The Art and Science of Twisted Yarns: A Comprehensive Guide

2025-12-19

The Foundational Role of Twisted Yarns in Modern Textiles

The journey of any fabric begins long before it reaches the loom, rooted in the fundamental process of twisting fibers into yarn. Twisted yarns are the unsung heroes of the textile world, providing the essential strength, texture, and performance characteristics that define the final material. For over two decades, our family-owned manufacturing operation has specialized in transforming raw filaments into high-performance polyester nylon fabrics and elegant silks, with our 100 matching twisters playing a pivotal role in this transformation. The twist is not merely a mechanical step; it is a critical engineering decision that influences a fabric's durability, hand feel, elasticity, and aesthetic appeal. From the rugged demands of outdoor functional clothing to the delicate drape of women's silk lines and the structured resilience of jacquard luggage fabrics, the creation and application of twisted yarns are central to achieving desired outcomes. This article delves into the intricate world of yarn twisting, exploring techniques, applications, and how this core process shapes the fabrics that surround us every day.

Exploring Key Techniques and Applications

To truly understand the versatility of twisted yarns, we must explore specific techniques and end-uses where they make a defining difference. The following sections are structured around five key long-tail concepts that highlight niche areas with significant practical interest for designers, manufacturers, and enthusiasts. These concepts are: twisted yarns for durable outdoor gear fabric, how to fix uneven twist in handspun yarn, best twisted yarn for silk scarf weaving, high twist vs low twist yarn strength comparison, and twisted cotton yarn for heavyweight jacquard. Each of these topics addresses a unique challenge or application, providing a roadmap for selecting and working with the right twisted yarn.

Crafting Resilience: Twisted Yarns for Demanding Environments

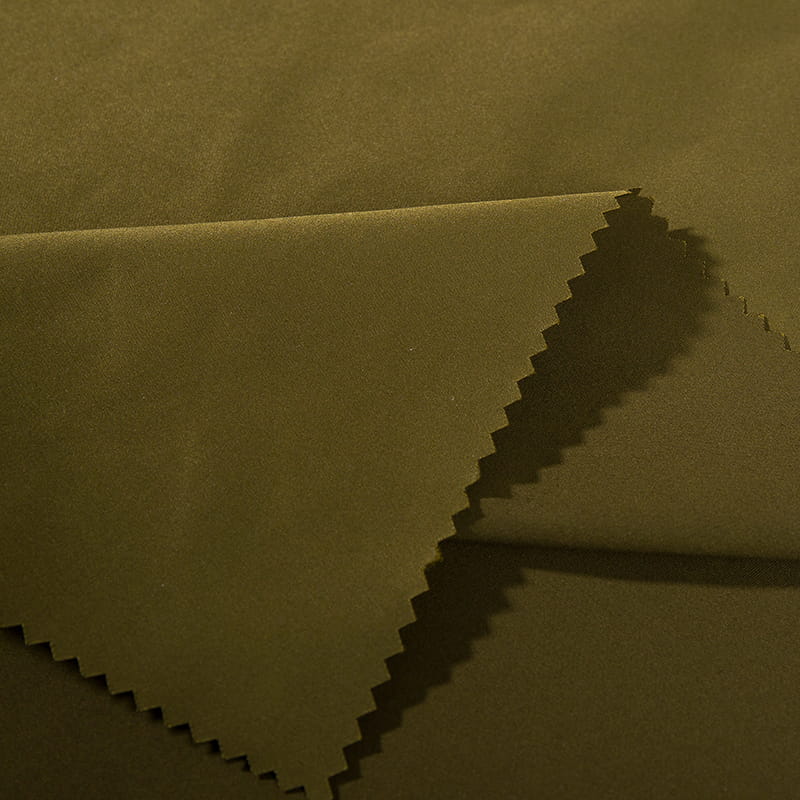

The application of twisted yarns for durable outdoor gear fabric represents one of the most technically demanding areas in textile production. Outdoor functional clothing and equipment—from hiking pants and reinforced backpack straps to tent shells and tactical gear—require fabrics that can withstand abrasion, moisture, UV exposure, and repeated stress. The secret to this resilience often lies in the yarn construction. In our production of polyester nylon fabrics, we employ specific high-twist techniques that bind the synthetic filaments tightly together. This process enhances the tensile strength of the individual yarn and reduces the tendency for fibers to pull apart or pill during use. Furthermore, a tightly twisted yarn creates a denser weave structure, improving the fabric's wind resistance and, when combined with appropriate finishing processes, its water repellency. The durability is not just about raw strength; it's about consistency. With 300 self-owned water jet looms and integrated twisters, we ensure that every meter of fabric benefits from a uniform, high-performance yarn base, which is crucial for brands that cannot afford batch inconsistencies in their outdoor product lines. This integrated control from twisting to weaving is what allows for the cost-effective production of reliable, high-specification outdoor fabrics.

Mastering the Craft: Solutions for Handspinning Challenges

While industrial production focuses on uniformity, the artisanal world of handspinning embraces character, which sometimes includes imperfections. A common hurdle for spinners is how to fix uneven twist in handspun yarn. Uneven twist can manifest as slubs (overly thick, lightly twisted sections) or thin, over-twisted sections, leading to a yarn that plies inconsistently and knits or weaves into a fabric with poor hand feel and irregular strength. Fixing this issue requires both preventative techniques and corrective measures. Prevention starts at the wheel: maintaining a consistent treadle rhythm, careful control of fiber feed (drafting), and ensuring the fiber preparation (carding or combing) is uniform. For yarn that has already been spun, several methods can help redistribute or correct the twist. One effective technique is to steam the skein gently under tension; the moisture and heat can allow the fibers to relax slightly, letting excess twist migrate from over-twisted areas into under-twisted ones. Another method is to re-spin the yarn, either by running it through the wheel again to add twist where needed or, in severe cases, by re-drafting and re-spinning the most inconsistent sections. The goal is to achieve a balanced yarn where the twist energy is stabilized, resulting in a more professional and durable handspun product suitable for sophisticated projects.

Elegance in Detail: Selecting Yarns for Luxurious Accessories

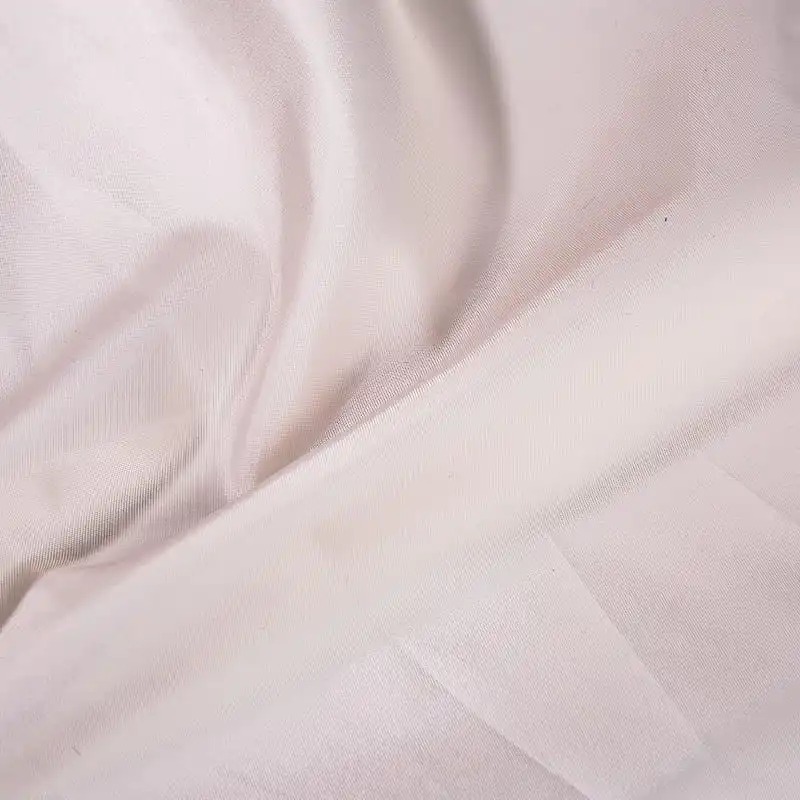

The creation of a luxurious silk scarf is an exercise in balancing beauty and functionality, and the choice of yarn is paramount. When considering the best twisted yarn for silk scarf weaving, several factors come into play: sheen, drape, strength, and the final texture of the woven cloth. Silk, a natural protein fiber, possesses a natural luster and strength. For scarves, yarns are often made from mulberry silk, known for its fine, regular filaments. The twist level is crucial. A very low twist or no twist (a filament silk) will yield a fabric with maximum shine and a fluid, slippery drape, but it may be prone to snagging and can feel almost too cool against the skin. A medium to high twist, however, creates a different character. A twisted silk yarn, sometimes called "crepe" twist, introduces a subtle texture, reduces the extreme slickness, and improves the fabric's resilience and wrinkle resistance. It also allows the silk to better absorb dyes, resulting in rich, vibrant colors. For a lightweight, gauzy scarf, a finely spun, high-twist yarn woven in an open sett is ideal. For a warmer, winter-weight scarf, a plied silk yarn—where multiple twisted strands are twisted together—provides loft, warmth, and a beautiful matte or pebbled texture. The decision ultimately hinges on the desired aesthetic and tactile experience.

The Core Mechanic: Analyzing Twist Direction and Intensity

A fundamental understanding of yarn performance comes from a high twist vs low twist yarn strength comparison. The twist level, measured in twists per inch (TPI) or turns per meter (TPM), is a primary determinant of a yarn's properties. It's not a matter of which is universally "better," but which is more appropriate for the intended application.

To illustrate the key differences, consider the following comparison:

| Characteristic | High-Twist Yarn | Low-Twist Yarn |

|---|---|---|

| Inherent Strength | Higher. The tight helical structure binds fibers together, increasing cohesion and resistance to pulling apart under tension. | Lower. Fibers are more loosely associated, making the yarn more susceptible to breakage under direct load. |

| Surface Texture | Harder, crisper, and can have a wiry hand. Often used for crepe fabrics, tire cord, and durable outerwear. | Softer, loftier, and has a more fuzzy or hairy surface. Ideal for brushed fabrics, cozy knits, and materials where softness is key. |

| Drape and Flexibility | Can produce a fabric with more body and structure, but may be less fluid depending on fiber type. | Typically results in a fabric with excellent, fluid drape and more inherent flexibility. |

| Absorbency and Dye Take-Up | The compact structure can slow liquid absorption but can lead to vibrant, sharp dye results as dye concentrates on the surface. | More absorbent due to air spaces between fibers. May produce a softer, more muted color effect. |

| Common Applications | Seaming threads, performance outdoor fabrics, crepe de chine, gabardine. | Weft yarns for comfort, looped or terry fabrics, malimo stitches, some lining materials for bulk. |

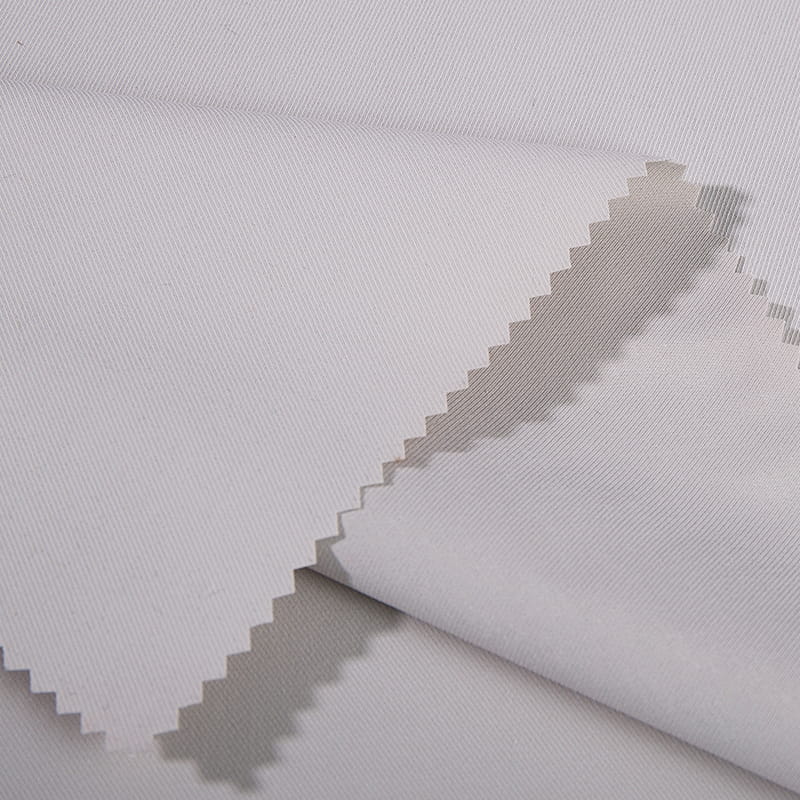

In our factory's context, producing lining fabrics often involves lower twist yarns for comfort, while our outdoor functional fabrics utilize higher twist yarns for abrasion resistance. Understanding this spectrum allows designers to engineer fabric performance from the yarn up.

Building Structure and Design in Decorative Fabrics

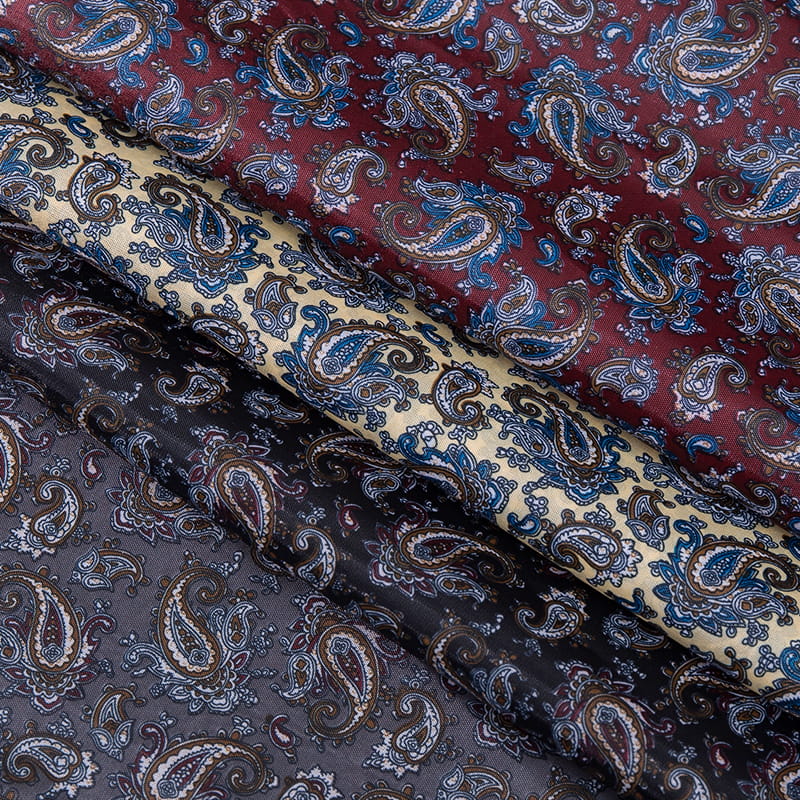

Jacquard weaving allows for intricate, large-scale patterns, but these complex designs demand a yarn that can provide clear definition and structural integrity. This is where twisted cotton yarn for heavyweight jacquard becomes a material of choice. Cotton, a staple fiber, requires twist to hold its short fibers together and create a continuous thread. For heavyweight jacquard fabrics used in luggage, upholstery, or decorative wall coverings, the yarn specifications are critical. A firmly twisted, plied cotton yarn offers several advantages. Firstly, the ply (twisting multiple single yarns together) creates a rounder, stronger, and more uniform yarn that weaves cleanly, preventing breakage on the loom under high tension—a key concern with complex jacquard mechanisms. Secondly, the twist gives the yarn enough rigidity to hold the precise shapes of the jacquard pattern without blurring, resulting in crisp, well-defined motifs. The weight and heft come from both the yarn thickness (count) and the dense weave structure enabled by such a stable yarn. Our experience in producing jacquard luggage fabrics relies on sourcing and creating these robust twisted cotton yarns, which provide the perfect substrate for durable, high-clarity patterns that must endure physical stress while maintaining their visual appeal.

Integrating Expertise from Fiber to Finished Fabric

The journey of a twisted yarn from a concept to a component in a finished textile product encapsulates the entire textile manufacturing value chain. It begins with fiber selection—whether synthetic filaments for strength or natural staples for comfort—and proceeds through the precise engineering of the twisting process. The five long-tail concepts explored here demonstrate that there is no one-size-fits-all approach. The optimal twist for a delicate silk scarf is fundamentally different from that required for a mountaineering backpack. This specialized knowledge is what defines expert manufacturing. Our operational philosophy, built over 20 years, is to integrate these stages. Controlling the twisting process in-house with dedicated machinery allows for immediate feedback loops between weaving trials and yarn adjustments, ensuring that the final fabric meets exact specifications for performance, aesthetics, and cost. Furthermore, this integration is the foundation of our ability to accept and execute on custom samples from global clients efficiently. Whether a designer seeks a novel texture, a specific performance attribute, or a unique aesthetic for their line, the conversation often starts at the yarn level. Understanding the profound impact of twisted yarns empowers brands to make informed decisions, leading to innovative and successful textile products that stand the test of time and trend.

English

English русский

русский عربى

عربى