How Does Combined Polyester Fabric Compare to Pure Polyester or Blended Fabrics?

2026-01-21

Understanding Fabric Terminology: Combined, Pure, and Blended

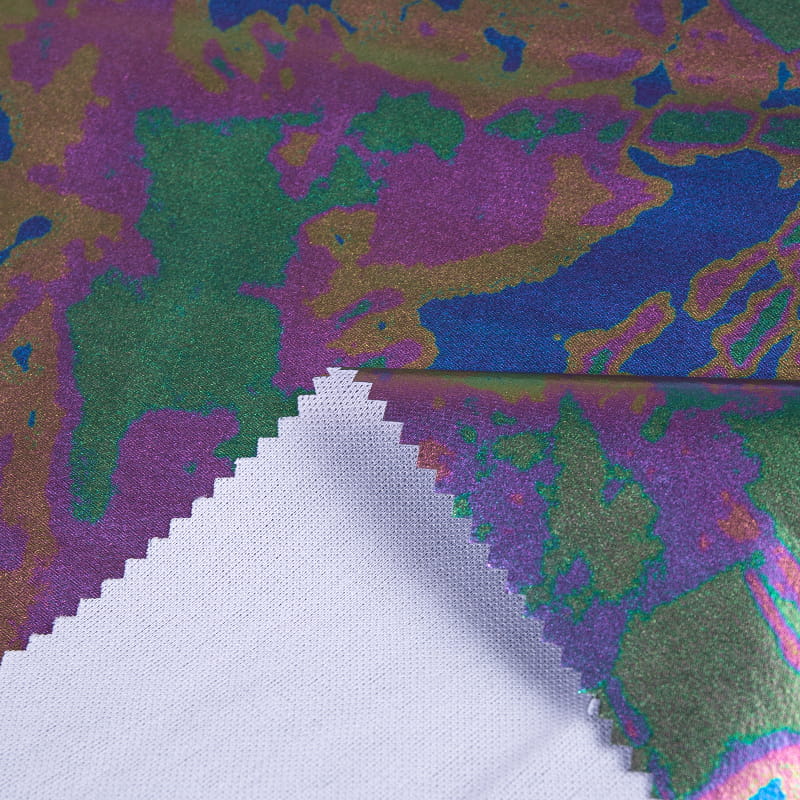

The world of synthetic textiles can be complex, with terminology often used interchangeably despite referring to distinct manufacturing processes and material structures. For professionals and enthusiasts seeking the right material for specific applications, understanding these differences is paramount. At the center of this discussion is combined polyester fabric, a term that denotes a specific construction method often misunderstood. This fabric is engineered by bonding or laminating two or more layers of material, at least one of which is predominantly polyester. This process is fundamentally different from creating a blended yarn, where different fibers are mixed at the fiber or yarn stage before weaving or knitting. The "combination" refers to the layered structure, which can unite a polyester layer with another fabric like cotton, nylon, or even a membrane, or it can involve multiple layers of polyester with different treatments or weaves. This engineering allows for targeted performance enhancements that are difficult to achieve through blending alone. In contrast, pure polyester fabric is woven or knitted from 100% polyester filaments or staples, offering uniformity in performance derived from a single polymer source. Blended fabrics, such as the classic poly-cotton, involve the intimate mixing of polyester fibers with natural or other synthetic fibers into a single yarn, aiming to balance the properties of each component. The confusion often arises because a combined fabric might *contain* a blend within one of its layers, but the core principle remains the layering. The growing interest in durability of combined polyester vs traditional materials stems from this layered architecture's potential to offer superior longevity and specific functional advantages. This section will delve deeper into the technical definitions and manufacturing nuances that set these three categories apart, providing a foundational understanding crucial for making informed material selections.

Key Performance Factors in Textile Selection

Selecting a fabric is never a decision based on a single attribute; it requires a holistic evaluation of multiple, often competing, performance factors. The end-use of the textile dictates the priority of these factors. For instance, athletic wear demands high moisture-wicking and breathability, while outdoor upholstery prioritizes UV resistance and tensile strength. In this comparative landscape, the intrinsic and engineered properties of combined polyester, pure polyester, and blended fabrics come to the fore.

Durability and Longevity

Durability encompasses a fabric's resistance to abrasion, pilling, tearing, and its ability to maintain integrity through repeated wear and washing cycles. Pure polyester is inherently strong due to the toughness of the polyester polymer, with excellent resistance to stretching, shrinking, and most chemicals. However, its surface can be prone to pilling in staple form, and it can be vulnerable to snags. Blended fabrics, like polyester-cotton, often see a compromise; the polyester adds strength to the more vulnerable cotton, but the cotton component can weaken over time, especially when wet, and is more susceptible to abrasion and microbial damage. The durability of combined polyester vs traditional materials presents a compelling case. By strategically layering materials, a combined fabric can place a highly abrasion-resistant polyester layer on the exterior, a waterproof membrane in the middle, and a soft, quick-drying layer on the interior. This targeted engineering often results in a product that outperforms both pure and blended fabrics in specific durability tests. For example, a combined fabric with a high-denier polyester face will resist scuffing far better than a standard blended knit. The bond between layers is critical; a well-constructed combination will not delaminate, ensuring the longevity of the enhanced properties.

Comfort and Wearability

Comfort is a subjective yet critical factor, influenced by breathability, moisture management, softness, weight, and drape. Pure polyester has historically been criticized for feeling "clammy" or having a plastic-like hand feel, as it is hydrophobic and can trap moisture vapor. Modern micro-denier and textured polyester filaments have significantly improved this, but the perception persists. Blended fabrics, particularly with cotton, rayon, or wool, immediately improve moisture absorption and softness, giving a more natural and breathable feel against the skin. This is why they dominate everyday casual wear. The narrative shifts when we examine combined polyester fabric breathability and moisture wicking in high-performance contexts. A combined fabric can be engineered to excel in active scenarios. For instance, a common combination features a mesh-like polyester interior layer for rapid moisture movement (wicking) away from the skin, a middle layer that disperses the moisture, and an outer layer that facilitates rapid evaporation. This systematic management of perspiration often surpasses the capability of a homogeneous blend, which relies on the capillary action of mixed fibers alone. The comfort here is dynamic—focused on maintaining a dry microclimate during physical activity rather than simply offering initial softness.

Thermal Regulation and Insulation

Closely tied to comfort is a fabric's ability to provide warmth or cooling. This is a key area where thermal properties of combined polyester layers are expertly manipulated. Pure polyester provides some insulation by trapping air within its fibers but offers little adaptive regulation. Blended fabrics take on the thermal character of their dominant fiber. Combined fabrics, however, can create sophisticated thermal barriers. For cold environments, a combination might use a dense, brushed polyester inner layer to trap warm air, a windproof middle membrane, and a durable outer shell. For heat, a combination could use a loose, breathable outer weave, a moisture-wicking inner layer, and a design that promotes air circulation between the layers. This level of programmable thermal performance is the hallmark of advanced combined textiles, making them the choice for technical outerwear, sportswear, and protective gear where environmental conditions are a primary concern.

Care, Maintenance, and Environmental Impact

The practicalities of caring for a fabric and its ecological footprint are increasingly important. Pure polyester is notoriously easy to care for: it is machine washable, dries quickly, resists wrinkles, and requires little ironing. Blended fabrics inherit care instructions from their most delicate component; a polyester-wool blend, for example, will require more gentle washing than pure polyester. Care instructions for combined polyester fabric blends can vary widely and are entirely dependent on the materials used in each layer. A combination of polyester and nylon might be as easy-care as pure polyester, but one incorporating leather or a delicate bonded film might require specialist cleaning. Always following the manufacturer's label is essential for combined fabrics to prevent delamination or damage to sensitive layers. From an environmental perspective, pure polyester is derived from petrochemicals and is non-biodegradable, though recyclable. Blends present a recycling challenge due to the difficulty of separating fibers. The environmental impact of producing combined polyester textiles is complex. The multi-layer construction often uses adhesives or bonding agents, which can complicate recycling. However, their durability can lead to a longer product life, offsetting initial impacts. Furthermore, innovations are emerging, such as combining recycled polyester layers with bio-based membranes, aiming to reduce the overall ecological footprint of these performance-driven textiles.

Direct Comparison: Combined vs. Pure vs. Blended

To crystallize the distinctions, a side-by-side comparison across several key parameters is invaluable. The following table summarizes the general characteristics, though specific fabric constructions can yield exceptions.

| Attribute | Pure Polyester Fabric | Blended Fabrics (e.g., Poly-Cotton) | Combined Polyester Fabric |

|---|---|---|---|

| Construction | 100% polyester yarns, woven or knitted. | Yarns made from a mix of fibers (e.g., 65% polyester, 35% cotton). | Two or more layers (at least one polyester) bonded/laminated together. |

| Primary Strength | High tensile strength, excellent shape retention, wrinkle resistance. | Balanced properties; polyester adds strength, natural fiber adds comfort. | Engineered for specific, high-performance durability; often superior abrasion resistance. |

| Moisture Management | Hydrophobic; wicks moisture but can feel clammy if not engineered. | Improved absorption and breathability from natural fiber component. | Can be highly advanced, with dedicated layers for wicking, dispersal, and evaporation. |

| Comfort & Feel | Can be smooth or stiff; modern versions are softer. | Generally softer, more breathable, and more natural feel from Day 1. | Varies; can be stiff if designed for shells, or plush if lined. Functional over tactile. |

| Thermal Regulation | Moderate insulation, low adaptability. | Depends on blend; often good for moderate climates. | Highly adaptable; can be engineered for extreme cold, heat, or wind/water protection. |

| Care & Maintenance | Very easy; machine wash, quick dry, low iron. | Generally easy, but follows care needs of the most delicate fiber. | Can be complex; strictly follow label to preserve layer integrity. |

| Common Applications | Sportswear, outdoor furniture, flags, packaging. | Everyday apparel (t-shirts, shirts), bed linens, casual wear. | Technical outerwear (rain jackets, ski suits), performance sportswear, specialized uniforms, high-stress upholstery. |

Strategic Applications: Choosing the Right Fabric

The choice between these fabric types is not about which is universally "better," but which is optimal for a specific purpose. Understanding their inherent strengths guides this strategic selection.

When to Choose Combined Polyester Fabric

Opt for combined polyester when the application demands high, specialized performance that a single material or simple blend cannot provide. This is particularly relevant in scenarios demanding multi-functional protection or where durability of combined polyester vs traditional materials is the deciding factor.

- Technical Outerwear and Active Gear: This is the prime domain. Jackets requiring waterproofness, windproofness, and breathability (e.g., using a polyester face, PTFE membrane, and polyester tricot backer) are classic examples. The layers work in concert to protect from elements while managing physiological comfort.

- High-Abrasion Environments: Workwear, tactical gear, backpacking equipment, and automotive upholstery that faces constant friction benefit immensely. A combined fabric can place an ultra-tough polyester canvas exterior over a more flexible or insulating underlayer, extending product life significantly.

- Specialized Performance Apparel: For sports where managing extreme body conditions is key, the advanced combined polyester fabric breathability and moisture wicking systems are unmatched. Running suits, cycling jerseys, and mountaineering layers use combination technology to regulate temperature and sweat with precision.

- Applications Requiring Specific Barrier Properties: This includes medical textiles (fluid barriers), industrial workwear (chemical splashes), or insulated packaging. The ability to combine a robust polyester layer with a specialized film or coating makes combined fabrics ideal.

When to Choose Pure Polyester or Blended Fabrics

Pure polyester and blends remain superior for vast segments of the market where cost-effectiveness, simplicity, and everyday comfort are key.

- High-Volume Casual Apparel and Home Textiles: For everyday t-shirts, simple trousers, bedsheets, and curtains, blended fabrics like poly-cotton offer an excellent balance of comfort, durability, ease of care, and cost. The breathability and softness of cotton combined with the strength and shrink-resistance of polyester is a proven, economical formula.

- Applications Requiring Uniformity and Consistency: Pure polyester is ideal for products like flags, banners, or certain types of luggage where consistent color fastness, weather resistance, and dimensional stability are required without the need for complex layered comfort.

- Budget-Conscious Projects with Standard Requirements: When specialized performance features like extreme weather protection or advanced moisture systems are unnecessary, pure polyester or standard blends provide more than adequate performance at a lower price point and with simpler care instructions for combined polyester fabric blends.

- Where Simplicity in Sourcing and Manufacturing is Key: Pure and blended fabrics are widely available, easier to sew and construct with, and have predictable behaviors, making them the default for a huge range of standard products.

A final, crucial consideration across all choices is sustainability. The industry is evolving, and assessing the environmental impact of producing combined polyester textiles versus the potentially longer life they offer is a necessary part of the decision-making process for many developers and consumers today.

The Future of Fabric Engineering

The trajectory of textile innovation points towards greater intelligence and specialization. Combined fabrics represent a significant step in this journey, moving beyond the limitations of single-material or homogeneously mixed fibers. The future will likely see combined polyester fabrics integrating smart technologies—such as phase-change materials for dynamic thermal properties of combined polyester layers, or conductive yarns for data monitoring—directly into their laminated structures. Sustainability will drive the development of mono-material combinations (all layers based on recyclable polyester) and the use of bio-based adhesives and membranes to address the environmental impact of producing combined polyester textiles. Furthermore, seamless integration of wearable tech within these layered architectures will blur the line between garment and device. For the optimizer or product developer, this means that the choice of fabric is becoming increasingly strategic. Understanding the fundamental paradigm shift that combined fabrics represent—from homogeneous properties to programmable, zone-specific performance—is essential for selecting materials that truly meet the demanding and nuanced requirements of modern applications, from elite sport to everyday life enhanced by technology.

English

English русский

русский عربى

عربى