What is Twisted Yarn Fabric and How is it Made?

2025-08-12

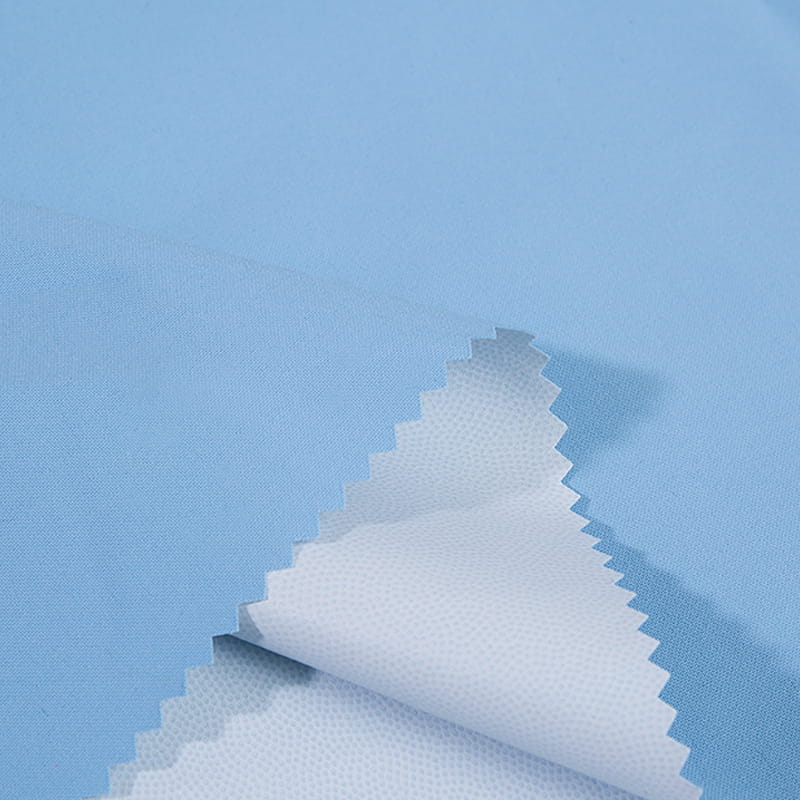

Twisted Yarn Fabric is a type of textile woven from yarns that have undergone a special twisting process. Twisting refers to applying rotational force to the yarn fibers, making the fibers wrap around each other and producing a certain twist level, which improves the fabric’s strength, elasticity, and stability. Different combinations of twist levels and yarn materials allow Twisted Yarn Fabric to present diverse characteristics in appearance, texture, and functionality.

1. Basic Characteristics

- High structural stability: Increased friction between fibers, making them less likely to loosen.

- Excellent abrasion resistance: Suitable for textiles that are frequently used.

- Strong three-dimensional appearance: The fabric surface displays unique textures and luster.

2. Manufacturing Process

-

Fiber Selection

Can be made from natural fibers (such as cotton, linen, silk) or synthetic fibers (such as polyester, nylon).

-

Yarn Twisting

Twist level (Twists Per Inch, TPI) is set according to design needs. Twist direction can be S-twist or Z-twist, affecting the fabric’s grain and hand feel.

-

Weaving or Knitting

Twisted yarns are used in woven or knitted fabric production.

-

Finishing

Includes setting, dyeing, and softening treatments to enhance appearance and performance.

3. Parameter Comparison Example

| Parameter Type | Low-Twist Twisted Yarn Fabric | High-Twist Twisted Yarn Fabric |

|---|---|---|

| Twist Range (TPI) | 4–8 TPI | 12–20 TPI |

| Hand Feel | Soft, fluffy | Tight, crisp |

| Abrasion Resistance | Medium | High |

| Elastic Recovery | High | Medium |

| Application Scenarios | Casual wear, bedding | Workwear, upholstery, industrial fabrics |

4. Key Factors Affecting Finished Fabric

- Twist level: Directly impacts the stiffness and surface effect of the fabric.

- Fiber type: Natural fibers offer better breathability, synthetic fibers provide higher durability.

- Weaving density: Higher density increases abrasion resistance but reduces breathability.

Key Characteristics of Twisted Yarn Fabric

Twisted Yarn Fabric is well known for its unique twisted yarn structure, which not only changes the appearance of the fabric but also significantly influences its performance. Twisting creates stronger friction and support between fibers, giving the fabric multiple characteristics that meet the needs of different industries.

1. Strength and Durability

Because the fibers are tightly bound together, Twisted Yarn Fabric has higher tensile strength and abrasion resistance, capable of withstanding frequent friction and long-term use.

Comparison Example

| Feature | Regular Untwisted Fabric | Twisted Yarn Fabric |

|---|---|---|

| Tensile Strength | Medium | High |

| Abrasion Resistance | Medium | High |

| Breaking Elongation | High | Medium-high |

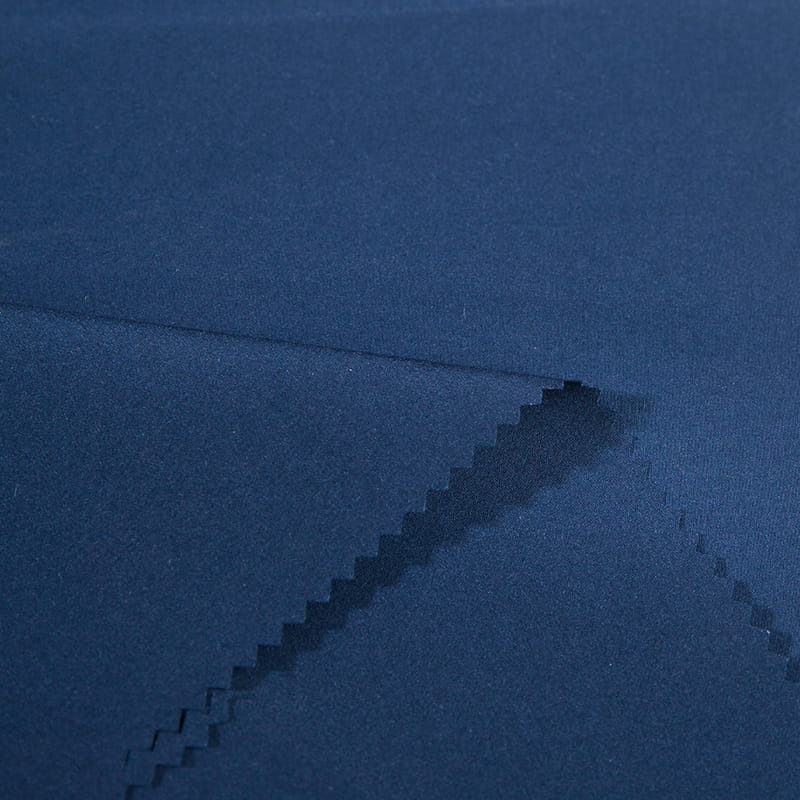

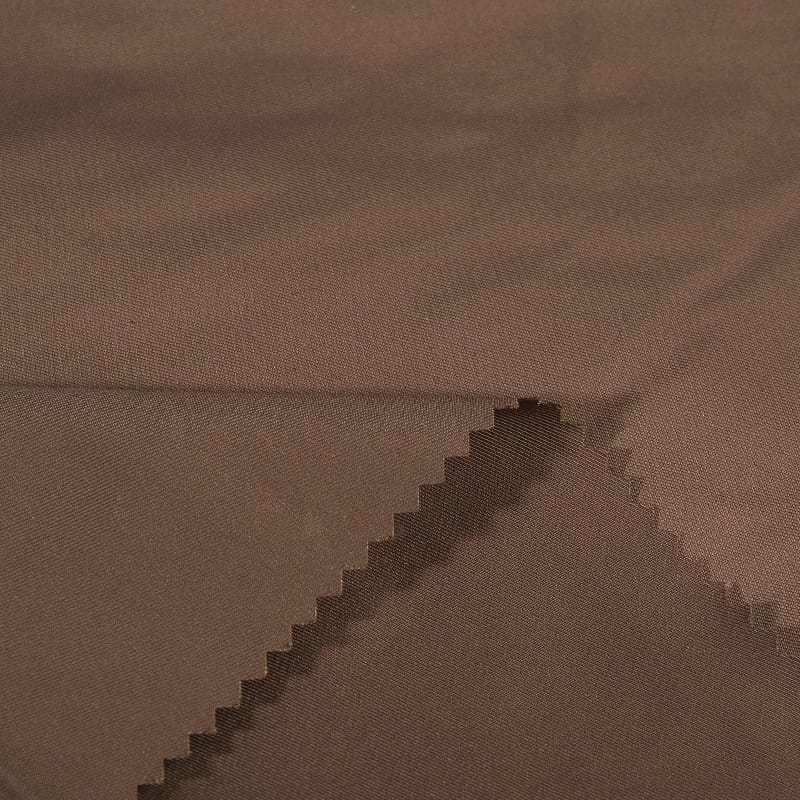

2. Unique Texture and Visual Effect

Twisted yarns create slight three-dimensional grain during weaving, giving the fabric a richer texture and luster, which can enhance its aesthetic and tactile appeal.

3. Elasticity and Shape Retention

Twisted Yarn Fabric has good elastic recovery to some extent, making it less likely to lose its shape due to stretching or compression—especially useful for products that require a crisp appearance.

Elasticity and Recovery Comparison

| Feature | Regular Yarn Fabric | Twisted Yarn Fabric |

|---|---|---|

| Elastic Recovery Rate | Medium | High |

| Shape Retention | Medium | High |

4. Moisture Absorption and Breathability

Depending on fiber type and twist level, Twisted Yarn Fabric’s moisture absorption and breathability can vary:

- Low twist: More space between fibers, better breathability and absorption.

- High twist: Tighter structure, slightly lower breathability but better abrasion resistance.

5. Touch and Comfort

Twisted yarns can produce a wide range of hand feels—from soft and fluffy to tight and crisp—meeting needs from casual wear to functional and industrial uses.

Exploring the Versatility of Twisted Yarn Fabric: Applications and Benefits

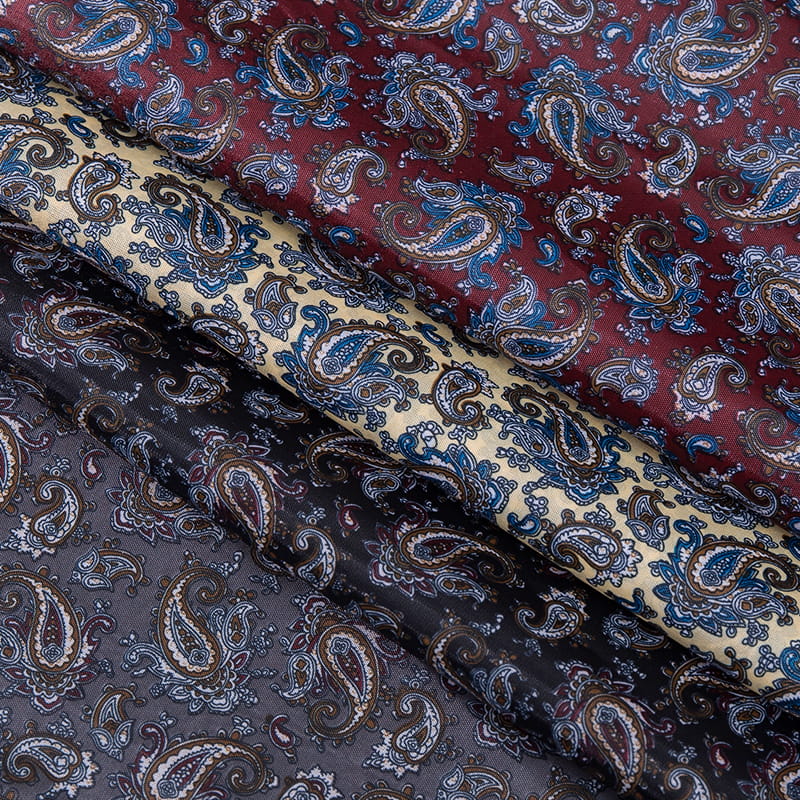

The versatility of Twisted Yarn Fabric comes from its unique twisted structure and adjustable weaving methods, enabling it to meet both aesthetic and high-performance requirements. Various combinations of twist levels, fiber types, and weaving densities make this fabric suitable for multiple industries, bringing significant functional advantages.

1. Applications in the Fashion and Apparel Industry

- Casual wear: Low-twist Twisted Yarn Fabric offers a comfortable and breathable wearing experience.

- Formal wear: High-twist fabrics maintain a crisp shape, ideal for shirts and suits.

- Functional clothing: High strength and abrasion resistance make it suitable for workwear and sportswear.

2. Applications in Home and Interior Decor

- Curtains and soft furnishings: Rich texture and luster enhance interior aesthetics.

- Upholstery fabrics: High abrasion resistance extends product lifespan.

- Bedding and cushions: Soft touch and good breathability improve comfort.

3. Industrial and Technical Applications

- Industrial protective fabrics: High strength and durability for machine covers, transport packaging fabrics, etc.

- Outdoor materials: Weather resistance and structural stability for tents, sunshades, and more.

4. Advantages of Twisted Yarn Fabric in Different Industries

| Industry | Main Advantages | Recommended Twist Range | Performance Highlights |

|---|---|---|---|

| Apparel | Comfort, shape retention | Low–medium twist | Soft, breathable, durable |

| Home Decor | Aesthetic appeal, abrasion resistance | Medium–high twist | Rich texture, long lifespan |

| Industrial | High strength, durability | High twist | Tensile resistance, abrasion resistance |

| Outdoor | Weather resistance, protection | Medium–high twist | Windproof, water-resistant, stable |

5. Key Overall Benefits

- Durability: Tight twisted yarn structure extends service life.

- Design versatility: From soft casual styles to robust industrial-grade options.

- Easy processing: Compatible with various dyeing and finishing techniques.

- Sustainability potential: Can be made from natural or recycled fibers.

Care and Maintenance Tips for Twisted Yarn Fabric

Twisted Yarn Fabric is valued for its structural stability and distinctive texture created by twisted yarns. To maintain its best condition, proper care and maintenance are essential. Whether used in apparel, home textiles, or industrial products, correct washing and storage methods will prolong its lifespan and preserve its appearance and performance.

1. Washing Recommendations

- Gentle washing: Use cold or lukewarm water to avoid heat damage to fibers.

- Low mechanical action: Choose gentle wash cycles to reduce fiber surface wear.

- Mild detergents: Avoid strong alkaline or chlorine bleach products to protect twist and color.

Recommended Washing Temperatures by Fiber Type

| Twisted Yarn Fabric Material | Recommended Water Temp | Machine Washable | Bleach Safe |

|---|---|---|---|

| Polyester | ≤ 40°C | Yes (gentle cycle) | No |

| Nylon | ≤ 30°C | Yes (gentle cycle) | No |

| Blends | ≤ 30°C | Yes (gentle cycle) | No |

2. Drying and Ironing

- Air drying: Avoid prolonged direct sunlight to prevent fiber aging or color fading.

- Low-temperature ironing: If ironing is needed, use low heat and place a cloth between the iron and the fabric to prevent direct heat damage.

3. Storage Suggestions

- Store in a dry, ventilated place to prevent mold and odors.

- For long-term storage, use dust covers or fabric bags to protect from light and dust.

4. Quality Assurance of Twisted Yarn Fabric in Production and Finishing

As a family-owned plant operating for over 20 years,The company specializes in producing polyester nylon fabrics and linings for outdoor functional clothing lines, women’s silk lines, jacquard luggage fabrics, and outdoor goods. The company operates 300 self-owned water jet looms and 100 matching twisters, bringing mature expertise in weaving and twisting processes to ensure the twist stability, colorfastness, and abrasion resistance of Twisted Yarn Fabric.

- Production advantages: Large equipment capacity enables bulk orders and fast delivery.

- Quality assurance: Years of experience in textile manufacturing and finishing ensure the fabric resists deformation, fading, or pilling during care.

- Customization capability: Accepts custom samples from international clients to meet diverse market demands.

- Factory visits welcome: Located in China, open to global customers for on-site visits and cooperation.

English

English русский

русский عربى

عربى