean surface free of excessive fuzziness.

Visual and Tactile Inspection Techniques

The combination of visual and tactile inspection provides the most accessible way for a non-specialist to identify a premium Twisted Yarn Fabric. Visually, pay attention to the surface cleanliness: the minimization of fiber ends projecting from the yarn creates a very clean surface texture. Hold the fabric up to the light; a twisted yarn fabric often exhibits a more uniform sheen or luster because the twisted structure reflects light more consistently. Tactilely, gently pinch and roll a portion of the fabric between your fingers. A well-constructed twisted yarn material will feel dense and substantial, and if it is a high-twist crepe or worsted, it will possess a noticeable springiness or resilience when compressed. If the material feels overly soft, bulky, and easily separates or pills upon light rubbing, it is likely made from a low-twist or single-ply yarn. Developing an eye for these details is crucial for anyone prioritizing material quality and lifespan over immediate cost, as these subtle characteristics are key indicators of a superior, long-lasting textile product.

- Resilience Test: Gently crumple a small section; twisted yarn fabrics will exhibit better, faster crease recovery.

- Uniformity Check: Look for evenness in the yarn diameter; twisted yarns are generally more uniform than single-ply yarns.

- Shear Check: High-quality twisted fabrics resist skewing (where the vertical and horizontal lines of the weave distort) when pulled on the bias.

Understanding the Material Differences

A true understanding of textile quality requires a clear distinction between materials made with highly-engineered, twisted yarns and those utilizing standard or low-twist singles. The perceived quality difference is not subjective; it is rooted in fundamental structural mechanics. The difference impacts every measurable property of the fabric, including its breaking strength, hand-feel, resistance to abrasion, and ultimate commercial lifespan. When we analyze textiles, we are effectively comparing a meticulously engineered component (the twisted ply) against a simpler, less cohesive one (the single yarn). This section will analytically explore the physical and performance contrasts, highlighting why manufacturers opt for the complexity of twisting for high-end or high-performance fabrics, and how these structural choices manifest in tangible, observable differences in the final material. Grasping this distinction is key for anyone involved in material specification, design, or high-volume purchasing.

Analyzing the difference between twisted yarn and regular yarn fabric

The difference between twisted yarn and regular yarn fabric is rooted in the yarn's construction, which dictates the fabric's performance envelope. A regular (single) yarn is the basic unit, often sufficient for low-stress, disposable, or simple commodity textiles. However, it lacks the internal cohesion and strength required for longevity. A twisted yarn, which is typically a multi-ply yarn, achieves vastly superior strength because the twisting distributes the load across multiple component threads, preventing individual fiber slippage and breakage. This structural advantage translates into a higher resistance to tensile forces and abrasion in the final fabric. Furthermore, the twist acts as a stabilizing force, which imparts better dimensional stability and a cleaner, more refined surface. While regular yarn fabrics are cost-effective, they inherently compromise on key performance metrics such as resistance to pilling and tearing. The choice between the two is therefore a critical balancing act between material cost and expected lifespan and quality, with twisted yarn materials consistently providing a superior, durable, and premium result that justifies the higher production complexity.

- Structural Integrity: Twisted yarns possess internal force balance, providing superior cohesive strength and reducing fiber breakage during processing.

- Fiber Migration: In twisted yarns, fibers are locked in, minimizing migration to the surface and preventing the premature onset of fuzziness and pilling.

- Aesthetic Quality: The evenness of the twisted yarn ensures a smoother, more uniform surface appearance compared to the often-irregular nature of single yarns.

Structural Comparison: Twist vs. Standard Spinning

The structural disparity between a twisted yarn and a standard spun yarn (single yarn) is the primary determinant of the final fabric’s characteristics. Standard spinning is designed to impart just enough twist to hold the fibers together, prioritizing speed and cost-efficiency. The resulting single yarn is adequate but remains relatively weak and prone to fuzziness. In contrast, the twisting process, which combines multiple spun yarns, is a deliberate, secondary operation that is costly but structurally transformative. The combined plies reinforce each other, distributing stress and creating a much stronger, more resilient thread. This fundamental engineering choice allows the resulting fabric to better withstand the dynamic forces of washing, wearing, and repeated flexing without structural failure or rapid aesthetic degradation. The tight, cohesive structure of the twisted yarn means the individual fibers cannot move freely, resulting in a dense, long-lasting fabric structure. This structural superiority is the definitive factor that distinguishes premium textiles from commodity materials, offering measurable improvements in performance.

- Load Distribution: Multi-ply twisted yarns distribute tension evenly, whereas stress in single yarns is concentrated on the weakest point.

- Fiber Ends: Twisted yarns have fewer free fiber ends protruding, leading to a smoother hand-feel and better resistance to pilling.

- Production Steps: Twisted yarn requires a more complex manufacturing process, including the initial spinning plus the plying/twisting stage, which increases the production time and cost.

Performance and Hand Feel Contrast Table

To summarize the key structural and performance trade-offs, the following table illustrates the direct contrast between fabrics constructed from multi-ply, Twisted Yarn Fabric and those using standard, low-twist single yarns. This comparison highlights why the engineered twist is a hallmark of quality.

| Performance Metric | Twisted Yarn Fabric (Multi-Ply) | Regular Yarn Fabric (Single-Ply/Low-Twist) |

| Tensile Strength | Significantly Higher (Excellent Durability) | Lower (Prone to Breakage) |

| Resistance to Pilling/Fuzzing | High (Clean, Long-Lasting Surface) | Low (Prone to Pilling and Premature Wear) |

| Dimensional Stability | Excellent (Resists Skewing/Bagging) | Fair to Poor (Prone to Distortion) |

| Hand Feel (Aesthetics) | Firmer, Crisper, Smoother, More Lustrous | Softer, Bulkier, Fuzzier |

| Cost and Manufacturing Complexity | Higher (Extra Twisting Process Required) | Lower (Fewer Manufacturing Steps) |

Longevity and Maintenance

To maximize the inherent durability of Twisted Yarn Fabric, correct maintenance is crucial. The superior structure provided by the twist means the fabric is built to last, but its longevity is ultimately determined by how well it is cared for. Incorrect washing, drying, or ironing techniques can diminish the benefits of the twist, leading to premature wear, loss of shape, or surface degradation. Because of the density and often-higher fiber content of these premium fabrics, they require thoughtful handling. For instance, high-twist worsteds should be dry-cleaned or professionally steamed to maintain their drape and crease-resistance, while high-twist cottons can withstand machine washing but benefit significantly from cooler temperatures and gentle cycles. The user's adherence to proper maintenance protocols is the final step in ensuring the fabric performs as engineered, retaining its strength, hand-feel, and aesthetic appeal for the entirety of its long expected lifespan. This section offers specific, actionable advice to help preserve the quality of your investment.

Detailed care instructions for twisted yarn fabric

Following detailed care instructions for twisted yarn fabric is the best way to ensure your investment in quality textiles provides its maximum return in longevity and appearance. Due to the tight, compact nature of the yarn, these fabrics often require different handling than loose, low-twist materials. The general principle is to be gentle. For washable items, always use a mild, pH-neutral detergent and a cold or warm water cycle; hot water can cause unnecessary shrinkage and stress the tightly-wound fibers. Avoid harsh bleaches, which can degrade the fiber integrity and weaken the twist. The resilient nature of the twist often means that garments come out of the wash with fewer wrinkles, making minimal ironing necessary, but when pressing is required, use a low to medium heat setting, preferably with steam, and press on the reverse side to protect the surface finish. Proper care mitigates the forces that lead to fiber fatigue, allowing the inherent strength of the twisted yarn to maintain the fabric's structure and aesthetic quality over many years of use. This attention to detail in care extends the usable life far beyond that of standard fabrics.

- Pre-Treat Stains: Treat stains immediately using localized spot-cleaning before washing the entire garment.

- Zipper and Button Safety: Always close all zippers and buttons before washing to prevent snagging on other items or the fabric itself.

- Avoid Overloading: Do not crowd the washing machine; allow ample room for the fabric to move freely and rinse thoroughly.

Washing, Drying, and Storage Best Practices

Best practices for washing, drying, and storage are paramount to maintaining the high performance of Twisted Yarn Fabric. When washing, turning the garment inside out is a simple yet effective way to protect the outer surface from abrasion in the machine. For drying, air drying is highly recommended whenever possible; the weight of the water in a well-twisted fabric can help naturally smooth out wrinkles. If a dryer must be used, select a low-heat or tumble-dry setting and remove the item while it is still slightly damp to avoid excessive heat exposure, which can weaken fibers and cause irreversible shrinkage. Never hang knits made from twisted yarns, as the weight can pull the fabric out of shape; instead, fold them flat. For storage, ensure garments are clean before putting them away for extended periods. Use appropriate hangers for wovens to preserve the shoulder line, and avoid over-stuffing closets, which can cause crushing and unnecessary creasing. Adopting these methodical practices will ensure the structural benefits of the yarn twist are preserved, securing the fabric’s dimensional stability and smooth hand-feel for years.

| Care Step | Best Practice for Twisted Yarn Fabric | Reasoning for Best Practice |

| Washing Temperature | Cold to Warm Water (Max 30°C/85°F) | Prevents excessive shrinkage and preserves fiber integrity against heat damage. |

| Drying Method | Air Dry or Tumble Dry Low/No Heat | Minimizes heat stress and friction, preventing fiber damage and pilling. |

| Ironing | Low to Medium Heat, Always Press on Reverse | Protects the smooth surface finish and prevents direct heat damage to the fiber. |

| Storage | Fold knits; Hang wovens on padded hangers | Maintains the engineered shape and prevents stretching or permanent creasing. |

FAQ (Frequently Asked Questions)

What are the main types of yarn twists (S-twist vs. Z-twist) and how do they affect the final fabric?

The two main types of yarn twists are S-twist (or left-hand twist) and Z-twist (or right-hand twist), named after the direction the fibers spiral, which visually mimics the central bar of the corresponding letter. This twist direction is a foundational element that significantly affects the fabric's texture, performance, and manufacturing process. The primary effect is on balancing the internal stresses of the yarn; for example, single yarns are often Z-twisted, and then two of these are ply-twisted together with an S-twist to create a balanced, stable two-ply yarn. In the final fabric, the twist direction influences the reflection of light (luster) and the direction in which the fabric 'drapes' or 'twills' (e.g., a right-hand twill in denim). Using a consistent, single-direction twist (highly twisted crepe yarns) can create torque, resulting in the characteristic crinkled, highly resilient texture. Conversely, using a balanced combination of S and Z twists ensures the finished material lies flat, resists skewing during finishing, and maximizes the performance benefits of twisted yarn fabric without introducing unwanted structural tension. Understanding this allows manufacturers to manipulate the finished material's hand and drape with precision.

Does the twist level in the yarn affect the cost of the finished fabric?

Yes, the twist level in the yarn is a significant factor in the cost of the finished Twisted Yarn Fabric. Yarn twisting is a secondary manufacturing process that requires dedicated machinery (twisting frames) and additional production time and energy, all of which add to the operational cost. Fabrics made with high-twist yarns, such as those used for fine worsted wool or high-end crepe, generally command a higher price because they require more passes through the twisting machine, increasing the processing complexity and decreasing the production yield. Furthermore, the highest quality twisted yarns are often made from superior, longer-staple fibers that can withstand the twisting stress without breaking, which also contributes to a higher raw material cost. Consumers seeking the enhanced durability, pilling resistance, and superior hand-feel associated with twisted yarn fabric for clothing durability should expect a premium price that reflects the complex engineering and extended life cycle of the material. This cost is a direct reflection of the added quality and performance built into the yarn structure.

Can twisted yarn fabric be made from synthetic fibers, and how does the twisting process differ?

Absolutely, twisted yarn fabric can be, and frequently is, made from synthetic fibers such as polyester, nylon, and rayon. The fundamental principles of twisting remain the same—introducing a controlled amount of twist to increase cohesion, strength, and durability. However, the twisting process for synthetics often differs in key ways due to the nature of the material. Synthetic filament yarns (long, continuous strands) are typically twisted differently than natural staple (short) fibers. For filament yarns, the process is often called ‘texturizing’ or ‘false-twist texturing,’ which rapidly imparts and then heat-sets a crimp or twist into the yarn. This heat-setting is critical for synthetics, as it permanently locks the molecular structure in the twisted position, ensuring the yarn maintains its stability and bulk after processing and washing, which directly impacts the long-term care instructions for twisted yarn fabric. The ability to precisely control the twist and use heat-setting technology allows synthetic twisted yarn fabric to achieve exceptional resilience, elasticity, and specific performance characteristics required for technical textiles, performance wear, and industrial applications.

English

English русский

русский عربى

عربى