A Comprehensive Guide to Combined Polyester Fabric: Performance, Uses, and Manufacturing

2026-01-28

In the dynamic world of textiles, innovation is constant. Among the many advanced materials available, combined polyester fabric stands out for its versatility and enhanced performance. This fabric is engineered by weaving or knitting polyester filaments or yarns with other fibers, creating a hybrid material that leverages the strengths of each component. For businesses sourcing high-quality textiles, understanding this material is crucial. As a family-owned plant with over two decades of expertise in producing polyester nylon fabrics and various linings, we have deep insight into the production and applications of these sophisticated materials. This guide delves into the specifics of combined polyester fabrics, offering valuable information for manufacturers and designers.

What is Combined Polyster Fabric? A Technical Overview

At its core, combined polyester fabric is not a single entity but a category. It refers to textiles where polyester is intentionally blended or combined with one or more other fibers during the spinning, weaving, or knitting process. The goal is to create a fabric with properties superior to those of 100% polyester or the other fiber alone.

Common Fiber Combinations with Polyester

Polyester-Cotton Blends

- Comfort & Durability: Cotton provides breathability and softness, while polyester adds strength, wrinkle resistance, and shape retention.

- Typical Ratios: Common blends include 65% polyester/35% cotton and 50/50 mixes, balancing cost and performance.

Polyester-Nylon Blends

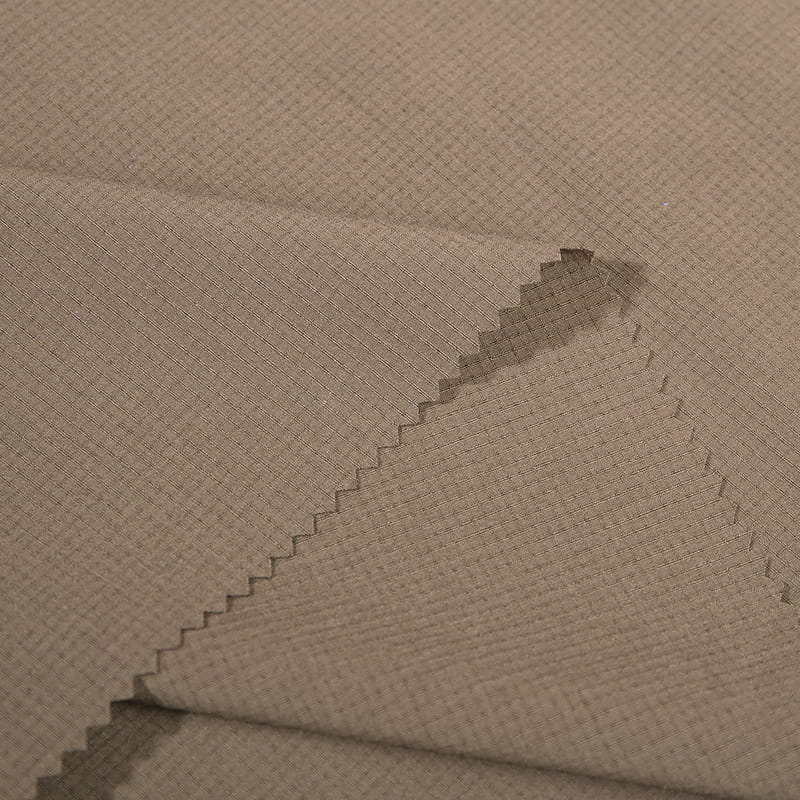

- Strength & Abrasion Resistance: This combination is a powerhouse for durability. Nylon's exceptional tensile strength and elasticity complement polyester's resilience and quick-drying properties.

- Primary Use: Highly favored in outdoor functional clothing lines and gear like backpacks and tents.

Polyester-Spandex (Elastane) Blends

- Flexibility & Fit: The addition of a small percentage of spandex (typically 5-15%) grants significant stretch and recovery, essential for activewear and form-fitting garments.

Polyester-Wool Blends

- Warmth & Refinement: Wool enhances thermal insulation and aesthetic drape, while polyester reduces shrinkage, increases durability, and lowers cost.

Key Advantages and Applications of Combined Polyester Fabrics

The strategic blending of fibers unlocks a wide array of benefits, making these fabrics suitable for diverse industries.

Enhanced Performance Characteristics

- Improved Durability and Longevity: Polyester's inherent strength often boosts the wear resistance of the blend, leading to longer-lasting products.

- Superior Moisture Management and Quick-Drying: While polyester itself is hydrophobic, blending it with hydrophilic fibers like cotton can create effective moisture-wicking systems. Pure polyester-nylon blends dry extremely quickly.

- Wrinkle and Shrink Resistance: Polyester stabilizes blends, minimizing wrinkles and shrinkage compared to natural fibers alone, reducing maintenance effort.

- Cost-Effectiveness: Incorporating polyester often lowers the final fabric cost compared to using high-end natural fibers exclusively, without a drastic sacrifice in quality.

Industry-Specific Applications

Outdoor and Functional Apparel

This is a primary domain for high-performance blends. For instance, the difference between a pure nylon fabric and a polyester nylon blend for outdoor gear can be significant. The blend often offers a better balance of tear strength, abrasion resistance, and UV stability, while also being more cost-effective for high-volume production runs common in this sector.

| Feature | Pure Nylon Fabric | Polyester-Nylon Blend Fabric |

| Abrasion Resistance | Excellent | Excellent to Superior (synergistic effect) |

| UV Degradation | Higher susceptibility | Improved resistance (polyester offers better UV stability) |

| Moisture Absorption | Moderate (can feel clammy) | Lower (dries faster, better for wet conditions) |

| Cost Efficiency | Generally Higher | More Cost-Effective for bulk production |

Fashion and Apparel

From durable everyday wear like polo shirts (polyester-cotton) to elegant women's silk blend fabrics with polyester, these materials are ubiquitous. The polyester adds practicality and structure to delicate silk, making garments more wearable and easier to care for.

Luggage and Heavy-Duty Goods

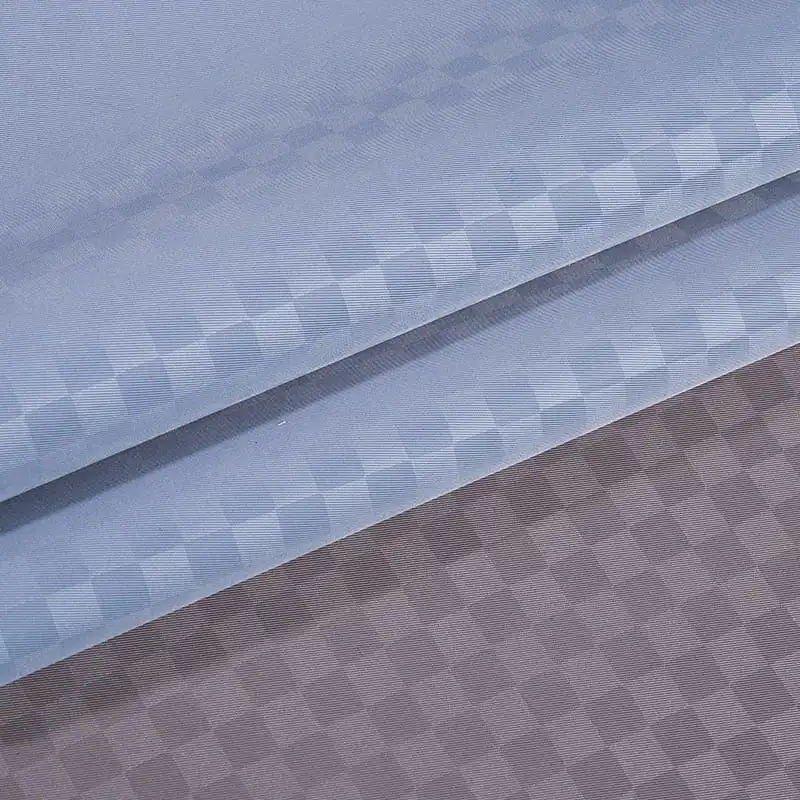

For durable jacquard luggage fabric blends, the combination of polyester and nylon is paramount. The jacquard weave provides a distinctive, often branded pattern, while the fiber blend ensures the material can withstand the rigors of travel. The fabric must be resistant to tearing, scuffing, and moisture.

Home Textiles and Technical Uses

Bed linens, curtains, and upholstery benefit from polyester-cotton or polyester-wool blends, which offer ease of care and durability. Technically, these fabrics are also used in automotive interiors and industrial applications.

In-Depth Look: Manufacturing and Finishing Processes

The quality of a combined polyester fabric is determined long before it reaches the cutting table. It hinges on precise manufacturing and expert finishing.

The Weaving and Knitting Stage

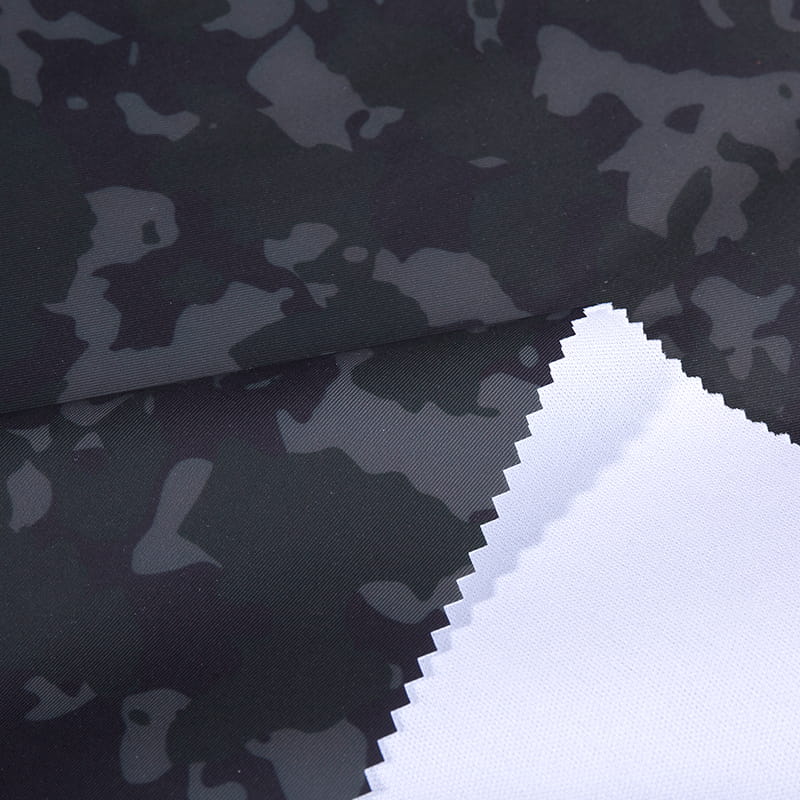

This is where the fiber combination becomes a cohesive textile. Advanced looms, like the water-jet looms we operate, interlace the warp and weft yarns. The choice of weave (plain, twill, satin, jacquard) dramatically affects the fabric's appearance, texture, strength, and drape. For example, a jacquard luggage fabric requires a specialized loom head to create its intricate, raised patterns.

Critical Finishing Treatments

Finishing transforms raw greige goods into a functional fabric. Key treatments for performance fabrics include:

- Dyeing and Printing: Ensuring color fastness and vibrancy.

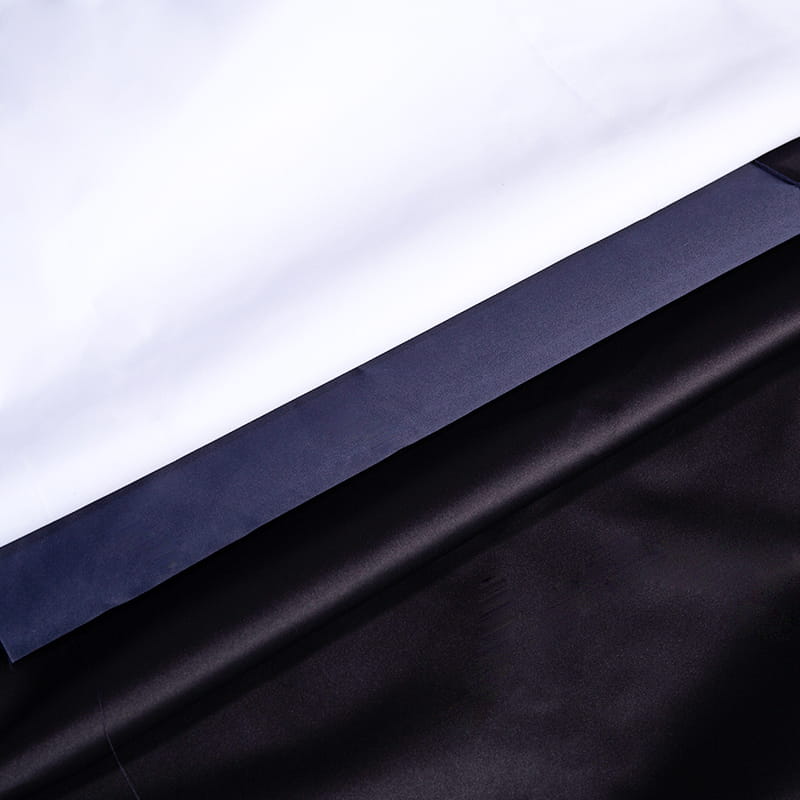

- Water-Repellent (DWR) Finishes: A crucial treatment for waterproof breathable polyester blend fabric used in outerwear. This finish causes water to bead up and roll off the surface.

- Calendering and Heat-Setting: These processes control the fabric's hand feel, sheen, and dimensional stability, ensuring it doesn't shrink or distort during garment production.

The difference between a fabric with and without a proper DWR finish is stark. A finished fabric will shed water, keeping the wearer dry, while an unfinished fabric of the same blend will allow water to soak in.

| Aspect | Fabric WITHOUT DWR Finish | Fabric WITH DWR Finish |

| Water Beading | Water spreads and soaks into the fabric | Water forms beads and rolls off the surface |

| Breathability in Wet Conditions | Severely reduced as fabric wets out | Maintained longer as the face fabric remains drier |

| Drying Time | Slower | Faster (surface water sheds easily) |

Quality Assurance in Production

For a manufacturer, rigorous QA is non-negotiable. This involves testing for:

- Fabric weight (GSM)

- Tensile and tear strength

- Colorfastness to washing and light

- Shrinkage rates

- Performance of specialty finishes (e.g., water column pressure for waterproof fabrics)

Operating for over 20 years has ingrained a culture of quality at every stage, from inspecting incoming yarns to final roll inspection, ensuring cost-effective products under quality assurance conditions.

Choosing the Right Fabric for Your Project

Selecting the optimal combined polyester fabric requires careful consideration of the end-use.

Performance vs. Aesthetics

- Outdoor Gear: Prioritize strength, abrasion resistance, waterproofness, and UV stability. Polyester-nylon blends with a DWR finish are often ideal.

- Fashion Apparel: Balance drape, hand feel, color richness, and care requirements. A women's silk blend fabric with polyester focuses on luster and elegant drape with added durability.

Importance of Fabric Weight and Denier

Weight (in grams per square meter, GSM) and denier (thickness of the yarn) directly correlate with durability and suitability. A heavy-duty backpack requires a high-denier, high-GSM fabric (e.g., 600D), while a lightweight running shirt requires a very low GSM fabric.

The Value of Sourcing from an Experienced Manufacturer

Partnering with a specialized producer offers distinct advantages:

- Expert Guidance: Navigating fiber blends, weaves, and finishes can be complex. An experienced team can recommend the most efficient solution for your needs.

- Customization Capability: The ability to accept custom samples from foreign customers is a key service. It allows for the development of proprietary fabrics tailored to specific design and performance requirements.

- Supply Chain Reliability: A vertically integrated operation with substantial in-house capacity, such as a facility with hundreds of looms and twisters, ensures consistent quality and rapid delivery of goods, mitigating supply chain risks.

Frequently Asked Questions (FAQ)

1. What is the main benefit of using a combined polyester fabric over 100% polyester?

The main benefit is the ability to engineer specific properties that pure polyester may lack. By blending with other fibers, you can significantly improve comfort (e.g., with cotton), stretch (with spandex), ultimate strength (with nylon), or aesthetic warmth and drape (with wool), creating a more balanced and application-specific material.

2. Is polyester-nylon blend fabric truly waterproof?

The fabric weave itself is not inherently waterproof. However, a tightly woven polyester nylon blend for outdoor gear can be made waterproof through the application of a coating (e.g., polyurethane) or a laminate (e.g., ePTFE membrane) on the back of the fabric. The face fabric is then treated with a DWR finish to make it water-repellent. This creates a complete waterproof breathable polyester blend fabric system.

3. How does adding silk to polyester affect the fabric's care?

Adding polyester to silk drastically simplifies care. While pure silk often requires dry cleaning or very delicate hand washing, a women's silk blend fabric with polyester becomes more resistant to wrinkles and shrinking, and is often machine-washable on a gentle cycle. Always check the specific care label, but the blend introduces much-needed practicality.

4. What makes a fabric suitable for durable luggage?

Durable jacquard luggage fabric blends require high abrasion resistance, high tear strength, and good resistance to dirt and moisture. A polyester-nylon blend in a jacquard weave is common because it provides the necessary structural durability while allowing for complex, branded patterns that are woven in, not just printed on, ensuring they don't fade or scratch off easily.

5. Can I develop a custom combined polyester fabric for my brand?

Yes, reputable manufacturers with extensive experience often offer this service. The process typically involves discussing your performance requirements, aesthetic goals, and budget. The manufacturer will then propose fiber blends, weaves, and finishes, and produce sample swatches for your evaluation before proceeding to bulk production. This collaborative development is key to creating unique, high-performance products.

Combined polyester fabric represents the intelligent evolution of textile engineering, offering tailored solutions across industries from high-performance outdoor gear to elegant fashion and durable luggage. Understanding the nuances of fiber combinations, manufacturing processes, and finishing treatments is essential for making informed sourcing decisions. For businesses looking for reliability, customization, and expertise, partnering with an established manufacturer is invaluable. With decades of hands-on experience in weaving, finishing, and quality control, we are committed to turning fabric specifications into reality, ensuring that the materials powering your products are built to last and perform.

References

[1] Hu, J. (2008). *Fabric Testing*. Woodhead Publishing in Textiles. This source provides comprehensive methodologies for testing fabric properties like tensile strength, tear resistance, and colorfastness, which are critical for quality assurance in combined fabrics.

[2] Sinclair, R. (2015). *Textiles and Fashion: Materials, Design and Technology*. Woodhead Publishing. This text offers foundational knowledge on fiber properties, blending principles, and the impact of different weaves and finishes, informing the sections on fabric composition and performance.

[3] Fung, W., & Hardcastle, M. (2001). *Textiles in Automotive Engineering*. Woodhead Publishing. While focused on automotive use, this book details the performance demands on technical textiles, supporting the discussion on durability and functional finishes for polyester blends.

English

English русский

русский عربى

عربى