Printing Polyester Fabric: A Complete, Practical Playbook

2025-08-18

Polyester-Focused Fundamentals for Reliable Results

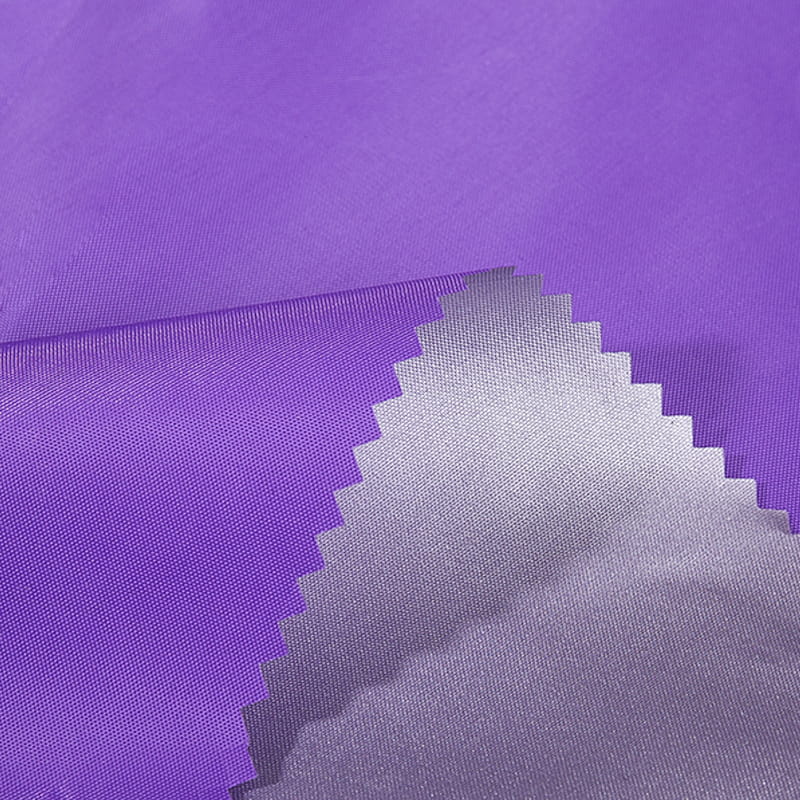

Polyester is a synthetic fiber with a smooth, hydrophobic surface and a relatively low moisture regain. Those traits make colorants behave differently compared with cellulose fibers. In practice, Printing Polyester Fabric succeeds when you align three elements: a dye or ink chemistry able to bond with polyester, enough energy to drive that bonding, and a surface workflow that keeps the fabric stable while you transfer or fix color. The most popular pathway is dye-sublimation, where disperse dye on a carrier (transfer paper) is turned into gas and diffused into polyester at high temperature. This is the backbone of sublimation printing polyester fabric step by step processes used for sportswear, flags, soft signage, and interior prints that need saturated color with a soft hand and excellent rub resistance.

Why polyester prints differ comes down to molecular affinity: disperse dyes are non-ionic, low-molecular-weight compounds that physically dissolve into the amorphous regions of polyester when heat provides mobility. In contrast, pigment systems sit on top and need binders; they can work on polyester but usually trade maximal vibrancy for versatility and simpler aftercare. Disperse-direct printing (printing the dye directly to the fabric and then thermally fixing) removes the transfer step but places higher demands on fabric handling to avoid strike-through and cockling. Heat-transfer films and hybrid transfers can decorate polyester too, albeit with a different hand and durability profile.

Method Overview: What Changes on Polyester

Compared with cotton, polyester tolerates higher temperatures but is sensitive to glazing and press marks. Sublimation thrives because the dye becomes a gas and diffuses into the fiber, leaving no noticeable film. Pigment workflows succeed when the binder system is optimized for low surface energy substrates. Disperse-direct methods need excellent control of pre- and post-heat to lock in shade and prevent off-gassing artifacts. The choice is ultimately a balance of color depth, hand feel, run length, and available equipment.

When to Choose Each Method

- Sublimation: maximum color pop, soft hand, excellent abrasion resistance, ideal for 80–100% polyester.

- Disperse direct: efficient for long runs, continuous equipment, and roll-to-roll finishing lines.

- Pigment on polyester: flexible substrate range, simpler workflow, slightly flatter color in exchange for versatility.

- Transfers/films: sharp logos, small runs, variable substrates, different hand and breathability.

Put plainly, sublimation usually beats pigment on vibrancy and hand, while pigment can win on substrate flexibility and simplified logistics. Disperse-direct often beats transfer on speed for long runs, but transfer wins on small-batch agility and reduced waste during changeovers.

| Method | Color Vibrancy | Hand Feel | Small-Batch Agility | Typical Use |

|---|---|---|---|---|

| Sublimation (Transfer) | Very High | Soft, In-Fiber | Excellent | Sportswear, Soft Signage |

| Disperse Direct | High | Soft | Moderate | Long Roll Runs |

| Pigment on Polyester | Moderate | Surface Film (thin) | Good | Mixed Substrates |

| Transfer Films | High (solid colors) | Noticeable Film | Excellent | Logos, Numbers |

Color Management and Device Tuning

Consistency on polyester hinges on color management. Because transfer papers, presses, and fabrics vary, a “universal” profile is rarely optimal. Instead, you build a repeatable workflow around profiling and ink limiting that reflects your actual materials. Many teams start by selecting or creating a profile tailored to their transfer paper, ink set, and press conditions—the spirit of best ICC profile and ink settings for polyester. With the right profile, you’ll manage channel usage to avoid over-inking (which can cause cockle on paper, fuzzy edges, or smoky haze when excess dye outgasses).

Building the Workflow

- Stabilize variables first: same lot of paper and fabric, press warmed and equilibrated, consistent room humidity.

- Choose a target print condition (resolution, pass count, carriage speed) that your device can sustain in production.

- Measure primaries and overprints; set an ink limit where solid patches look saturated but edges remain crisp.

- Create or select an ICC profile for that exact condition; lock it into your RIP presets so operators cannot drift.

- Validate with a miniature production panel and a transfer on real polyester under real press settings.

Resolution and Dithering Choices

Higher resolution can reduce grain but may drive more ink, so balance clarity against cockle risk. Error-diffusion dithers can hide banding on areas of smooth tone; clustered-dot patterns may offer crisper microtype. A practical approach is to maintain two qualified modes—one for fine art or small text, one for speed—and bind each to a unique profile and queue.

Proofing and Validation

Before committing a run, print a step wedge and a customer-critical swatch set. Transfer those to a fabric offcut and compare in a controlled lightbox. Describe the difference in words—“Mode A shows slightly deeper blues with smoother gradients; Mode B is faster but a touch grainier”—then lock the choice.

| Setting | Conservative Mode | Production Mode | Trade-Off |

|---|---|---|---|

| Resolution | High (e.g., 1440) | Medium (e.g., 720) | Sharpness vs. Throughput |

| Ink Limit | Lower to avoid cockle | Optimized for saturation | Stability vs. Pop |

| Dither | Error Diffusion | Hybrid/Clustered | Fine Gradients vs. Speed |

Heat, Pressure, and Surface Control on Polyester

Thermal control is where many shops win or lose print quality. Sublimation requires enough energy to turn dye into gas and drive it into the fiber without scorching the fabric or leaving press marks. Practitioners often ask for the canonical numbers: the widely shared rule-of-thumb for heat press temperature for polyester sublimation is a mid-to-high range paired with moderate pressure and a dwell long enough to fully gas out the dye. Equally critical are flatness, uniform contact, and anti-ghosting strategy—especially on stretchy knits and textured weaves.

Press Windows and Practical Ranges

While exact recipes vary by dye set and fabric, think in windows rather than single numbers. Light, tight-knit polyester often tolerates shorter dwell at higher temperature; heavier, brushed, or textured goods may like slightly longer dwell with careful pressure to preserve loft. Write these differences down, compare them in sentences (“Setting X yielded deeper blacks but left platen sheen; Setting Y preserved texture with only a slight sacrifice in density”), then verify with a table so operators can see the decision at a glance.

| Fabric Type | Temperature (°C) | Time (s) | Pressure | Notes |

|---|---|---|---|---|

| Lightweight Knit | 185–200 | 40–60 | Medium | Fast transfer; watch edge ghosting |

| Midweight Interlock | 185–200 | 50–70 | Medium-Firm | Balanced density and flatness |

| Brushed/Lofted | 180–195 | 60–80 | Light-Medium | Preserve pile; use protective sheets |

| Textured Weave | 185–200 | 60–90 | Medium | Extra anti-ghost measures |

Preventing Ghosting, Scorching, and Marks

- Pre-lint and pre-press fabric briefly to drive off residual moisture and reduce lint contamination.

- Use a clean, smooth liner; change liners frequently to avoid dye offset.

- Tack transfer paper at two corners or use vacuum/frames to stop micro-shifts.

- Cool under weight or on a flat rack to limit post-press warping and color lift from hot stacking.

Fixtures and Surface Prep

Jigs, frames, and soft pads distribute pressure evenly across seams and hems. A soft underlay can prevent platen embossing on textured goods, while a rigid frame keeps panels square for accurate alignment. These simple controls often raise quality more than tiny adjustments to time and temperature.

Durability, Wash Fastness, and Aftercare

Customers experience quality through how a product ages. That is why wash fastness for polyester fabric prints matters as much as day-one color. Sublimation embeds colorants into the fiber, so washing mainly challenges fabric integrity rather than an ink film. Pigment and transfer systems rely on binder films or adhesives, so their wash profile depends on film strength and mechanical abrasion. To manage expectations and reduce returns, run in-house tests that simulate real use and translate the results into plain-language care labels.

Simple In-House Testing

- Washing: 5–10 cycles at a standard program; compare shade and edge clarity to retained control samples.

- Rubbing: dry and wet crock tests on representative printed areas.

- Light exposure: window test for a week on duplicates to check early fade tendencies.

- Stretch and recovery: mark a grid line, stretch to a fixed percentage, and inspect for crack or halo.

Pre- and Post-Treatments That Help

For sublimation, keep pre-press moisture low; moisture can cause blurring and uneven density. For pigment systems, ensure the recommended pre-treatment and cure conditions; under-cure is the most common reason for early wash failures. Post-wash advice—turn garments inside out, wash cool, avoid softeners for the first few cycles—extends life with negligible inconvenience.

In words: sublimation generally outperforms pigment on polyester for repeated washing because the color resides within the fiber rather than on top. Pigment can still achieve acceptable durability with robust binders and proper curing, especially for low-abrasion use.

| Method | Wash Performance | Abrasion Resistance | Typical Care |

|---|---|---|---|

| Sublimation | Excellent (in-fiber) | High | Cool wash; minimal restrictions |

| Pigment | Good–Moderate (film-based) | Moderate | Gentle wash; avoid harsh friction |

| Transfer Films | Good (if properly applied) | Moderate–High (depends on film) | Turn inside-out; gentle cycle |

Packaging and Customer Instructions

- Include a small care card with wash temperature, drying guidance, and ironing cautions.

- Ship fully cooled goods to avoid trapped heat causing offset or panel sticking.

- For stacked panels or rolls, interleave with clean sheets to prevent blocking.

Safer Chemistry and Lower-Impact Choices

Print quality and environmental performance are compatible goals. Many teams now look for eco-friendly printing on polyester fabric practices that reduce energy, waste, and exposure without compromising color. Sublimation already avoids water-heavy wet processing, but you can still shrink impact through smarter press cycles, efficient nesting, and paper selection. For pigment, prioritize low-VOC binders and processes that avoid unnecessary heat dwell. Across methods, the keys are process efficiency and transparency.

Energy, Waste, Consumables

- Batch warm-ups and avoid idling presses; schedule jobs to minimize thermal cycling.

- Nest panels tightly and trim digitally to reduce paper offcuts.

- Collect and recycle transfer paper cores and cartons; segregate clean offcuts where local programs allow.

Safer Dyes, Inks, and Auxiliaries

Choose chemistries aligned with recognized restricted-substance lists and maintain certificates from suppliers. Avoid unnecessary additives; each extra chemical is another variable to control and document. Clear work instructions reduce mis-dosing and spills, which helps both quality and safety.

Compliance and Documentation

Keep a concise file: safety data sheets, lot numbers, process setpoints, and your latest test results. This not only supports claims about durability and safety but shortens ramp time when you onboard new operators or audit a new fabric.

English

English русский

русский عربى

عربى