Clothes Fabrics

Clothes Fabrics are key materials for making all kinds of clothing. They are of various types, each with its own characteristics, meeting people's different needs for clothing. Natural fabrics such as cotton, linen, silk, wool, etc., with their good breathability and moisture absorption, provide people with a comfortable wearing experience. Among them, cotton fabrics have good breathability, strong moisture absorption, and are comfortable to wear; linen fabrics have extremely high strength, good thermal conductivity and breathability; silk fabrics are light, soft, colorful, noble and elegant; wool fabrics are wrinkle-resistant, wear-resistant, and have strong warmth retention. The choice of clothing fabrics should be based on personal needs, seasonal changes, occasions and other factors to ensure comfort and beauty of wearing.

KEEP IN TOUCH

-

In the dynamic world of textiles, innovation is constant. Among the many advanced materials available, combined polyester fabric stands out for its ve...

-

Understanding Fabric Terminology: Combined, Pure, and Blended The world of synthetic textiles can be complex, with terminology often used interchangea...

-

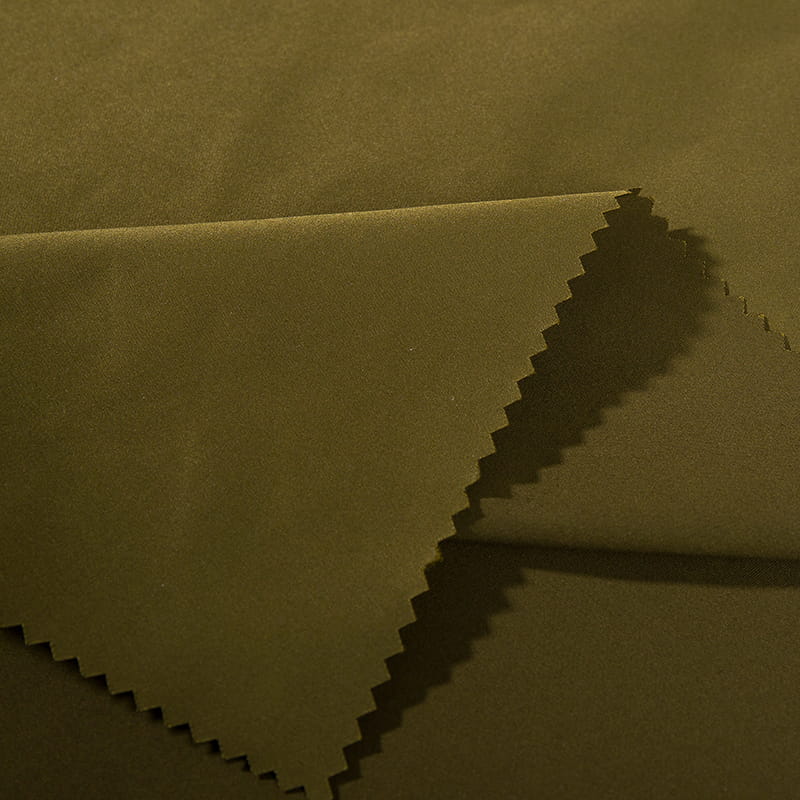

In the world of performance textiles, Satin Poly Pongee stands out for its unique combination of a soft, lustrous hand feel, inherent durability, and ...

-

For over two decades, our family-owned textile mill has specialized in creating high-performance and aesthetically pleasing fabrics. With deep experti...

What role does fabric testing play in ensuring the durability, colorfastness, and performance of clothing fabrics, particularly in demanding or specialized applications?

Fabric testing plays a crucial role in ensuring the durability, colorfastness, and performance of clothing fabrics, especially in demanding or specialized applications. Here's how:

Durability Assessment: Fabric testing involves subjecting the fabric to various mechanical tests to evaluate its strength, abrasion resistance, tear resistance, and pilling resistance. These tests simulate real-world conditions to assess how well the fabric withstands wear and tear, ensuring it remains durable and long-lasting, particularly in garments worn in high-activity or rugged environments.

Colorfastness Testing: Colorfastness testing evaluates the fabric's ability to retain its color when exposed to different conditions such as washing, sunlight, perspiration, and dry cleaning. This ensures that the fabric maintains its aesthetic appeal and does not fade or bleed excessively over time, especially in garments subjected to frequent washing or outdoor exposure.

Dimensional Stability Testing: Dimensional stability testing measures how well the fabric maintains its shape and size after exposure to various factors such as washing, heat, and tension. This ensures that the fabric does not shrink, stretch, or distort significantly during use, maintaining the integrity of the garment's fit and appearance.

Moisture Management Testing: For fabrics used in activewear or performance apparel, moisture management testing assesses the fabric's ability to wick moisture away from the skin and dry quickly. This helps prevent discomfort caused by sweat buildup and maintains the wearer's comfort and performance during physical activity.

How do advancements in textile manufacturing techniques contribute to the development of innovative fabrics for clothing?

Advancements in textile manufacturing techniques play a crucial role in driving innovation in the development of fabrics for clothing.

New Fiber Production Methods: Innovative manufacturing techniques enable the creation of new types of fibers with enhanced properties. For example, nanotechnology allows for the production of ultra-fine fibers with unique characteristics such as improved strength, moisture-wicking, and antimicrobial properties.

Specialized Finishing Processes: Textile manufacturers employ advanced finishing processes to modify the surface properties of fabrics. These processes include treatments such as water-repellent coatings, flame retardants, UV protection, and anti-static finishes, enhancing the functionality and performance of the fabric for specific applications.

Weaving and Knitting Innovations: Advancements in weaving and knitting technologies allow for the creation of fabrics with intricate patterns, textures, and structures. Techniques like 3D knitting and jacquard weaving enable the production of fabrics with customizable designs and integrated features such as compression zones, ventilation panels, and stretch properties.

Digital Printing and Dyeing: Digital printing technologies have revolutionized the textile industry by enabling high-resolution printing directly onto fabrics. This allows for intricate patterns, vibrant colors, and photo-realistic designs to be printed with precision, expanding creative possibilities in fabric design and customization.

English

English русский

русский عربى

عربى