Polyester Nylon Fabrics: Advanced Performance, Structure, and Industrial Applications

2025-12-22

Understanding Polyester Nylon Fabrics

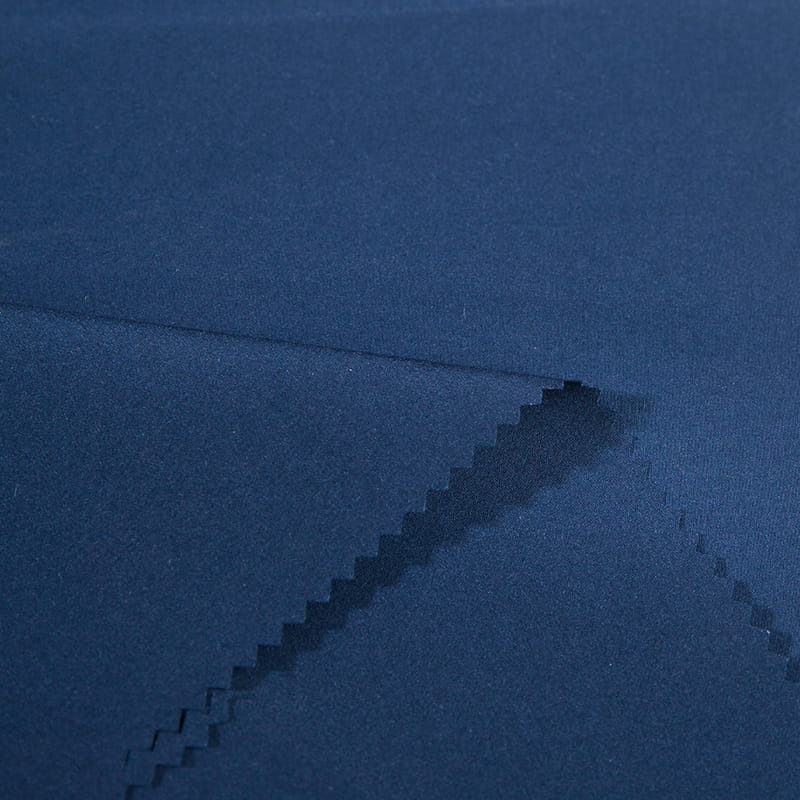

Definition and Fabric Structure

- Polyester Nylon Fabrics are engineered textiles made by blending polyester and nylon filaments

- The blend ratio is adjusted to balance strength, flexibility, and dimensional stability

- These fabrics are widely used in applications where durability and lightweight performance are both required

Fiber Interaction Within the Fabric

- Polyester fibers provide structural stability and resistance to deformation

- Nylon fibers contribute elasticity and abrasion resistance

- The interlacing of both fibers enhances long-term fabric reliability

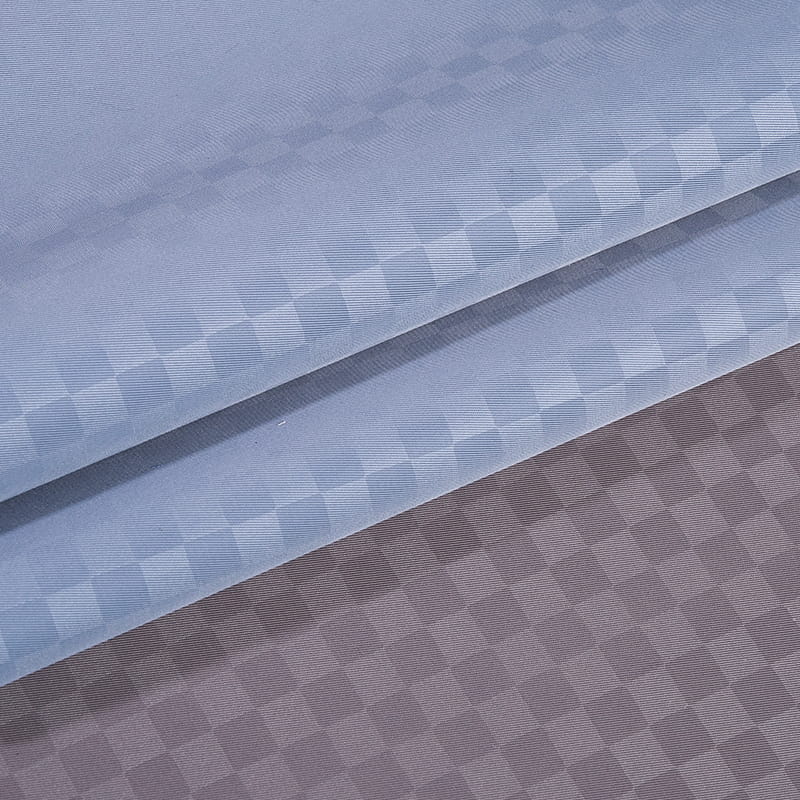

Material Characteristics of Polyester Nylon Fabrics

Physical Performance Attributes

- High tensile strength suitable for repeated stress environments

- Controlled elongation to prevent permanent deformation

- Balanced hand feel for comfort-focused textile applications

Chemical and Environmental Stability

- Polyester improves resistance to moisture absorption

- Nylon enhances resistance to friction and surface wear

- Blended structure performs well under finishing and dyeing processes

Performance Explanation Before Comparison

Compared to single-fiber fabrics, blended polyester nylon fabrics demonstrate a more balanced performance profile. They avoid excessive rigidity found in pure polyester and excessive flexibility seen in pure nylon.

| Performance Factor | Polyester Nylon Fabrics | Polyester Fabric | Nylon Fabric |

| Tear Resistance | High and stable | Medium | Very high |

| Dimensional Stability | Excellent | Excellent | Moderate |

| Abrasion Resistance | High | Medium | Very high |

| Fabric Balance | Optimized | Rigid | Elastic |

Application Analysis of Polyester Nylon Fabrics

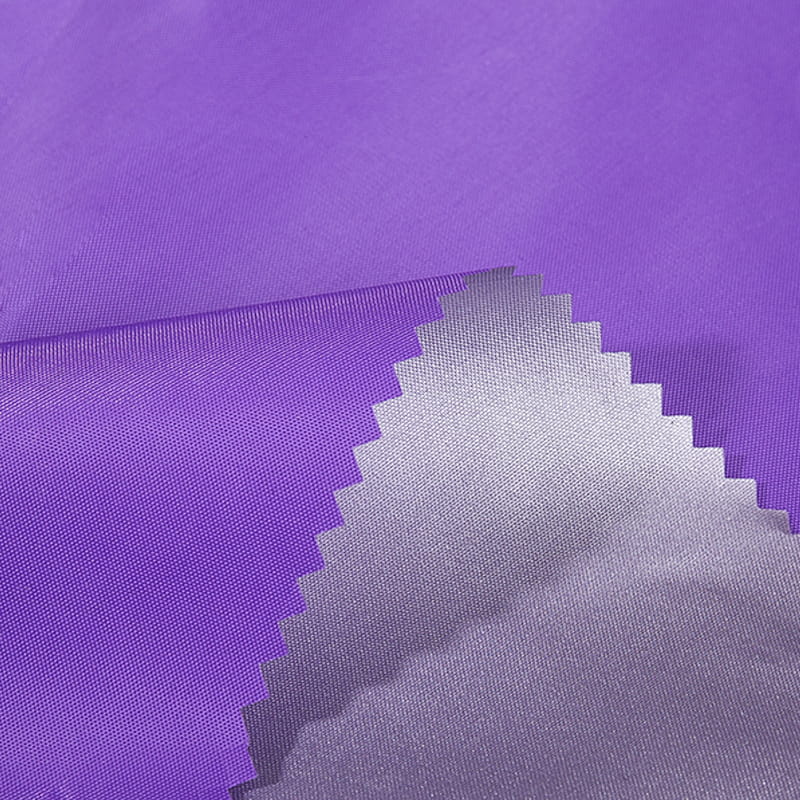

Outdoor and Functional Apparel

- Widely used as polyester nylon fabrics for outdoor clothing

- Provides protection without excessive fabric weight

- Supports functional finishing such as coating and lamination

Garment-Level Benefits

- Improved garment shape retention after repeated use

- Reduced surface damage caused by friction

- Comfortable inner structure when used in layered systems

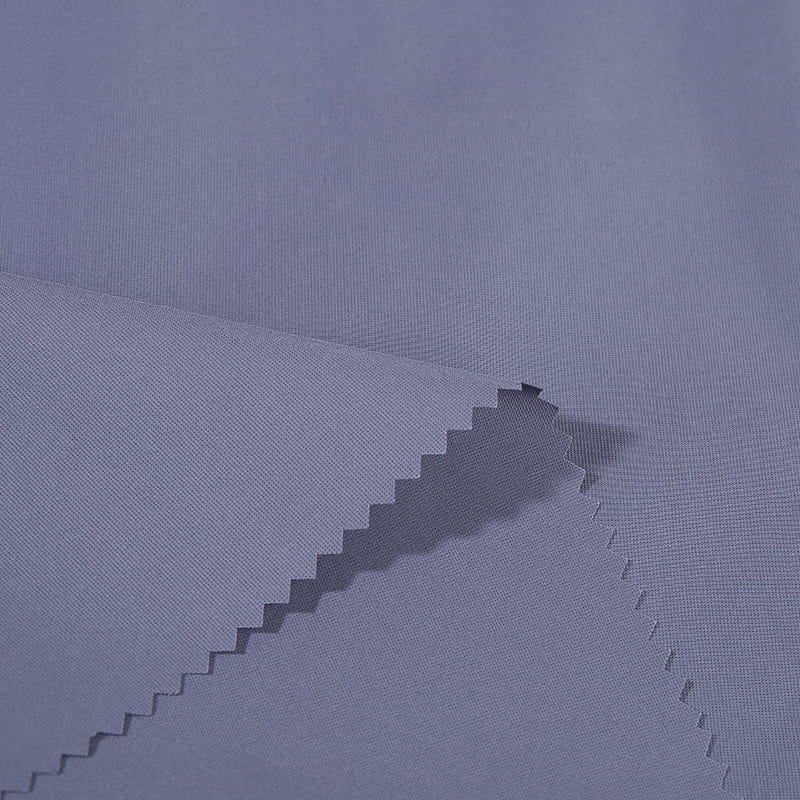

Lining and Interior Fabric Applications

- Frequently supplied by polyester nylon lining fabric manufacturer operations

- Acts as a structural and protective internal layer

- Enhances durability of finished garments and products

Bags, Luggage, and Load-Bearing Goods

- Optimized as lightweight polyester nylon fabric for bags

- Suitable for jacquard weaving and reinforced patterns

- Maintains strength while minimizing overall product weight

Manufacturing Capabilities and Production Control

Equipment Scale and Output Stability

- 300 self-owned water jet looms ensure consistent weaving capacity

- 100 twisters enable controlled yarn preparation

- Equipment ownership guarantees production scheduling reliability

Process Control and Fabric Consistency

- Precise tension control during weaving

- Stable finishing conditions for uniform performance

- Continuous monitoring across production batches

| Production Aspect | In-House Manufacturing | Outsourced Production |

| Quality Stability | High | Variable |

| Delivery Speed | Fast and predictable | Uncertain |

| Customization Flexibility | Strong | Limited |

Customization and Product Development Support

Custom Fabric Development

- Operates as a custom polyester nylon fabric factory in China

- Accepts detailed technical requirements from international clients

- Supports sampling and specification adjustment

Functional Wear Fabric Design

- Designed for durable polyester nylon fabric for functional wear

- Meets durability standards for repeated movement

- Balances mechanical performance with comfort

Experience, Reliability, and Long-Term Cooperation

Manufacturing Experience

- Family-owned plant with over 20 years of operation

- Specialized focus on polyester nylon fabrics and linings

- Deep understanding of textile production and finishing processes

Supply Chain Confidence

- Stable output capacity ensures reliable delivery schedules

- Cost-effective solutions under quality assurance conditions

- Open to factory visits in China for international partners

Frequently Asked Questions

What are the main advantages of polyester nylon fabrics?

They provide balanced durability, stability, and lightweight performance.

Are polyester nylon fabrics suitable for outdoor use?

Yes, they are commonly used in outdoor and functional clothing applications.

Can polyester nylon fabrics be customized?

Custom samples and specifications are accepted for different applications.

How is fabric consistency ensured?

Through in-house equipment and controlled production processes.

What products commonly use polyester nylon fabrics?

Outdoor apparel, linings, luggage fabrics, and functional goods.

English

English русский

русский عربى

عربى