The Complete Guide to Imitated Silk Fabric: Production, Properties, and Applications

2026-01-08

For over two decades, our family-owned textile mill has specialized in creating high-performance and aesthetically pleasing fabrics. With deep expertise in polyester, nylon, and lining production, we understand the intricate balance between cost, quality, and delivery. The emergence of imitated silk fabric represents a fascinating convergence of these values—offering the luxurious drape and sheen of silk with enhanced durability and practicality. This guide delves into the world of imitated silk, exploring its manufacturing, benefits, and ideal uses for businesses seeking sophisticated yet functional material solutions.

What is Imitated Silk Fabric?

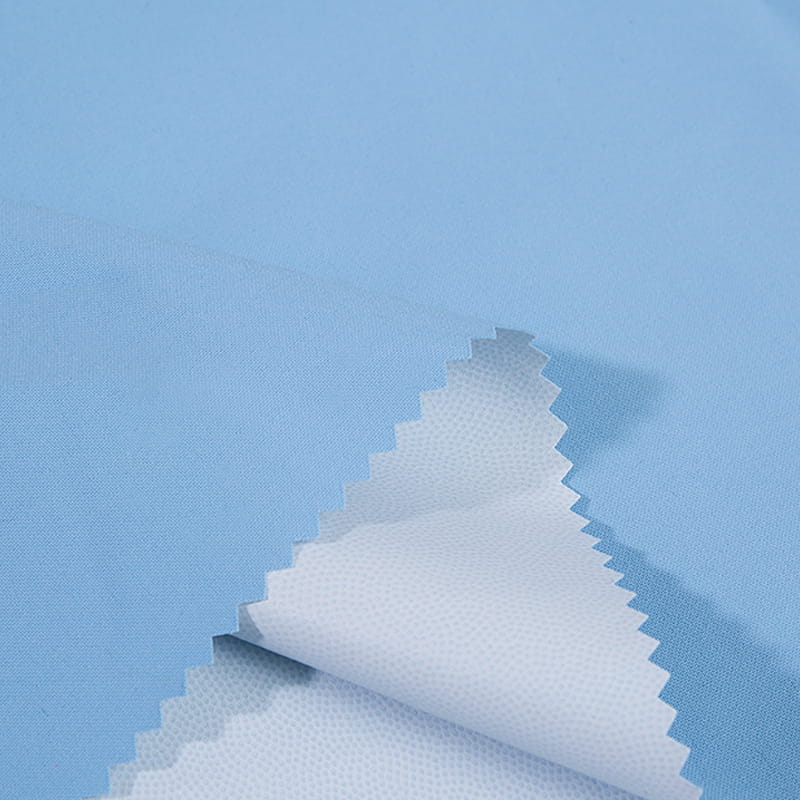

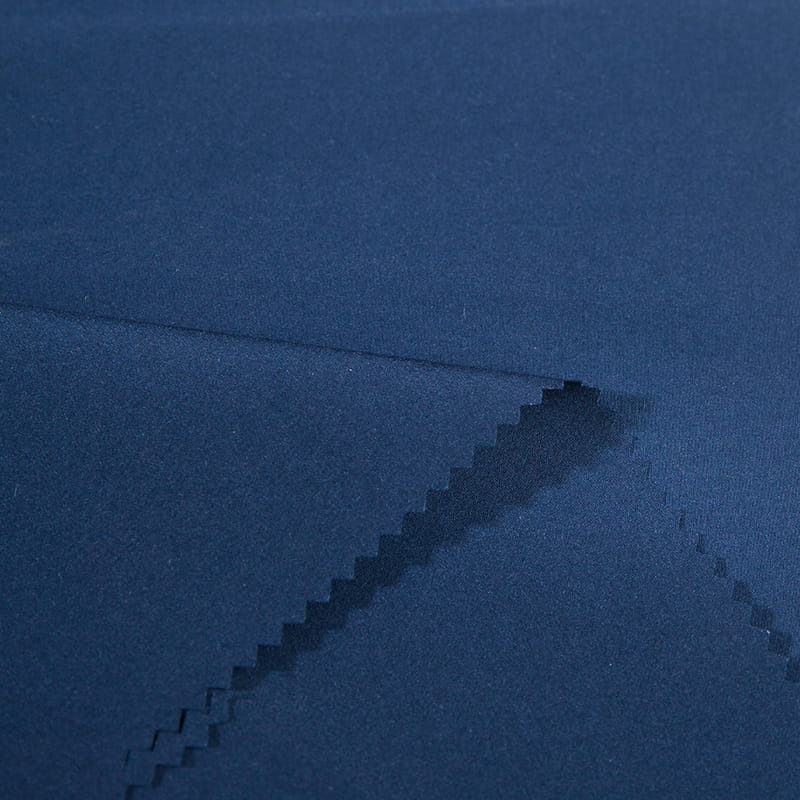

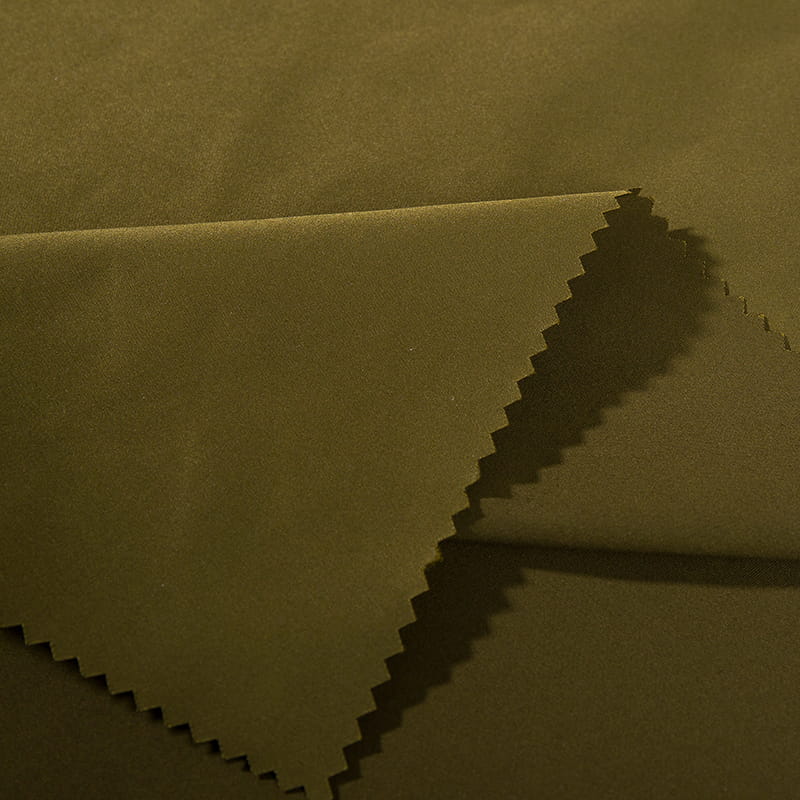

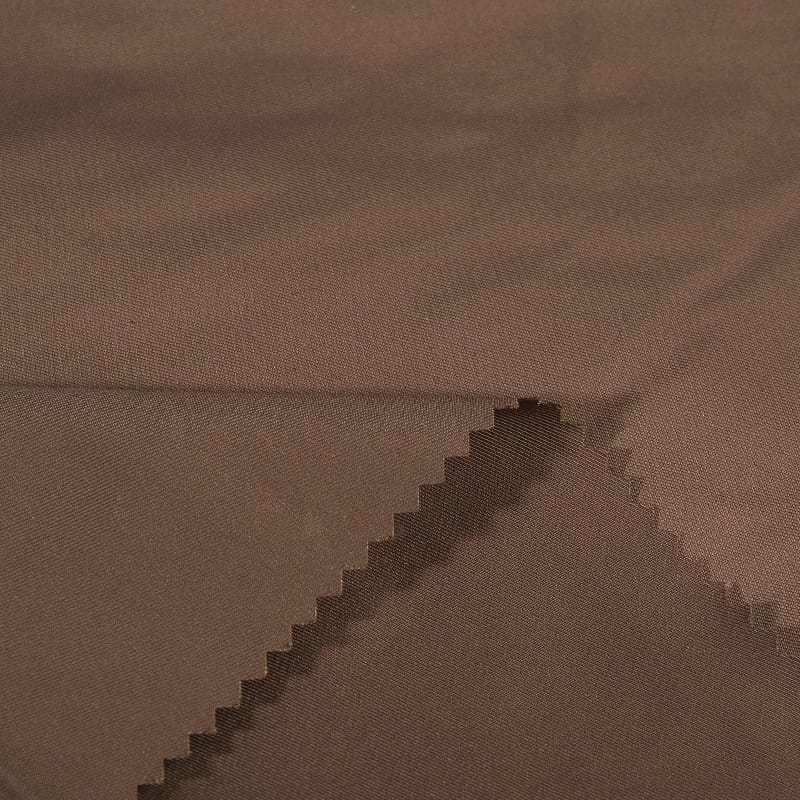

Imitated silk fabric, often known as artificial or faux silk, is a synthetic textile engineered to mimic the visual and tactile qualities of natural silk. Primarily woven from continuous filament fibers like polyester, it replicates the characteristic luster, smooth handle, and fluid drape of its natural counterpart. The advancement in textile finishing technologies allows manufacturers to impart a remarkably silk-like feel and appearance, making it a versatile and cost-effective alternative for a wide array of applications, from fashion to home furnishings.

Primary Composition and Manufacturing

- Base Fiber: Polyester is the predominant fiber due to its strength, dye affinity, and ability to be finely woven into smooth filaments.

- Weaving Technique: Typically produced using high-density water jet looms, which create a tight, seamless fabric surface that enhances the silk-like sheen.

- Finishing Processes: Crucial steps like calendaring (heat pressing), softening, and optical brightening are applied to achieve the desired softness, drape, and luminous quality.

Key Advantages of Choosing Imitated Silk

The decision to use imitated silk fabric over natural silk is driven by several compelling practical and economic benefits that align with modern manufacturing and consumer needs.

Durability and Care

- Enhanced Strength: Polyester-based imitated silk boasts superior tensile strength and abrasion resistance compared to delicate natural silk.

- Wrinkle Resistance: It holds its shape well and is less prone to creasing, reducing maintenance effort.

- Easy Maintenance: Most variants are machine washable and dry quickly, unlike natural silk which often requires dry cleaning.

Cost-Effectiveness and Consistency

- Lower Production Cost: The use of synthetic fibers and efficient, large-scale production methods makes it significantly more affordable.

- Batch-to-Batch Uniformity: Synthetic production ensures consistent color, weight, and texture, which is crucial for large orders.

- Accessibility: It provides a luxurious aesthetic at a fraction of the price, expanding design possibilities for various product lines.

Imitated Silk vs. Natural Silk: A Detailed Comparison

Understanding the distinct differences between imitated and natural silk is key to selecting the right fabric for your project. The following table breaks down their core characteristics.

| Property | Imitated Silk (Polyester-based) | Natural Silk |

| Fiber Origin | Synthetic (Petrochemical) | Natural (Silkworm Cocoon) |

| Cost | Low to Moderate | Very High |

| Durability & Strength | High; excellent abrasion resistance | Moderate; can be delicate and prone to snagging |

| Care Requirements | Easy; often machine washable | Demanding; usually requires hand wash or dry cleaning |

| Moisture Absorption | Low | High (Breathable) |

| Environmental Impact | Derived from non-renewable resources; but durable | Renewable but resource-intensive production |

| Typical Applications | Lining, fast-fashion apparel, home decor, luggage | High-end fashion, luxury lingerie, fine furnishings |

As shown, imitated silk offers superior practicality for everyday use and high-turnover products, while natural silk remains the choice for ultimate luxury and natural breathability.

Top Applications of Imitated Silk Fabric in Industry

The versatility of imitated silk fabric makes it a sought-after material across multiple sectors. Its ability to provide a premium look with functional resilience is highly valued.

Fashion and Apparel

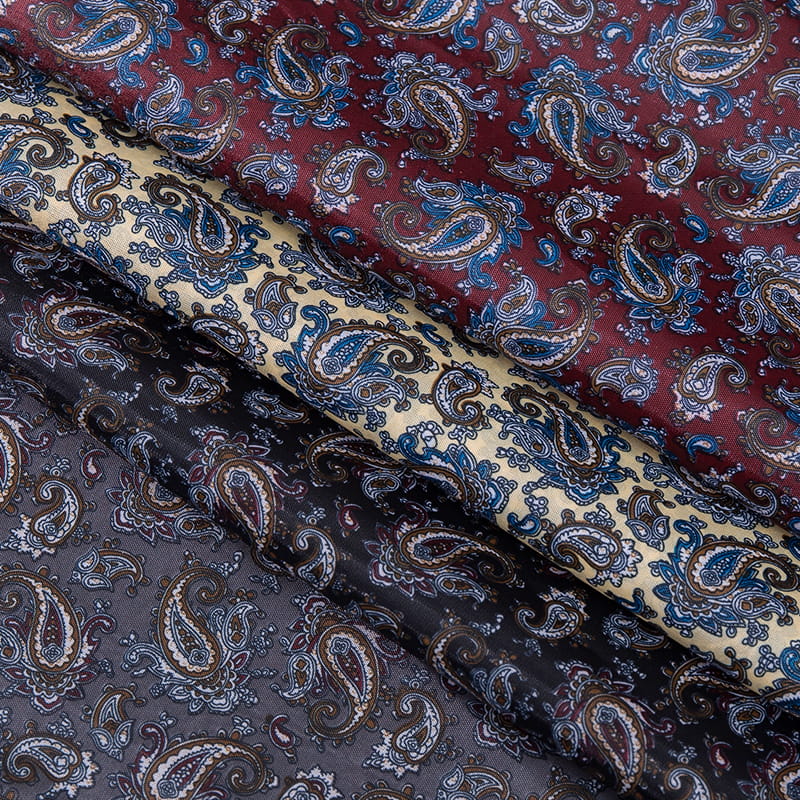

In the apparel industry, imitated silk fabric for luxury clothing at a lower cost has revolutionized accessible fashion. Designers utilize it to create blouses, dresses, scarves, and kimonos that offer a luxurious drape and sheen without the prohibitive cost and care instructions of natural silk. This is particularly prevalent in the women's silk lines segment, where style trends change rapidly. Furthermore, its smooth texture makes it an excellent choice for breathable and affordable silk-like linings in jackets, coats, and formal wear, enhancing comfort and garment structure.

Home Furnishings and Decor

The home decor market leverages the aesthetic appeal of imitated silk for curtains, drapery, cushion covers, and bedding. Durable faux silk for home decor curtains is a popular specification, as it resists fading from sunlight better than many natural fibers and is easier to clean, making it ideal for living spaces that require both elegance and practicality.

Luggage and Outdoor Goods

This is where the functional durability of synthetics shines. Imitated silk, particularly in jacquard weaves, is used for the interior lining of luggage, backpacks, and handbags. Its strength ensures the lining can withstand abrasion from contents, while its sheen adds a touch of interior luxury. For outdoor goods, specialized finishes can enhance its performance, aligning with the needs for materials that are both visually appealing and tough.

Selecting the Right Imitated Silk: A Buyer's Guide

Choosing the correct type of imitated silk fabric requires attention to several specifications to ensure it meets your product's demands.

Key Specifications to Evaluate

- Fiber Content and Denier: Typically 100% polyester or a blend. A lower denier indicates a finer, lighter, and more drapable fabric, suitable for flowing garments.

- Weave Type: Satin weaves are most common for a classic silk-like finish, while chiffon weaves offer a sheer, lightweight option. The choice between polyester satin vs chiffon for silk imitation depends on the desired opacity and drape.

- Weight (GSM): Ranges from lightweight (~30-70 GSM) for scarves to medium weight (70-120 GSM) for apparel and linings.

- Finish: Look for terms like "peach skin" (soft, matte), "high-shine," or "softened" to match the desired hand feel and visual effect.

Importance of Finishing Processes

The finishing process is what transforms a basic polyester fabric into a convincing silk alternative. Processes like calendaring polish the surface for shine, sanding creates a soft peach-skin effect, and chemical softening agents improve drape. These finishing touches are crucial for achieving best finishes for synthetic silk-like fabric feel and are a hallmark of quality manufacturing.

Manufacturing Expertise and Customization

Producing high-quality imitated silk is not merely about the raw materials; it hinges on technical expertise and production capacity. With 300 self-owned water jet looms and 100 matching twisters, our operation is built for scale and precision. Water jet looms are ideal for creating the tight, consistent weave necessary for a flawless silk-like surface without the residue that other methods may leave.

Our deep involvement in the production and finishing processes allows us to control every variable, from the twist of the yarn to the final heat setting. This vertical control is how we deliver cost-effective products under quality assurance conditions. Furthermore, our extensive equipment base enables rapid delivery of goods, a critical factor in today's fast-paced supply chains. We welcome and specialize in executing custom samples from foreign customers, tailoring weight, weave, finish, and color to meet specific brand needs for their outdoor functional clothing lines, luggage fabrics, or fashion collections.

Frequently Asked Questions (FAQs)

1. Is imitated silk fabric breathable like natural silk?

While high-quality imitated silk can be made with micro-porous fibers or specific weaves to improve air circulation, it generally does not match the exceptional moisture-wicking and breathability of natural silk. It is better suited for applications where durability and easy care are prioritized over ultimate breathability.

2. How should I care for products made from imitated silk?

Always check the care label. Most imitated silk is machine washable in cold water on a gentle cycle. Use a mild detergent and avoid bleach. It's best to air dry or tumble dry on low heat. Ironing should be done on a low-temperature setting.

3. Can imitated silk be used for outdoor applications?

Yes, but it depends on the specific finish. Standard imitated silk is not inherently weather-resistant. However, as producers of fabrics for outdoor goods, we can apply water-resistant or UV-resistant finishes during manufacturing to make the fabric suitable for specific outdoor decorative or accessory uses.

4. What is the minimum order quantity (MOQ) for custom imitated silk?

MOQs vary significantly by manufacturer. With our large-scale production capabilities, we can offer competitive MOQs and are flexible to discuss project-based quantities, especially when developing custom samples for overseas clients.

5. How does the cost of custom-dyed imitated silk compare to standard options?

Custom dyeing involves additional steps and minimum batch requirements, so it incurs a higher cost per meter than selecting from standard color lines. However, it ensures exact color matching for your brand, which is invaluable for product consistency and identity. The cost premium is often justified for brand-specific collections.

English

English русский

русский عربى

عربى