How to Care for and Maintain Satin Poly Pongee to Extend Its Lifespan: A Technical Guide

2026-01-14

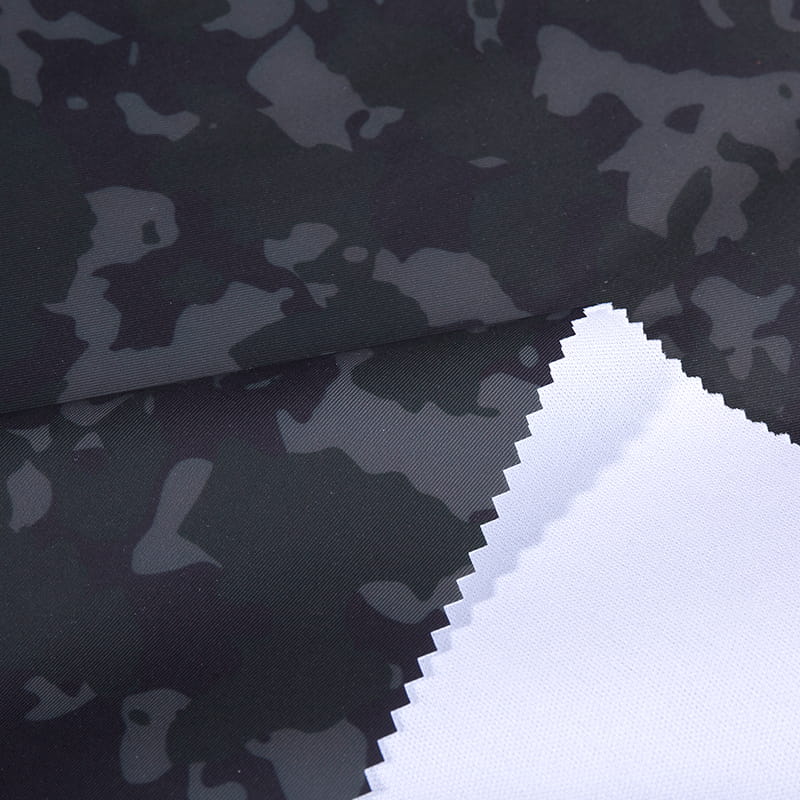

In the world of performance textiles, Satin Poly Pongee stands out for its unique combination of a soft, lustrous hand feel, inherent durability, and excellent water-repellency. For brands and manufacturers sourcing high-quality fabrics, understanding proper maintenance is not just about garment care—it's about protecting your investment in material integrity and ensuring end-user satisfaction. Proper care protocols directly influence color fastness, mechanical strength retention, and the preservation of functional finishes. Drawing from over two decades of specialized textile production, we understand that the longevity of a fabric like Satin Poly Pongee begins with precise engineering and is sustained through informed care.

Understanding Satin Poly Pongee: Fiber Science and Finish Integrity

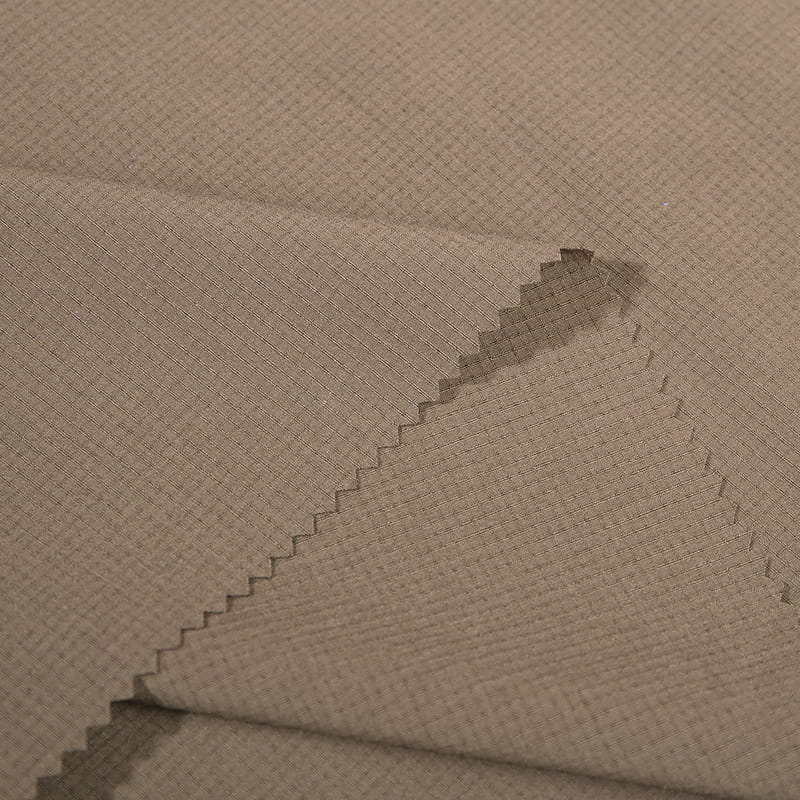

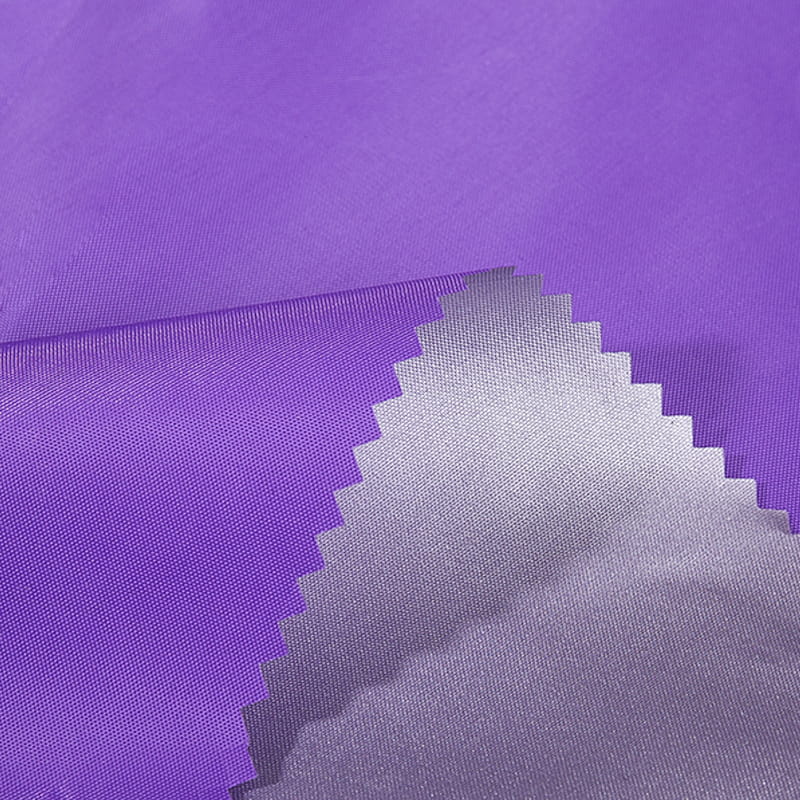

Satin Poly Pongee is a woven fabric primarily composed of filament polyester yarns. Its "satin" designation refers to the weave structure—typically a 4/1 or 5/1 warp-faced satin weave—which exposes more continuous filament yarns on the fabric surface. This construction is responsible for its characteristic smoothness and subtle sheen. The "pongee" aspect denotes a plain-weave base concept adapted here, often resulting in a lightweight yet tightly woven fabric. The performance hinges on two pillars: the innate properties of polyester and the applied chemical finishes.

- Polyester Core: Provides high tensile and tear strength, excellent dimensional stability, and quick-drying properties. It is inherently resistant to mildew and abrasion.

- Applied Finishes: Most Satin Poly Pongee receives a durable water repellent (DWR) treatment, often based on fluorocarbon polymers or newer PFAS-free alternatives. This finish is crucial for its functionality in outdoor and performance lines.

A critical point for B2B partners is that improper care can degrade these finishes long before the polyester fibers themselves wear out, directly impacting the product's market value.

5 Essential Care Protocols for Maximum Fabric Longevity

1. Washing: The Foundation of Textile Preservation

The single most impactful maintenance step is correct washing. Harsh laundering can strip DWR coatings and cause unnecessary mechanical stress.

- Use Cold or Lukewarm Water: High heat can permanently set oil-based stains and damage the molecular structure of water-repellent finishes. For example, washing at 30°C (86°F) is gentler on finishes than at 60°C (140°F).

- Mild, Liquid Detergent: Powdered detergents can leave residues that clog the fabric's micro-pores, reducing breathability. Avoid fabric softeners and bleach entirely, as they coat or break down fibers and finishes.

- Gentle Cycle and Load: A front-loading washer is preferable. Avoid overloading the machine to minimize friction and tangling.

2. Drying: Reactivating and Preserving Performance Finishes

Proper drying is not merely about removing moisture; it can reactivate and redistribute DWR treatments.

- Tumble Dry Low: Use a low heat setting (approximately 50-60°C / 122-140°F) for 20-30 minutes. The gentle tumbling and moderate heat help rejuvenate the DWR finish by allowing the polymers to reorient on the fiber surface.

- Air-Drying Alternative: If air-drying, ensure the fabric is fully smoothed out to prevent water spots. Line dry in the shade, as prolonged direct UV exposure can slowly degrade both fibers and finishes over time.

Source: Bluesign® - Guide to Sustainable Textile Finishing

3. Ironing and Heat Exposure: Managing Thermal Limits

Polyester has a specific glass transition and melting temperature range that dictates safe ironing practices.

- Low Heat Setting is Mandatory: Always use the "synthetic" or lowest heat setting on your iron (typically below 110°C / 230°F).

- Use a Press Cloth: Place a thin cotton cloth between the iron and the Satin Poly Pongee fabric. This prevents direct heat contact and potential glossing—a phenomenon where the satin weave fibers melt slightly, creating an unwanted shiny patch.

4. Stain Removal: Targeted Chemical Intervention

Address stains promptly using methods compatible with the fabric's chemistry.

- Blot, Don't Rub: Rubbing grinds the stain into the satin weave structure.

- Pre-treatment: Apply a small amount of mild liquid detergent directly to the stain and let it sit for 15 minutes before washing.

- Solvent Spot Testing: For stubborn oil-based stains, a specialized, non-chlorinated stain remover can be used after testing on an inconspicuous seam allowance. This is crucial for maintaining satin poly pongee fabric quality after wash.

5. Storage: Preventing Long-Term Degradation

Proper storage prevents unseen damage that compromises fabric performance. For long-term storage, such as with bulk satin poly pongee fabric rolls, ensure the environment is cool, dry, and dark. Store rolls vertically on end caps, never stacked flat for extended periods, to avoid pressure marks and fiber stress. For finished goods, avoid plastic bags; use breathable cotton garment bags instead.

Technical Comparison: Care Impact on Performance Metrics

The following data illustrates how proper versus improper care directly affects key performance indicators (KPIs) of Satin Poly Pongee. These metrics are vital for product developers and quality assurance teams.

| Performance Metric | Correct Care Protocol | Incorrect Care Protocol | Technical Impact & Rationale |

| Water Repellency (AATCC 22 Rating) | Maintains 80+ score after 20 washes | Drops below 50 after 5 washes | High heat and harsh detergents hydrolyze and wash off DWR polymer chains. |

| Tensile Strength Retention | >95% after 50 wash cycles | ~80% after 50 wash cycles | Mechanical abrasion in overloaded washers causes micro-fibrillation of polyester filaments. |

| Color Fastness to Washing | Grade 4-5 (Excellent) | Grade 3 (Moderate fading) | Bleach or high-pH detergents attack dye molecules and fabric surface. |

| Fabric Hand Feel | Retains original soft, smooth drape | Becomes stiff or develops "glazing" | Fabric softeners coat fibers; high-heat ironing melts fiber surfaces. |

Industry Context: The Drive for Durability and Sustainable Care

The focus on extending textile lifespan is now central to both industry standards and environmental initiatives. According to the latest report by the International Organization for Standardization (ISO), there is a heightened push towards standardizing "durability of performance" tests, moving beyond just initial property checks. This shift directly impacts fabrics like Satin Poly Pongee, where DWR longevity is a key benchmark. Simultaneously, 2024 research highlights a trend towards next-generation DWR technologies that offer comparable performance with significantly improved environmental and health profiles, aligning with regulations like EU's REACH. These finishes are designed to be more resistant to repeated washes, addressing a major pain point for waterproof satin poly pongee for rainwear. For manufacturers, this means that specifying the right base fabric and finish during production is the first step in ensuring easier care and longer life for the end consumer, reducing the total cost of ownership and environmental footprint.

Source: ISO - New Draft Standards on Textile Durability

Source: OEKO-TEX® - 2024 Annual Report on Finishing Technologies

Expert Insights from the Production Floor

Our experience operating 300 water jet looms has shown that the fabric's inherent quality sets the ceiling for its potential lifespan. For instance, the even application of DWR during finishing is critical; an uneven coat will lead to patchy water repellency after the first wash. This is why we advise clients sourcing lightweight satin poly pongee for linings to inquire about the finishing process. Furthermore, the practice of accepting custom satin poly pongee samples allows brands to pre-test care protocols on their exact fabric specification before committing to bulk production. This step can prevent costly post-production issues related to care labeling and customer returns.

Frequently Asked Questions (FAQ)

Can I dry-clean Satin Poly Pongee garments?

It is generally not recommended. The chemical solvents used in traditional dry-cleaning, especially perchloroethylene (perc), can be overly aggressive and may strip the DWR finish more effectively than water-based washing. For optimal longevity, follow the gentle cold wash and tumble dry low method outlined above.

How often should I reapply a DWR treatment?

This depends on use and wash frequency. A key sign is when water no longer beads up on the surface but instead soaks into the fabric. With proper care (cold wash, dry low), a high-quality DWR on Satin Poly Pongee can last the lifetime of a garment intended for moderate use. For heavy-use items like technical rainwear, a reapplication after 20-30 washes may be necessary using a heat-activated spray-on or wash-in repellent.

Why does my fabric feel stiffer after washing?

This is often caused by using powdered detergent or fabric softener, or by air-drying without proper tumbling. Powder detergent residues mineralize within the weave. Fabric softeners coat the fibers, masking their natural drape. To restore softness, re-wash with a small amount of mild liquid detergent and tumble dry on low heat.

Is Satin Poly Pongee prone to pilling?

High-quality Satin Poly Pongee made from continuous filament yarns has very low pilling propensity. Pilling is more common in fabrics made from spun (short staple) yarns. The smooth filament surface of satin-weave polyester resists the entanglement that causes pills. If pilling occurs, it is likely due to excessive abrasion against rough surfaces or a lower-quality fabric blend.

How does care differ for lining vs. outer shell fabric?

The core principles are the same. However, lightweight satin poly pongee for linings may be more delicate in terms of weave. Extra care should be taken to avoid snagging (e.g., from zippers or Velcro) during washing. Turning a garment inside out before washing provides an extra layer of protection for lining fabrics.

English

English русский

русский عربى

عربى