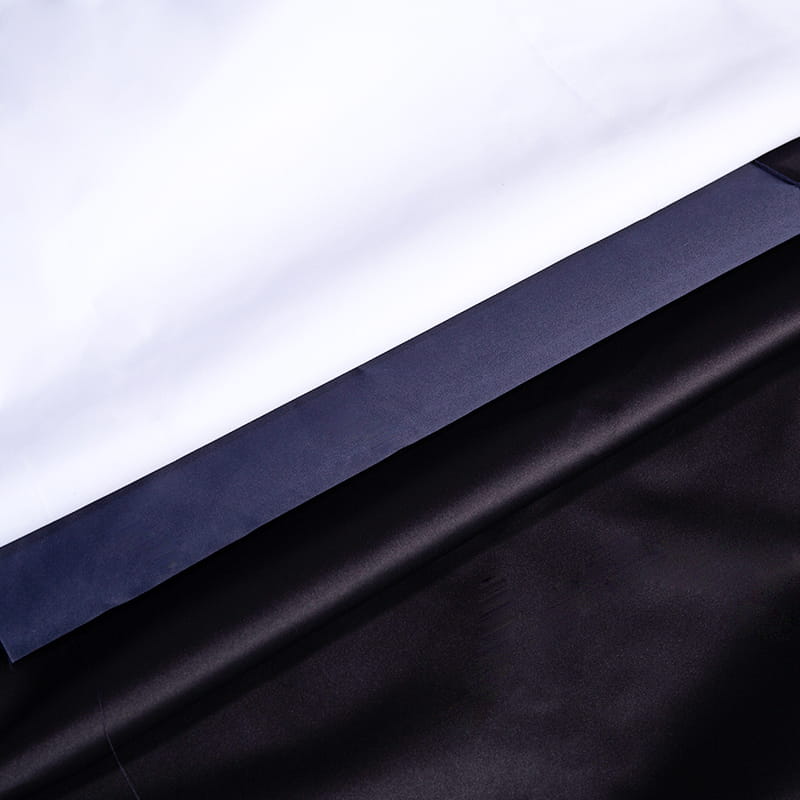

The Complete Guide to Imitated Silk Fabric: Elegance, Performance, and Value

2026-02-04

For decades, silk has been synonymous with luxury, sheen, and delicate comfort. However, its high cost, demanding care requirements, and specific performance limitations have driven innovation in the textile industry. Enter imitated silk fabric – a sophisticated category of textiles engineered to capture the aesthetic essence of silk while offering enhanced durability, practicality, and affordability. As a family-owned textile plant with over 20 years of expertise in weaving and finishing, we understand this evolution intimately. This guide delves deep into the world of imitated silk, exploring its types, benefits, applications, and how it compares to its natural counterpart, providing you with the knowledge to make informed material choices.

What is Imitated Silk Fabric?

Imitated silk fabric, often referred to as artificial or synthetic silk, is a man-made textile designed to visually and tactilely resemble genuine silk. It is not a single fiber but a broad term encompassing fabrics made from various synthetic or regenerated fibers through specific weaving and finishing techniques. The goal is to replicate the characteristic drape, luster, and smooth hand-feel of silk without relying on silkworms.

Primary Fiber Types Used

Polyester-Based Imitated Silk

- Dominant Material: The most common and cost-effective base for imitated silk.

- Key Traits: Exceptional strength, wrinkle resistance, and quick-drying properties.

- Finishing Process: Through processes like sanding, calendering, and chemical treatments, polyester filaments are given a soft, smooth finish and subtle sheen akin to silk.

Nylon-Based Imitated Silk

- Notable Characteristics: Offers a brilliant, sometimes brighter luster and a exceptionally silky hand.

- Performance Edge: Renowned for its high abrasion resistance and elasticity.

- Common Use: Frequently used in linings, lingerie, and accessories where durability and a luxe feel are paramount.

Rayon/Viscose-Based Imitated Silk

- Closest to Natural: As a regenerated cellulose fiber, it more closely mimics the moisture-absorption and drape of real silk.

- Aesthetic Quality: Provides a beautiful, fluid drape and a soft, comfortable feel against the skin.

- Consideration: Can be less wrinkle-resistant than polyester and requires more careful washing.

Key Advantages of Choosing Imitated Silk

The rise of imitated silk fabric is no accident. It solves several practical challenges posed by natural silk, making luxury aesthetics accessible for broader applications.

Superior Durability and Strength

Unlike delicate natural silk, which can be weakened by perspiration and sunlight, imitated silk fibers like polyester and nylon are inherently robust. Fabrics made from these fibers resist tearing, pilling, and abrasion far better, ensuring garments and products maintain their integrity over time and with frequent use.

Enhanced Practicality and Ease of Care

- Wrinkle Resistance: Many imitated silks, especially polyester blends, emerge from the wash with minimal creasing.

- Machine Washable: Most varieties are safe for gentle machine washing, a significant advantage over dry-clean-only natural silk.

- Quick Drying: Synthetic fibers do not retain water like natural ones, drastically reducing drying time.

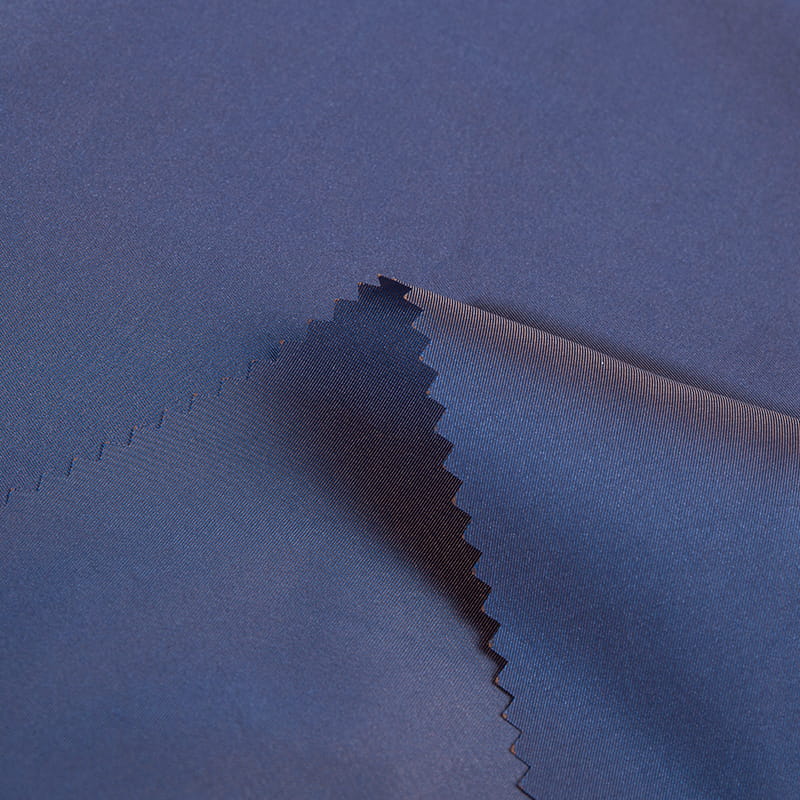

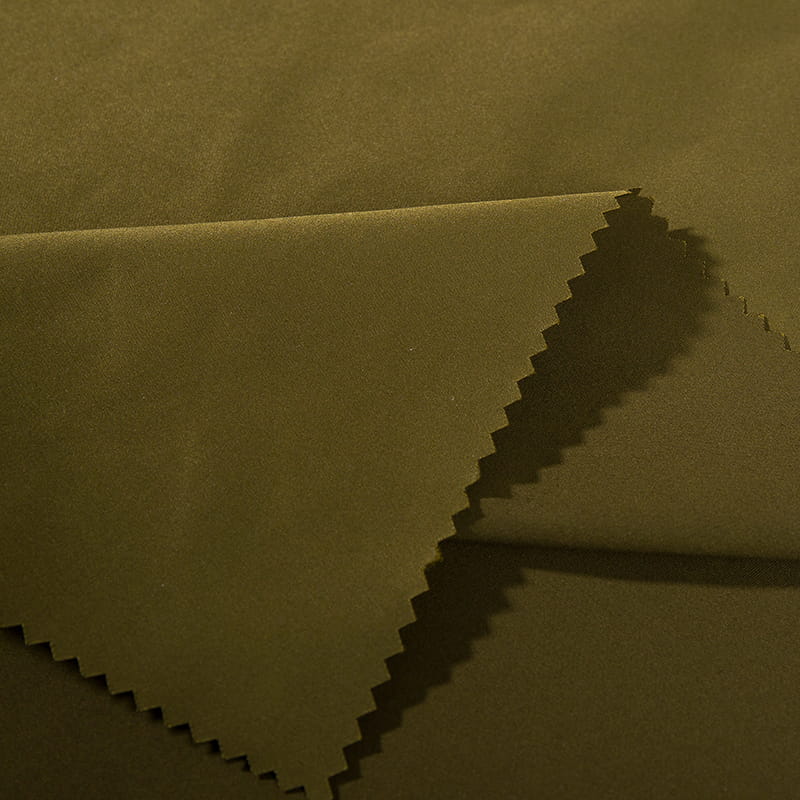

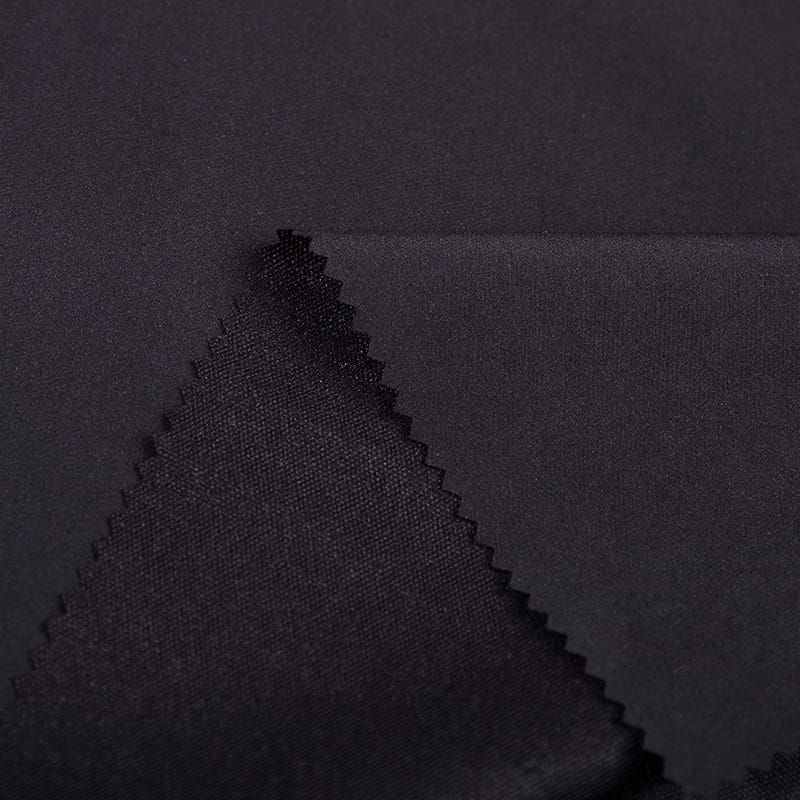

Excellent Color Fastness and Versatility

Synthetic fibers accept dyes beautifully, resulting in vibrant, rich colors that are often more resistant to fading from washing and UV exposure than natural silk. This, combined with advanced weaving techniques on equipment like water jet looms, allows for a vast array of patterns, textures, and weights, from sheer chiffons to substantial jacquards.

Outstanding Cost-Effectiveness

This is perhaps the most compelling advantage. The production of imitated silk fabric is less resource-intensive and more scalable than cultivating silkworms. This efficiency translates directly to a lower price point, allowing designers and brands to incorporate a silk-like aesthetic into products at a fraction of the cost. For businesses, this means better margin potential; for consumers, it means accessible luxury.

Imitated Silk vs. Natural Silk: A Detailed Comparison

Choosing between imitated and natural silk depends largely on the project's priorities. The following comparison highlights their key differences.

While natural silk is unparalleled in its natural protein structure and certain traditional aspects, imitated silk fabric offers a compelling balance of beauty and performance for modern applications. For instance, natural silk provides superior moisture absorption for skin comfort, whereas imitated silk made from polyester offers much higher strength and durability for long-lasting wear.

| Property | Natural Silk | Imitated Silk (e.g., Polyester) |

| Fiber Origin | Protein filament from silkworms. | Chemically synthesized polymers (e.g., PET) or regenerated cellulose. |

| Strength & Durability | Strong but can degrade with sweat/UV light. | Generally higher tensile strength; excellent resistance to abrasion, mildew, and sunlight. |

| Care & Maintenance | Often requires dry cleaning or very gentle hand washing. | Most are machine washable, wrinkle-resistant, and quick-drying. |

| Moisture Management | Highly absorbent (up to 30% of its weight), feels cool. | Low absorbency (can feel clammy); moisture-wicking versions are engineered. |

| Thermal Regulation | Warm in winter, cool in summer due to natural properties. | Less breathable; can retain heat unless specifically engineered. |

| Cost | Very high due to labor-intensive production. | Significantly more affordable and price-stable. |

| Environmental Impact | Biodegradable but resource-heavy (land, water, feed). | Depends on fiber; petroleum-based synthetics are not biodegradable but recycling streams are growing. |

Popular Applications of Imitated Silk Fabrics

The versatility of imitated silk fabric has led to its adoption across diverse industries. Its ability to blend aesthetic appeal with functional resilience makes it a preferred choice for manufacturers.

Fashion and Apparel

- Women's Fashion: A cornerstone for affordable luxury evening wear, including dresses, blouses, skirts, and scarves. It allows for flowing silhouettes and a premium look without a prohibitive cost.

- Lingerie and Loungewear: Nylon-based imitated silk is prized for its smooth, gentle hand-feel against sensitive skin, making it ideal for slips, robes, and pajamas.

- Linings: Widely used as a slick, durable lining for jackets, coats, and suits, improving comfort and ease of wear. For instance, finding the best lining fabric for jackets often leads to high-quality nylon or polyester imitated silk due to its strength and smoothness.

Home Textiles and Décor

- Curtains and Drapes: The fabric's excellent drape and luster create elegant window treatments. Its better sun resistance compared to natural silk prevents rapid degradation.

- Bedding and Cushions: Used in duvet covers, pillowcases, and decorative cushions to add a touch of opulence with easier care requirements.

Technical and Outdoor Goods

This is where the functional prowess of synthetic fibers shines. Our expertise in outdoor functional fabrics directly applies here.

- Luggage and Bags: Durable jacquard luggage fabric often utilizes imitated silk weaves. The designs are intricate and stylish, while the polyester or nylon base provides the tear-strength and abrasion resistance needed for travel.

- Outdoor Gear: Certain lightweight outer shells or linings in outdoor apparel may use imitated silk textures for specific performance characteristics, combining a soft feel with weather resistance.

- Specialty Items: Used in costumes, flags, and ceremonial items where a specific sheen and drape are required alongside durability.

Choosing the Right Imitated Silk: A Buyer's Guide

Not all imitated silk fabric is created equal. Key specifications determine its suitability for your project. For example, understanding the properties of polyester satin fabric—such as its weight, weave density, and finish—is crucial when selecting a material for a sleek evening gown versus a sturdy bag lining.

Critical Specifications to Evaluate

Fiber Content and Blend Ratio

- 100% Polyester: For maximum durability, wrinkle resistance, and value.

- Polyester-Rayon Blends: Balance the durability of polyester with the superior drape and absorbency of rayon.

- 100% Nylon: For exceptional strength, abrasion resistance, and a bright luster.

Fabric Weight and Denier

- Lightweight (e.g., 30-70 gsm): Ideal for delicate apparel, linings, and scarves.

- Medium Weight (e.g., 70-120 gsm): Versatile for dresses, blouses, and lighter home décor.

- Heavy Weight (e.g., 120+ gsm): Suitable for durable jacquard luggage fabric, structured garments, and upholstery.

Weave Type and Finish

- Satin Weave: Creates the classic, glossy surface associated with silk. Inquiring about the properties of polyester satin fabric is key here.

- Chiffon Weave: Produces a sheer, gauzy, and crinkled texture.

- Jacquard Weave: Allows for intricate, raised patterns woven directly into the fabric.

- Finish: Look for terms like "peach skin" (suede-like), "matte," or "crinkle" to define the final hand-feel and appearance.

Importance of Finishing Processes

The journey from raw synthetic yarn to luxurious imitated silk fabric hinges on finishing. Processes like:

- Calendering: Where fabric is passed through hot rollers to smooth and polish its surface, enhancing sheen.

- Sanding/Brushing: To create a softer, peach-skin texture.

- Dyeing and Printing: Ensuring color vibrancy and pattern clarity.

- Wash Treatments: To pre-shrink fabric or induce a crinkled effect.

These technical steps require expertise and proper equipment—such as the water jet looms and twisters in our facility—to ensure consistent, high-quality results that truly mimic the desired silk-like qualities.

Innovations and Sustainability in Imitation Silk

The industry is continuously evolving to address performance gaps and environmental concerns. A significant area of development is moisture wicking imitation silk, which incorporates special fiber engineering or finishes to draw sweat away from the body, addressing the traditional downside of low absorbency in synthetic silks. This makes it suitable for activewear or formal wear in warmer climates. Furthermore, the development of recycled polyester and bio-based polymers is paving the way for more eco-conscious versions of imitated silk, reducing reliance on virgin petroleum and lowering the carbon footprint of these versatile fabrics [1].

FAQ: Frequently Asked Questions

1. Is imitated silk fabric breathable?

Breathability varies by fiber. Standard polyester imitated silk has lower breathability than natural silk or cotton. However, versions specifically engineered with micro-perforations, moisture-wicking finishes, or blended with more breathable fibers like rayon can significantly improve air circulation and comfort.

2. How do I properly care for and wash imitated silk garments?

Always check the care label first. Generally, most imitated silk is machine washable on a gentle cycle in cold water with mild detergent. Turn garments inside out to protect the surface. Avoid bleach and fabric softeners. Tumble dry on low heat or, preferably, hang to dry. Iron on a low synthetic setting if needed.

3. Can imitated silk look cheap?

It can, if low-quality fibers and finishes are used. High-quality imitated silk fabric from reputable manufacturers uses fine denier filaments, precise weaving, and sophisticated finishing (like calendering and sanding) to achieve a deep, subtle luster and soft hand that is virtually indistinguishable from mid-grade real silk to the untrained eye. The key is in the quality of production.

4. What are the best uses for moisture-wicking imitation silk?

Moisture wicking imitation silk is excellent for applications where style meets mild physical activity or warm environments. Think of liner fabrics in performance jackets, travel clothing, summer blouses, dancewear, or high-end sportswear where a sleek, silky appearance is desired alongside functional sweat management.

5. Why choose imitated silk over real silk for lining a jacket?

When selecting the best lining fabric for jackets, imitated silk (especially nylon or polyester) is often superior due to its:

- Durability: Withstands the friction from arm movement better.

- Strength: Less likely to tear during dressing or with keys/items in pockets.

- Smoothness: Allows outer garments to slide on and off easily.

- Cost-Effectiveness: Reduces the overall cost of the garment significantly.

- Ease of Care: Makes the entire jacket more likely to be machine washable.

Conclusion

Imitated silk fabric stands as a testament to textile innovation, successfully bridging the gap between opulent aesthetics and modern-day practical needs. From enabling affordable luxury evening wear to forming the backbone of durable jacquard luggage fabric, its applications are vast and growing. By understanding the nuances of fiber content, weave, finish, and key properties of polyester satin fabric, buyers and designers can leverage this versatile material to its full potential. For projects demanding a blend of beauty, resilience, and value—whether it's finding the best lining fabric for jackets or exploring advanced moisture wicking imitation silk—this engineered fabric offers a compelling and sophisticated solution.

References

[1] Textile Exchange. (2022). *Preferred Fiber and Materials Market Report*. Retrieved from Textile Exchange website. (This source is cited for general context on innovations in recycled and bio-based synthetic fibers, a trend impacting the imitation silk sector).

English

English русский

русский عربى

عربى