The Complete Guide to Imitated Silk Fabric: Elegance, Performance, and Production

2026-01-02

In the world of textiles, the quest for the perfect blend of luxury, functionality, and affordability is never-ending. Imitated silk fabric has emerged as a revolutionary solution, offering the coveted drape and sheen of natural silk without its inherent fragility and high cost. This guide delves deep into the nuances of imitated silk, exploring its benefits, varieties, and the advanced manufacturing that makes it an ideal choice for modern fashion and functional applications. For businesses seeking reliable, high-volume production, partnering with an experienced manufacturer is key to unlocking its full potential.

What is Imitated Silk Fabric?

Imitated silk, often referred to as artificial or synthetic silk, is a man-made textile engineered to replicate the aesthetic qualities of natural silk. Unlike silk derived from silkworms, imitated silk is typically produced from synthetic fibers like polyester or nylon, or sometimes from regenerated fibers like rayon. The magic lies in the sophisticated production and finishing processes that transform these durable, cost-effective fibers into fabrics with a soft hand feel, luminous appearance, and beautiful drape. This makes imitated silk fabric a versatile hero material across diverse industries.

5 Key Advantages of Choosing Imitated Silk

The rise of imitated silk is no accident. It addresses specific pain points associated with natural silk while adding unique performance benefits.

Durability and Strength

- Superior Resilience: Polyester and nylon-based imitated silk are inherently stronger than natural silk fibers, making them resistant to tearing and abrasion.

- Longevity: Garments and products made from imitated silk maintain their integrity and appearance far longer, even with frequent use.

- Less Delicate: It does not weaken when wet, unlike natural silk, and is less prone to damage during manufacturing and everyday wear.

Cost-Effectiveness and Accessibility

- Reduced Material Costs: The production of synthetic fibers is less resource-intensive than sericulture (silk farming), leading to significantly lower prices.

- Democratizing Luxury: This affordability allows designers and brands to incorporate a silk-like aesthetic into more product lines, from fast fashion to luxury accessories.

- Stable Pricing: Unlike natural silk, whose price can fluctuate with harvests, imitated silk offers predictable and stable costing for bulk production.

Ease of Care and Maintenance

- Wrinkle Resistance: Many imitated silk fabrics, especially those with a polyester base, are highly wrinkle-resistant, reducing the need for ironing.

- Machine Washable: Most varieties can be safely machine-washed on gentle cycles, whereas natural silk often requires dry cleaning.

- Quick Drying: Synthetic fibers have low water absorption, allowing items to dry much faster after washing.

Versatility in Design and Application

- Wide Finishing Range: It can be finished with coatings for water resistance, laminated for structure, or printed with intricate patterns with high clarity.

- Cross-Industry Use: Its application seamlessly spans women's silk lines for blouses and dresses, luxurious jacquard luggage fabrics, and elegant linings for formal and outdoor wear.

Consistency and Ethical Production

- Uniform Quality: Machine production ensures every meter of fabric has consistent color, weight, and texture, which is challenging with natural silk.

- Animal-Free: As a vegan alternative, it appeals to a growing market of ethically-conscious consumers.

- Controlled Process: The entire manufacturing, from fiber extrusion to finishing, occurs in a controlled industrial setting, ensuring high standards.

Exploring Popular Types and Their Best Uses

Not all imitated silk is created equal. Different weaves and finishes create fabrics suited for specific purposes. Understanding the properties of polyester satin fabric versus other types is crucial for selecting the right material.

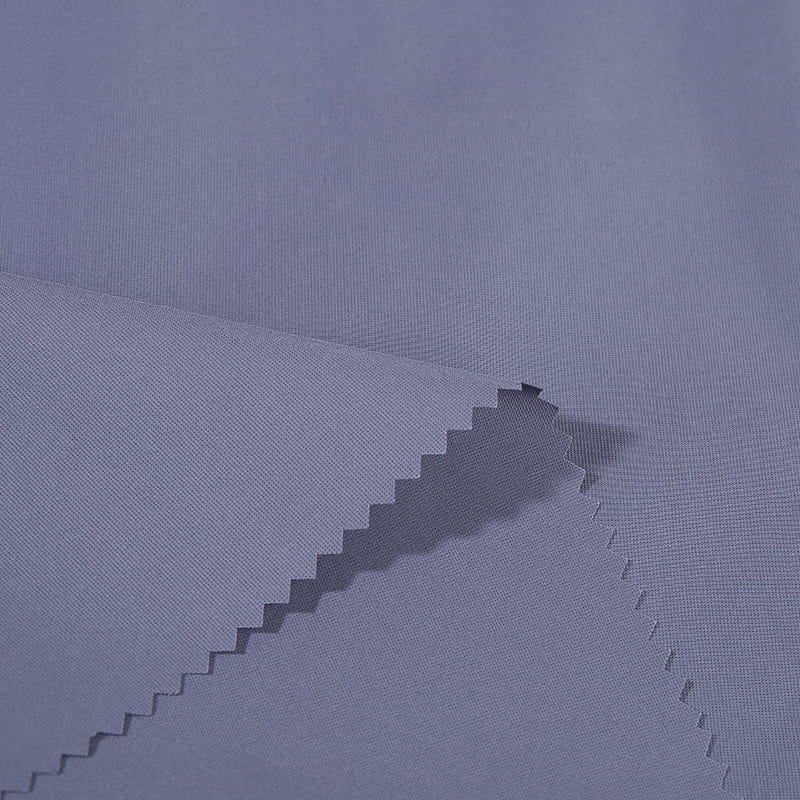

Polyester Satin

This is the most common type of imitated silk. The satin weave structure gives it a characteristically smooth, glossy surface on one side and a dull back.

- Key Characteristics: High sheen, excellent drape, relatively heavy weight.

- Ideal For: Evening gowns, lingerie, luxurious lining material for jackets, and premium accessory bags.

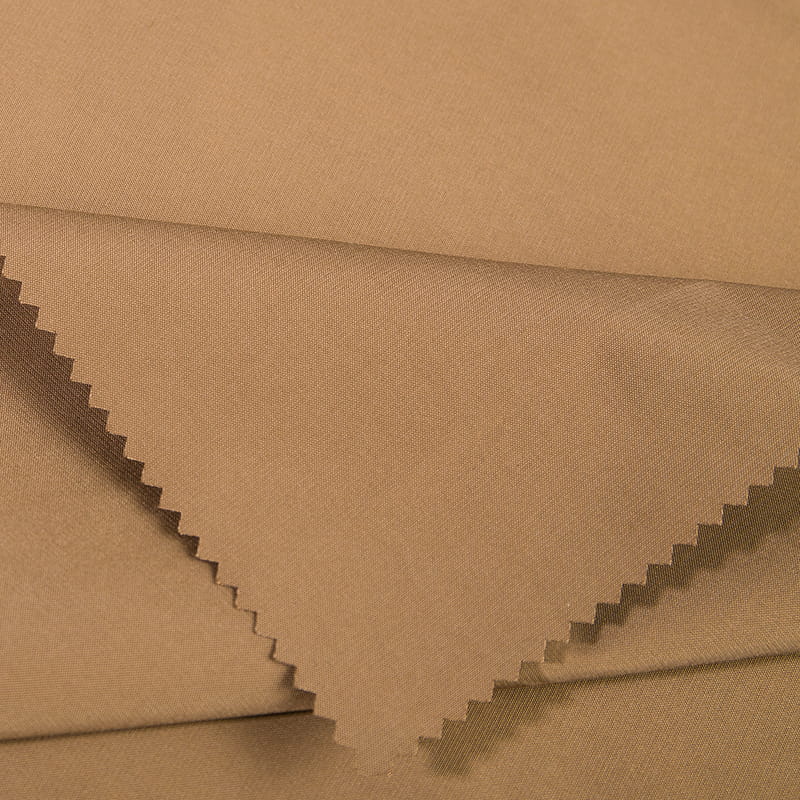

Polyester Charmeuse

A lighter, more fluid version of satin, charmeuse has a glossy front and a matte back. It is exceptionally soft and drapes beautifully.

- Key Characteristics: Lightweight, fluid drape, luxurious hand feel.

- Ideal For: Flowing dresses, blouses, scarves, and delicate women's silk lines where movement is key.

Nylon-Based Imitated Silk

Nylon variants offer exceptional strength and resilience, often used in more demanding applications.

- Key Characteristics: High tensile strength, excellent abrasion resistance, good elasticity.

- Ideal For: Activewear linings, durable luggage interiors, and technical linings for outdoor gear where performance is critical.

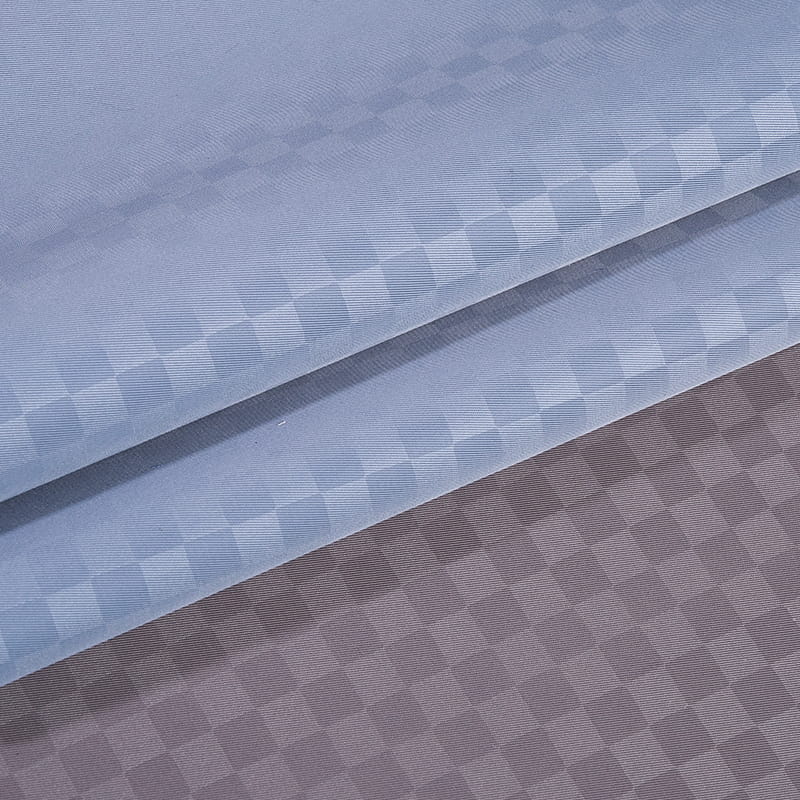

Jacquard Woven Imitated Silk

This involves using a jacquard loom to create intricate, raised patterns directly into the fabric, adding texture and depth.

- Key Characteristics: Ornate patterns, textured surface, rich visual appeal.

- Ideal For: High-end jacquard luggage fabrics, upholstery, theatrical costumes, and statement fashion pieces.

Imitated Silk vs. Natural Silk: A Detailed Comparison

Choosing between imitated and natural silk depends heavily on the project's requirements. The following table breaks down the key differences to inform your decision. This comparison highlights why understanding the difference between satin and real silk is fundamental for designers and manufacturers.

| Feature | Imitated Silk (e.g., Polyester Satin) | Natural Silk |

|---|---|---|

| Fiber Origin | Chemically synthesized polymers (Polyester, Nylon) | Natural protein fiber from silkworms |

| Cost | Generally low to moderate; highly cost-effective for bulk | Very high due to labor-intensive production |

| Durability | Very high; resistant to tearing, abrasion, and sunlight | Moderate; strong but can be damaged by sun, sweat, and improper care |

| Care & Maintenance | Easy; often machine washable, wrinkle-resistant, quick-drying | Delicate; usually requires hand washing or dry cleaning, prone to wrinkling |

| Environmental Impact | Derived from petrochemicals; recycling is possible but energy-intensive to produce | Biodegradable and renewable, but large-scale sericulture can have water/land use impacts |

| Moisture Management | Low absorption; can feel less breathable in some weaves | High absorption; naturally temperature-regulating and breathable |

| Aesthetic & Hand Feel | Consistently smooth and shiny; can feel slightly less "organic" | Uniquely luminous with a distinctive, supremely soft hand feel |

The sentence-form comparison is as follows: Imitated silk is significantly more durable and easier to care for than natural silk, while natural silk offers superior breathability and a unique, organic hand feel that is difficult to replicate perfectly. The cost difference between the two is substantial, making imitated silk the practical choice for high-volume or performance-oriented projects.

Critical Manufacturing Processes: From Fiber to Fabric

The quality of imitated silk fabric is directly tied to the expertise and technology behind its production. As a family-owned plant with over two decades of specialization in synthetic fabrics, we understand that mastery of these processes is what transforms raw polymer into a luxurious textile.

Fiber Extrusion and Yarn Preparation

- Polymer Chips: The journey begins with PET (for polyester) or PA (for nylon) chips.

- Melt Spinning: Chips are melted and extruded through a spinneret to form continuous filaments.

- Drawing & Twisting: Filaments are drawn to align polymers, increasing strength. Using 100 matching twisters, we can create yarns with specific textures and strengths suitable for everything from fine linings to sturdy jacquards.

Weaving on Advanced Looms

- Loom Technology: Our 300 self-owned water jet looms offer high-speed, efficient production with minimal tension on the yarns.

- Weave Selection: The desired finish dictates the weave—satin for gloss, plain for versatility, or jacquard for complexity.

- Precision: Modern looms ensure tight, consistent weave density, which is crucial for achieving a smooth, defect-free surface that mimics silk.

Dyeing and Finishing: Where Magic Happens

This stage is arguably the most important for achieving the silk-like quality. It's where we answer the question of how to care for synthetic silk fabrics by building in performance features from the start.

- Dyeing: Fabrics are dyed using methods that ensure color fastness and vibrancy. For instance, the best dyeing methods for colorfast silk-like textiles often involve high-temperature, pressurized jet dyeing for even penetration and lasting results.

- Calendering: The fabric passes through heated rollers under pressure, which flattens the fibers and enhances the glossy surface.

- Chemical Finishing: Special softeners, anti-static agents, and durable water repellent (DWR) coatings can be applied. This is essential for creating technical linings for outdoor gear that require moisture management.

- Quality Control: Every batch undergoes rigorous inspection for consistency in color, weight, width, and visual defects, ensuring the final product meets stringent standards.

Frequently Asked Questions (FAQ)

1. Is imitated silk fabric breathable?

Breathability varies with the fiber and weave. While it generally doesn't match the natural temperature regulation of real silk, advancements in microfiber polyester and specific weave structures can improve moisture-wicking and airflow. For high-breathability applications, discussing specifications with your manufacturer is key.

2. How do I properly wash and care for imitated silk items?

Most imitated silk is low-maintenance. For how to care for synthetic silk fabrics, we recommend machine washing on a cold, gentle cycle with mild detergent. Tumble dry on low heat or, ideally, hang to dry. Always check the care label, as some specialty finishes may have specific requirements.

3. Can imitated silk be used for outdoor or technical clothing?

Absolutely. When treated with appropriate finishes, it becomes an excellent technical linings for outdoor gear. Nylon-based imitated silk offers durability, while PU laminations or DWR treatments can provide wind and water resistance, making it ideal for lining jackets, gloves, and sleeping bags.

4. How does the environmental impact of imitated silk compare to real silk?

This is a complex issue. Natural silk is biodegradable but resource-intensive in farming. Imitated silk, derived from petrochemicals, has a higher initial carbon footprint and is not biodegradable, but its durability and potential for recycling (from PET bottles, for example) can mitigate its lifecycle impact. The industry is actively working on more sustainable synthetic fibers[1].

5. Why is imitated silk a good choice for luggage and bag linings?

Its strength, abrasion resistance, and smooth surface make it the best lining material for luggage. It protects clothing from snagging on zippers or seams, is easy to clean, and the glossy finish adds a touch of luxury and visibility inside a bag. Jacquard woven versions further enhance aesthetic appeal for high-end luggage lines.

Conclusion: The Smart Choice for Modern Manufacturing

Imitated silk fabric represents the perfect synergy of aesthetic desire and practical necessity. It delivers the opulent look and feel of silk while overcoming its limitations in durability, cost, and care. For businesses in fashion, luggage, and outdoor goods, it offers a reliable, versatile, and cost-effective material that can be customized to exact needs. Success hinges on partnering with a manufacturer that possesses deep technical expertise in fiber science, weaving, and finishing processes. A partner with substantial in-house production capacity, like our family-operated facility with 300 looms and decades of experience, ensures not only quality and customization but also the rapid, scalable delivery required in today's fast-paced market. From developing custom samples to executing bulk orders with precision, the right manufacturing partnership turns the potential of imitated silk into a tangible competitive advantage.

References

[1] Textile Exchange. (2023). *Preferred Fiber & Materials Market Report*. Retrieved from https://textileexchange.org/app/uploads/2023/10/Textile-Exchange_PFMR_2023.pdf (This source discusses the environmental landscape of synthetic and natural fibers, including lifecycle impacts and innovations in sustainable alternatives.)

English

English русский

русский عربى

عربى